Elevate your design and manufacturing processes with Autodesk Fusion

“Robotics Is Closed,” the EngiMake website declares. “Let’s Make It Open.”

Startup EngiMake, based in London, is the brainchild of founders Josh Elijah and Jack Scott-Reeve—engineering graduates who are using Fusion 360 to make robotics accessible for a wider audience of makers.

Making Robotics Easy for Everyone

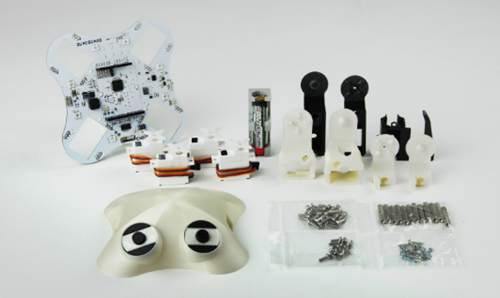

Their vehicle for their vision is the QuadBot, a DIY robotics assembly kit with programmable Arduino-based electronics and 3D-printable parts. The kit is meant to be accessible for novice makers, yet challenging enough for those who already have more skills.

The impetus for the product is simple, as Elijah explains: “There wasn’t a robotics package I was happy with that was easy enough to use and complex enough to do interesting stuff with.”

As an undergraduate at Manchester University, he says, he founded the school’s robotics society. The design of the QuadBot, which looks something like a four-legged spider, builds on work that Elijah did in 2012 while working at National Instruments. (When he recalls the initial design, he laughs and says, “It looked like it was held together with chewing gum.”)

Along the way, Elijah began teaching robotics to others and discovered that “If you know how, it’s very easy.” He and Scott-Reeve, who also studied at Manchester, want their product to embody that. “You take something like robotics that people are afraid of,” Elijah says, “and you make it super-easy to play with.”

Paying Attention to Every Design Detail

In recent months, Elijah has focused on programming the robot to walk while Scott-Reeve has worked in Fusion 360 to get the parts to snap together easily. “We could get it working very quickly,” Elijah says, “but it wouldn’t look nice, and wouldn’t be intuitive.” They’re taking the harder approach of refining  everything so that the robot is more robust and user-friendly. For example, they have spent lots of time designing a better circuit board, which is fully labeled so that even beginners can understand

everything so that the robot is more robust and user-friendly. For example, they have spent lots of time designing a better circuit board, which is fully labeled so that even beginners can understand

“You have to be mad with the attention to detail on the product,” Elijah adds. “If we want to make this the de facto Arduino of robotics, it has to live up to that.”

After trying Blender, Rhino, and other design software, they happily settled on Fusion 360, especially because it allows them to combine parametric modeling for the robot’s legs with sculpting for the robot’s curved dome. “The fact that you can do that in one software is mad,” Elijah says with a smile.

He also praises the ease of exporting and importing files, the ability to share designs online, and the rendering and animation features that allow him and Scott-Reeve to create detailed 3D models of the robot. “I love the animation in Fusion 360,” he says. “I’m a bit of a geek when it comes to that.”

He sums up his experience with Fusion 360 by saying “It gets rid of headaches. It’s anti-headache software.”

Getting a Design Startup off the Ground

In the second half of 2015, Elijah got into FabLab in London, then brought in Scott-Reeve. Elijah says that the six months they spent there “incubated not only our idea, but also our confidence in making money that wasn’t 9-to-5.”

In the spring of 2016, Elijah left the engineering Ph.D. program at Manchester to focus on EngiMake. Despite occasional doubts, he and Scott-Reeve have been making it work, in part by doing freelance electronics design on the side to keep cash flowing.

They also received £2,00 from their alma mater, and in July of this year moved into the Makerversity space in central London. “You can find the money,” Elijah says. “You’ve got to live hand-to-mouth for a bit, but there is money out there.”

Kickstarter and Beyond

Over the past several months, the growing EngiMake team has been working toward the launch of a Kickstarter project, which they see as the real test of the QuadBot’s appeal. For all the positive feedback they’ve received, Elijah says, “It doesn’t really hold much sway until people are willing to pay for it.”

The Kickstarter effort has meant endless work on the QuadBot’s software and hardware, but also on the company’s website and online tutorials, as well as business aspects such as sourcing for components, manufacturing relationships, and marketing promotions.

As Elijah points out, “There’s an immense amount of work to do,” including lots of learning on the fly for engineers with little background in business. “I’ve never worked so hard in my life,” he adds.

Their hope in to hit a sweet spot in terms of pricing, capabilities, and complexity for their robot. If they succeed, that will allow them to grow beyond their initial market of makers to reach younger students.

“We want to hit schools with this,” Elijah says. “That’s where I want it to go, but I don’t want to do this until I’ve proven it.”

Opening Up Robotics for the Masses

Elijah finds all the hard work personally gratifying. “I know this is what I want to do,” he says, “because I love doing it.” Beyond that, though, he also has a vision for what EngiMake can accomplish in the world:

“I really want to open up robotics,” he says. “I want to get people inspired with robotics. What Arduino did with microcontrollers, we want to do for robotics with this.”

EngiMake’s Kickstarter is now live at getquadbot.com