Young entrepreneurs Bonne Wilce and Saskia Smits of a new Dutch start-up, FabCreator, bring forward their vision of next-generation CO2 Laser Cutters. Their goal is to revolutionize the CO2 laser cutting industry by producing a new range of affordable, open source systems, bringing digital fabrication tools to makers, hobbyists and professionals across the globe with their Fab40 and Fab100 products.

Young entrepreneurs Bonne Wilce and Saskia Smits of a new Dutch start-up, FabCreator, bring forward their vision of next-generation CO2 Laser Cutters. Their goal is to revolutionize the CO2 laser cutting industry by producing a new range of affordable, open source systems, bringing digital fabrication tools to makers, hobbyists and professionals across the globe with their Fab40 and Fab100 products.

Fab40 is equipped with a 40W CO2 laser for home and semi-professional use. It is fully certified and suited to cutting up to 5mm of material or engraving anything up to 80mm thick! FAB-100, a 100W CO2 laser, can cut up to 12mm of most materials. Both are fully certified and suited for quick cutting and engraving of parts.

Fab40 is equipped with a 40W CO2 laser for home and semi-professional use. It is fully certified and suited to cutting up to 5mm of material or engraving anything up to 80mm thick! FAB-100, a 100W CO2 laser, can cut up to 12mm of most materials. Both are fully certified and suited for quick cutting and engraving of parts.

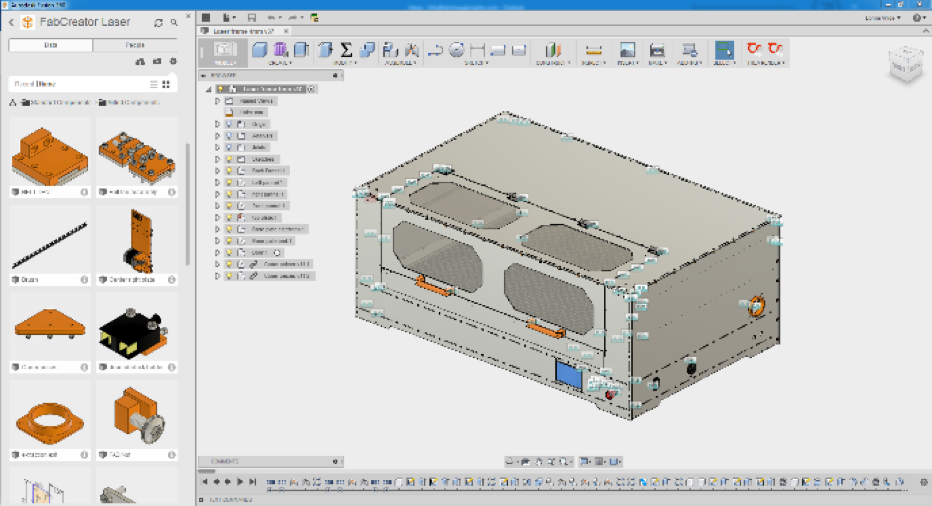

When they discovered Fusion 360, using its diverse modeling techniques and cloud-based services, they were able to take their designs to the next level.

According to Wilce: “Typically the cost of a capable CAD tool is enough to kill the project before it can even be envisioned in 3D. This is where Fusion 360 turns the industry on its head. By offering new users, students, hobbyists and start-ups this powerful CAD/CAM package for free or an affordable price, Fusion 360 is facilitating the creation of new ideas and innovations around the world. Having both been previously trained in SolidWorks, we found ourselves stuck with a skill for a product we could not afford.”

FabCreator not only used Fusion 360 to design the Fab40 and Fab100, but FabCreator runs on the open source electronics (i.e. Smoothieboard) which is already supported directly by Fusion 360. FabCreator has already created simple workflows with Fusion 360 support for laser cutting tools. Users can design their product in Fusion 360, select the contours of the design in the laser CAM tool and generate toolpaths for the Fab40 and Fab100 laser cutter. FabCreator also hopes to develop the laser CAM module to allow for more complex designs and usability, which should be great news for product designers and engineers familiar with CAD design as now they will be able to design and fabricate all in one program.

To complement their design workflow, FabCreator utilizes Solid Iris Technologies’ exporter plugin called Thea for Fusion 360 (which is available for download on the Autodesk App Store) to enhance their product visualization workflow. The exporter plug-in allows Fusion 360 users to visualize their projects using Thea Render, which is a physically based biased/unbiased renderer that can combine both CPU and GPU performance for accelerated 3D rendering (requires NVIDIA CUDA GPU).

“Using Thea for Fusion 360, we were able to export our complex designs into the Thea Render Studio with great ease and create stunning visual results in a very short timeframe, using the robust range of physically based material libraries. Thea for Fusion 360 also allows the incremental push of Fusion 360 designs to Thea Render Studio, giving us the opportunity to close and restart projects dynamically, which is a great help. TheaRender, overall, has great features that let us give an impression of scale and the working environment of our products.” says Bonne.

FabCreator has plans to launch their project on Kickstarter in early May, which they hope will secure their initial funding required to set up production and ‘kick-start’ their business. As an open source project, their goal is to connect with the community and bring forward their vision of affordable, revolutionary CO2 laser cutters. Stay up-to-date with FabCreator and their Kickstarter launch in May 2016 by liking their Facebook page and following them on Twitter. They also invite you to join them at the Maker Fair Paris April 30th-May 1st and at the Hannover Maker Faire May 27th-29th where they will be showing off their impressive designs and you can catch up and share thoughts on designing products with Fusion 360 and Thea Render.

FabCreator has plans to launch their project on Kickstarter in early May, which they hope will secure their initial funding required to set up production and ‘kick-start’ their business. As an open source project, their goal is to connect with the community and bring forward their vision of affordable, revolutionary CO2 laser cutters. Stay up-to-date with FabCreator and their Kickstarter launch in May 2016 by liking their Facebook page and following them on Twitter. They also invite you to join them at the Maker Fair Paris April 30th-May 1st and at the Hannover Maker Faire May 27th-29th where they will be showing off their impressive designs and you can catch up and share thoughts on designing products with Fusion 360 and Thea Render.