DESIGN & MANUFACTURING

Product Data Management

Get your data under control in one centralized system

DESIGN & MANUFACTURING

Get your data under control in one centralized system

Product data management centralizes design data and engineering processes in one location, saving time and effort for all involved in the product lifecycle. You can quickly find and reuse files, track revisions, collaborate, and share product data beyond engineering to improve downstream processes and workflows.

Ensure people are working with the most up to date information in a system that automatically tracks changes, maintains past file versions, and captures the entire history of designs and product data.

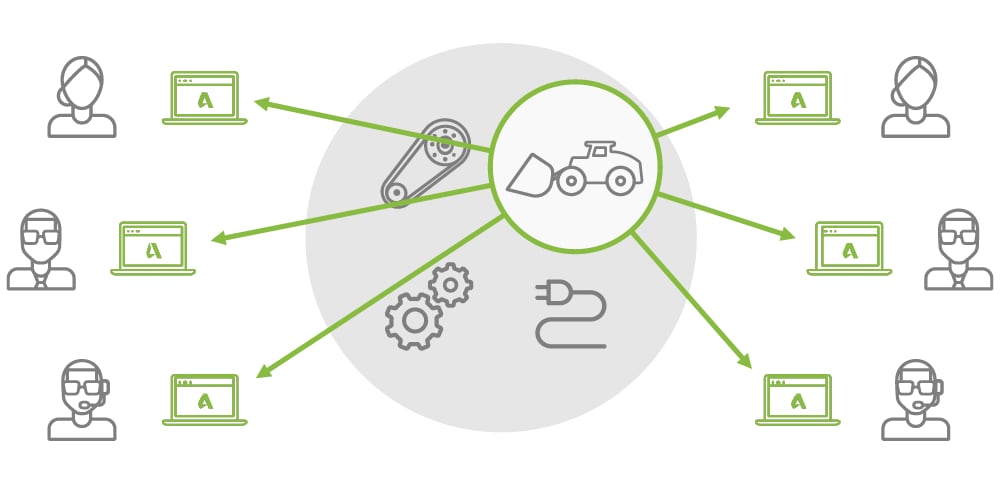

Centralized product data is available within and beyond engineering, which eliminates bottlenecks and improves product lifecycle processes. You can manage all file types and any information related to a product with PDM, including documents, spreadsheets, images, PDFs, CAD data, and associated metadata.

Work without interruption with seamless integration between your Autodesk design tools and product data management. Product data in a single system allows cross-functional teams to design concurrently without overwriting files as opposed to sharing product information through email, spreadsheets, and other isolated, manual methods that lead to lost data.

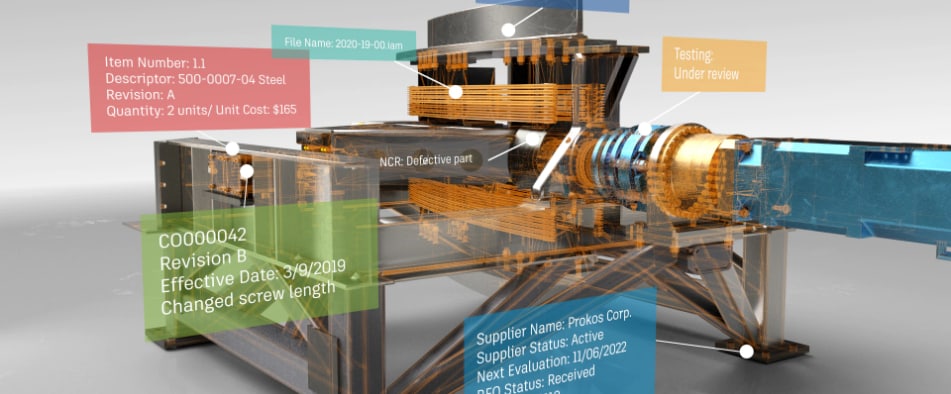

Create an engineering BOM derived from CAD design data to effectively track and communicate across departments the details of how a product was functionally designed.

Connect engineering BOMs with other departments and business systems for greater efficiencies and to avoid manual entries which can lead to errors, poor quality, and delays.

Provide CAD administrators with customizable tools to help enforce organizational standards on data creation, review, and release processes, as well as industry standards like ISO 9000 and RoHS.

In this on-demand webinar, we'll cover NPI workflows that speed up time to market, automated change request (ECR) and change order (ECO) processes, item and Bill of Materials management to reduce errors and improve collaboration, preventing and responding quickly to quality issues, and staying connected 24/7 to your global supply chain.

The Difference Between PDM & PLM and Why You Need Both.

Improve quality, reduce costs, and get your products out to market faster. Realize the benefits of using product lifecycle management with data management.