说明

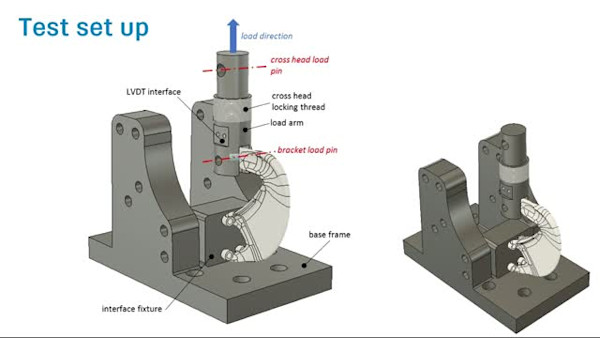

Are you an industrial designer (or a CAD user in general)? Are you not doing much with the simulation tools? Come and learn why and how you should be exploiting finite element analysis (FEA) and simulation in Fusion 360 software. Engineers are designers’ teammates, not opponents. Design and validation tools will help you collaborate with engineers more effectively. Those tools will also help you to carry a design to production with fewer changes. You’ll go to engineering with a sound concept, rather than something that needs a lot of help. We will talk about static stress, shape optimization, and maybe even a little generative design.

主要学习内容

- Test designs in Fusion 360 with static stress and shape optimization, and perhaps do a little generative design as well

- Learn how to apply simulation tools to your design process

- Learn how to export simulation reports for engineering

- Discover Fusion 360 Simulation tools

标记

产品 | |

行业 | |

主题 |

喜欢这门课的人也喜欢