Elevate your design and manufacturing processes with Autodesk Fusion

With the recent re-release of Fusion 360 Ultimate, the Simulation work space saw a number of major improvements, one being the Event Simulation tech preview.

You are probably asking yourself what is Event Simulation, and how can it benefit my design process? Simply put, Event Simulation is a powerful study type that allows you to investigate multi-body interactions in your designs. Even the name, “Event Simulation,” is intended to convey the idea that you are going to simulate a process where you have lots of moving pieces. At its core, Event Simulation has a dynamic solver designed to efficiently compute the real-world motion and deformations of your model which can be large. This is a nonlinear solver at its best!

Built-in to the solver is a fully automatic contact and detection algorithm that will track and resolve all the interactions between all the individual parts in your assembled model. With a click of a button you tell Event Simulation “hey, make sure you detect all the collisions and interactions in my model.” What could be simpler than that?

Large sliding relative motions (with or without friction) are perfectly acceptable. The solver doesn’t care whether the parts start close together, or far apart; the solver automatically tracks all the parts and detects if they will hit each other.

Inherent to the concept of Event Simulation is including time in the simulation – all simulations occur over some duration for the event. Naturally, the first events that come to mind are impact simulations. These are true “dynamic” events such as a bowling ball striking pins, a bicycle helmet striking the ground, or even a bullet penetrating an armor plate. In these types of simulations, the duration would typically be measured in milliseconds or even microseconds. Event Simulation automatically picks the correct time increment size to use to integrate the motion over the event duration (supplied by you).

You will probably be surprised to learn that in order to simulate your event, the solver usually takes a very large number of very small time increments – typically thousands! The good news is that the solver is very efficient and multi-threaded, which means when you submit your Event Simulation study for solving in the cloud, it’s going to use many processors to complete the simulation as fast as possible.

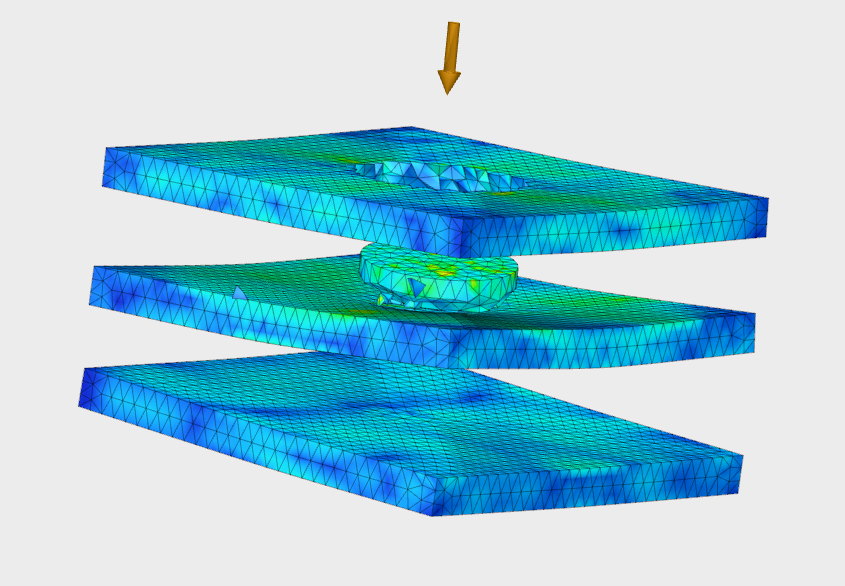

At this point you may have also asked yourself how you could simulate something seemingly complex, such as the example of a bullet penetrating an armor plate. With Event Simulation, modeling the nonlinear behavior of materials is very straightforward and the solver even understands the concept of material failure.

The solver will watch all the material in your model to see if it exceeds the failure criteria that you define for it. And if it does, we start to break things! Yes, we are going to literally tear apart the model and that powerful contact detection algorithm is going to automatically keep track of all the new surfaces that get exposed. All those bits and pieces of your model that break away and go flying off are participating in the impact event that is going on. This is the key ingredient in how we realistically model something like an ax chopping wood. And remember, all of this is automatically taking place just by clicking that single button to enable contact in your model.

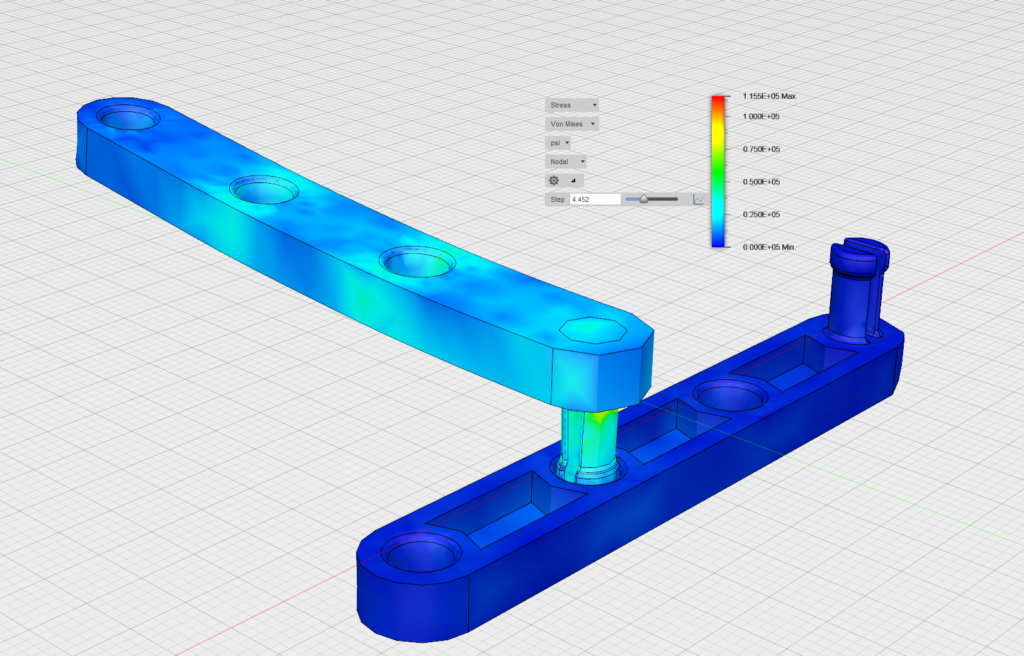

Guess what? It doesn’t stop there…you can do so much more than dynamic impact or drop events using Event Simulation. Snap-fit simulations, for example, are particularly well-suited for Event Simulation. Snap-fit processes take place over a relatively long duration (maybe a second or so), and may not seem ideal for Event Simulations due to those very small time increments sizes I mentioned.

But time is relative, and you can often model what are essentially static loads in Event Simulation by artificially speeding up the process (i.e. simulate the event in an artificially shorter duration). Of course, the trick with this approach is picking the right amount to speed up the process without over looking inertial effects. Our next post will dive into this concept a bit deeper in deciding how to pick the “right” time duration for these types of slower events.

Bottom line is this: regardless of whether you’re a seasoned simulation pro or you’ve never done a simulation before in your life, you will quickly find that Event Simulation is a tremendously powerful study type to have in your tool chest. I encourage you to check out Event Simulation and see for yourself how it can revolutionize your process of making things! We have provided a number of Event Simulation samples right inside of Fusion so you can get started right away.

To learn more about our samples, check out our forum post here.