Elevate your design and manufacturing processes with Autodesk Fusion

Swiss watches represent one of the high points of artisanal craft in all the world: For centuries, their fine mechanisms have relied on the most delicate balance of art and engineering in the cutting and shaping of dials, springs, and other components. But what if those pieces could be created in resin using 3D printing?

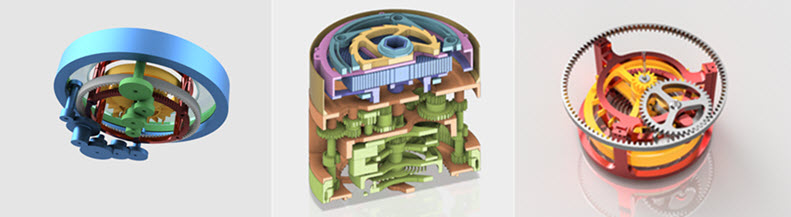

That’s what Christoph Laimer, a Swiss engineer (but with no training in making watches), has done with his tourbillon-based timepiece.

Horological History Meets 21st-Century 3D Printing

The tourbillon mechanism was created at the end of the 18th century by legendary watchmaker Abraham-Louis Breguet to improve the accuracy of timepieces. What makes Laimer’s work a big deal? Horologist Nicholas Manousos explains the significance in his overview of Laimer’s work:

The tourbillon — a 200+ year old invention designed by one of the greatest watchmakers to ever live, which for most of its history has been practically synonymous with hand-craftsmanship and high end watchmaking, has been produced in a working watch with a 3D printer.

The watch is a little bulky and not especially accurate, but Manousos doesn’t care. He’s still impressed that an entire timepiece, including tourbillon, has been 3D printed — and affordably, to boot.

From Scientific Software to Mechanical Design

Laimer came to timepiece design and 3D printing after twenty years of work as a software engineer, most recently developing programs for the life sciences. He became interested in watches because he wanted to 3D print something with a purely mechanical function.

Watches are great for this, he says, because “you can feel how life works” with them. That’s a big contrast from writing software, where everything happens invisibly in the depths of the computer, and Laimer has welcomed the change.

After evaluating various CAD applications, he gravitated to Fusion 360 to make his design. He was happy to discover that the program had a script to generate gears. The sketch functions — and especially the ability to go back in time and refine sketches — also helped him create the watch’s escapement mechanism. Instead of needing to use a compass and set square, he used online Fusion 360 tutorials to quickly teach himself how to shape the mechanism and design its teeth.

Sharing His Work with the Community of Makers

Because he had never had any particular connection with timepieces before, Laimer had to do a lot of research on how a watch works, then spend even more time making it 3D printable. He’s now shared all the files so that anyone can take advantage of his hard work.

In the future, Laimer is thinking about going smaller and more complex with his designs, focusing on a ‘really wearable’ watch. Given his work on the tourbillon, it makes you wonder whether we’ll all be wearing one of his designs soon!