DIAMOND SCHMITT ARCHITECTS

At KING Toronto, a new urban landscape comes to life with BIM

THE NEW POSSIBLE

Share this story

Reimagining city living to foster nature, sustainability, and community

Diamond Schmitt Architects (DSA) is using BIM (Building Information Modeling) to achieve the ambitious vision for KING Toronto, a multi-use urban development designed to foster community well-being. Draped with lush gardens, the terraced design maximizes light, air, and views. DSA is helping to reimagine what city living can be—and by prioritizing sustainability from the start, they’re optimizing design decisions to deliver a result that’s good for the planet, for people, and for business.

KING Toronto’s undulating shape was designed to embrace biodiversity, maximize views, and allow light to reach the neighboring street all year round.

A vision for a more livable urban environment

In the heart of King Street West, a downtown Toronto neighborhood that’s quickly emerging as a vibrant creative community, a team of architects and developers is creating a new model for city living. The KING Toronto development breaks the mold of the standard high-rise tower: Its 16 stories emerge from a set of heritage red brick buildings, with condominium units stacked like pixels to form a landscape of peaks and valleys.

Combining retail shops, offices, and over 400 residences, KING Toronto features twining vines and gardens spilling from terraces, balconies, and green roofs. Glass bricks add lightness and luminosity to the building’s facade. At the center, a public plaza connects the community and serves as a hub for a network of neighborhood walkways.

Architecture that nurtures community

-

![Rendering of the penthouse levels of KING Toronto shows the building’s green roofs and gardens with a waterfront view]()

KING Toronto’s pixelated form was inspired by Habitat 67, an iconic model community built from prefab concrete units for the 1967 Montreal World’s Fair.

-

![Rendering of KING Toronto at night shows the angled shapes of the residential units rising from street level to mountain-like peaks]()

Instead of being set square to the city block, the units are rotated at 45-degree angles to increase light exposure and air flow.

-

![Rendering of the public plaza at KING Toronto shows a garden at the center and vine-covered glass brick facades rising above it]()

Trees, gardens, and climbing vines integrate nature into the urban environment and a public plaza serves as the center of the community.

Related products

-

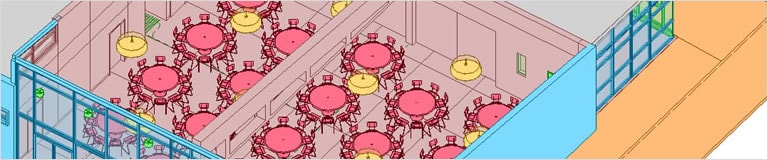

Plan, design, construct, and manage buildings with powerful tools for Building Information Modeling.

-

BIM 360 is a construction management platform that connects, organizes, and optimizes projects from design to construction.

-

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

Learn more

Think it. Design it. Build it.

Innovators like the KING Toronto team are partnering with Autodesk to reimagine what’s possible. Discover how companies across design and make industries are taking the problems of today and turning them into something amazing.