Orange County Choppers (OCC), the focus of Discovery Channel’s long-running American Chopper, is known for its Easy Rider-style motorcycles—complete with loud V-twin gas engines. So where did this futuristic all-electric bike come from?

The design emerged from the mind of OCC designer Jason Pohl as he riffed on the concept of “fusion” as part of OCC’s collaboration with the Autodesk Fusion 360 team.

“I wanted it to stand alone, completely,” he says.

Helping a Company Founder Build a Motorcycle Empire

OCC has been making motorcycles since 1999, when company founder Paul Teutul Sr. started building custom bikes in the basement of his house. He started it for fun, but soon his unique designs attracted lots of attention. Discovery Channel took notice, and Teutul built a fabrication shop attached to his iron and steel business in upstate New York to keep up with demand.

As Pohl explains, “It kind of blew up from there.”

Pohl first encountered OCC in 2004, not long after he had graduated from art school in his native Illinois. Pohl was creating animations for a video game that featured OCC bikes. Teutul liked his work, and figured that the kind of 3D modeling used in the game could be translated into designs for real motorcycles.

Pohl’s been working for OCC ever since. Thanks to the long-running success of American Chopper and his role on the team, he’s seen a lot of the world in that time. He’s traveled as far afield as Australia and Malaysia and met many stars such as Shaquille O’Neal, Bill Murray, Russell Crowe, and baseball ace pitcher Mark Buehrle.

Jumping Into the Deep End of 3D Design

“I’m way more of an artist than I am a geek,” Pohl says, but even when he was in school he knew that he needed to learn software for the sake of his career. “I wanted to be a designer,” he says, “so I forced  myself, kicking and screaming, to learn how to use the computer to my advantage.”

myself, kicking and screaming, to learn how to use the computer to my advantage.”

Earlier this year, Pohl met a member of the Autodesk staff who encouraged him to try Fusion 360 for a design. “I was a SolidWorks guy,” he admits. “I was terrified to switch. It’s like jumping into the deep end of the pool.” Once he started using it, though, he thought “Wow, this is incredible. It is really a magic show.” In comparison to everything he had used before, it was “cleaner” and “snappier.” As he puts it, “You don’t really wait on anything—it just happens.”

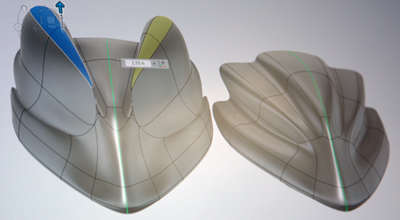

He uses the example of designing the new bike’s headlight assembly using T-splines in Fusion 360. In SolidWorks, he says, “I would probably need a solid day just to get the lofts going and the surfaces  going.” The process would have involved using three different features in SolidWorks to rotate, move, and scale the surface model, then laboriously exporting everything into Mastercam to prepare the design for manufacture.

going.” The process would have involved using three different features in SolidWorks to rotate, move, and scale the surface model, then laboriously exporting everything into Mastercam to prepare the design for manufacture.

With T-splines, by contrast, you just click and drag to alter position, shape, or size. “It’s like a digital version of clay,” Pohl says. He laughs when he adds, “except when you’re pushing it around it doesn’t leave thumbprints.”

Pohl has found that the integrated CAM is much easier in Fusion 360. “I use it every day now,” he says. “It’s a game changer for me. I just have more power to take a concept, model it up, and then take it to a CNC machine.” He and the OCC machinist have also used Fusion 360 to export DXF files for use on their water jet machine to make some of the metal parts.

His overall verdict on Fusion 360? “It just escalated my game here at Choppers.”

A Fusion Motorcycle Like No Other

It’s not like Pohl started with a simple project: The very first thing he tackled in Fusion 360 was the entire body assembly for the electric bike. He laughs at his own ambition when he adds, “I didn’t start off and make a kickstand, know what I mean?”

Wanting to create a bike that would be totally different, he lit upon the idea of making the new design a true “fusion” in every sense. Unlike the long-forked choppers OCC usually makes, this bike is an urban  “hopper”—lightweight and with lots of ground clearance. Using an electric motor allowed Pohl to eliminate the exhaust system and V-twin engine of other OCC designs, which “opened up a whole new world of possibilities.” With a slimmer drivetrain, he explains, “You have room to express yourself with more creative elements that take up the whole bike.”

“hopper”—lightweight and with lots of ground clearance. Using an electric motor allowed Pohl to eliminate the exhaust system and V-twin engine of other OCC designs, which “opened up a whole new world of possibilities.” With a slimmer drivetrain, he explains, “You have room to express yourself with more creative elements that take up the whole bike.”

In line with the “fusion” idea, the bike incorporates components inspired by other types of vehicles: the aluminum front end of a sport bike, the gas shocks of a snowmobile, and the rear sprocket of a motocross racer, along with high-durability plastic elements and a few key parts in titanium.

“It was something new, fresh for us to do,” Pohl says, adding that every part of the new design came out of Fusion 360.

Pushing the Envelope with 3D Design

Given the success of the project, Teutul wants the team to use Fusion 360 to design a new line of aftermarket parts for Harleys. Pohl describes Fusion 360 as “a new weapon in my arsenal here.” He adds, “I wish I would’ve got my hands on it sooner.”