Steve Donohoe is a freelance steelwork and cladding designer based in North East Scotland. His company specialises in design & detailing of structural steelwork, architectural steelwork and cladding for the commercial, agricultural, domestic and Oil & Gas industries.

Steve recently used Advance Steel to model new railings for a renovation project, and took some time out of his busy schedule to speak with us.

Q. How did you ensure that the exact site dimensions were taken into consideration for your renovation project?

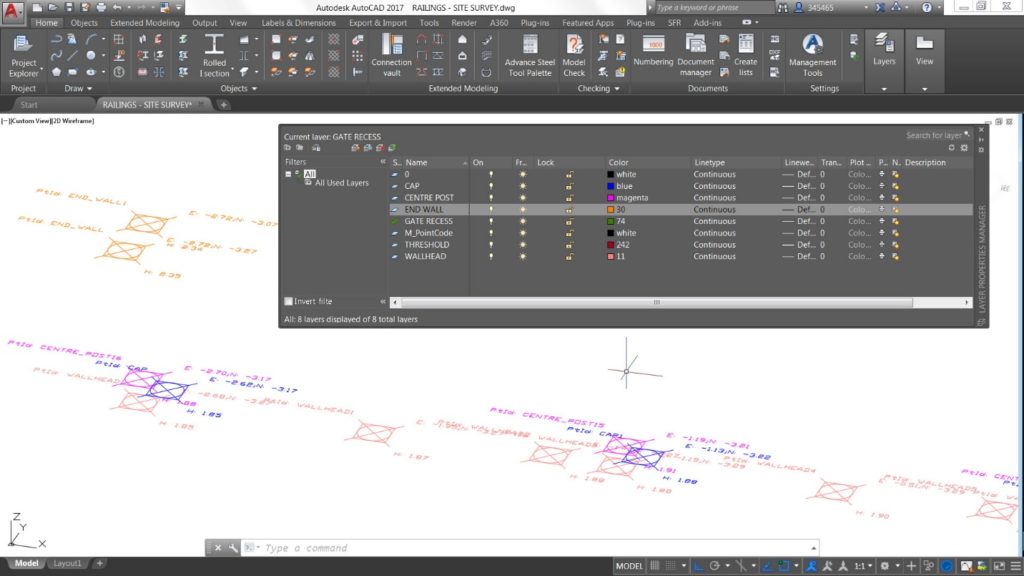

Site surveys are often tricky, especially for old structures that are not often square / level / plumb. For this survey, I used a Total Station in reflectorless EDM mode, and with this I was able shoot the exact position of all relevant existing posts, openings and walls. This survey data was then exported in DXF format as a series on reference points. Using these points, I was able to build a 3D model of the existing structure in Advance Steel.

Q. Why did you use Advance Steel to build the 3D model of the new railings?

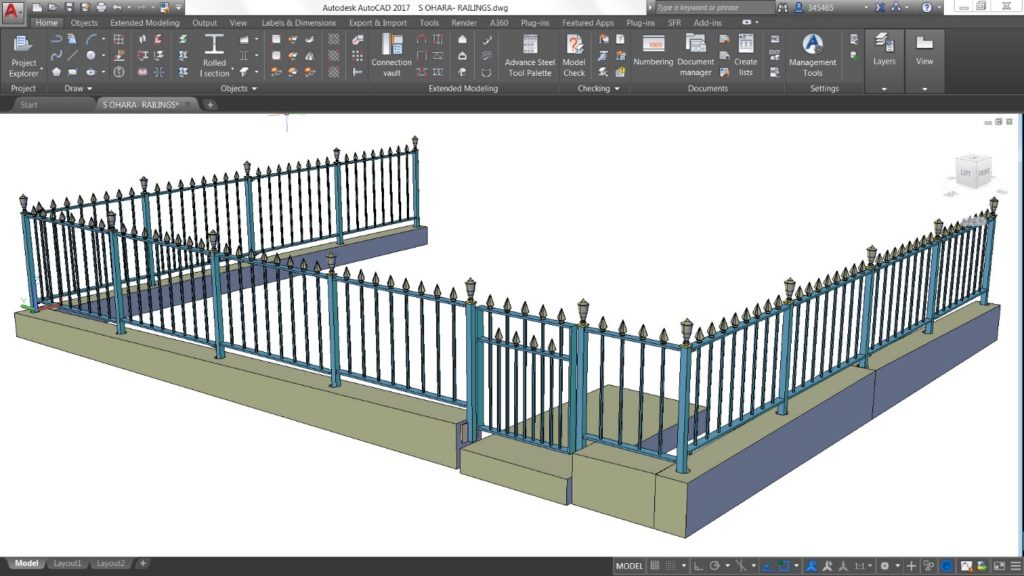

As a freelance designer, I need software that can adapt to any type of project and I have found Advance Steel an extremely versatile tool. The projects I work on range from agricultural buildings to stairs, ramps, lifting beams, walkways and even steelwork for offshore oil and gas. The Advance Steel macros are very powerful and can assist in modeling all types of projects quickly and accurately. A good example would be the stair & railing macros. With these you can easily model almost any type of stair & railing, and you can even save these to your library for use in future projects which can be a great timesaver.

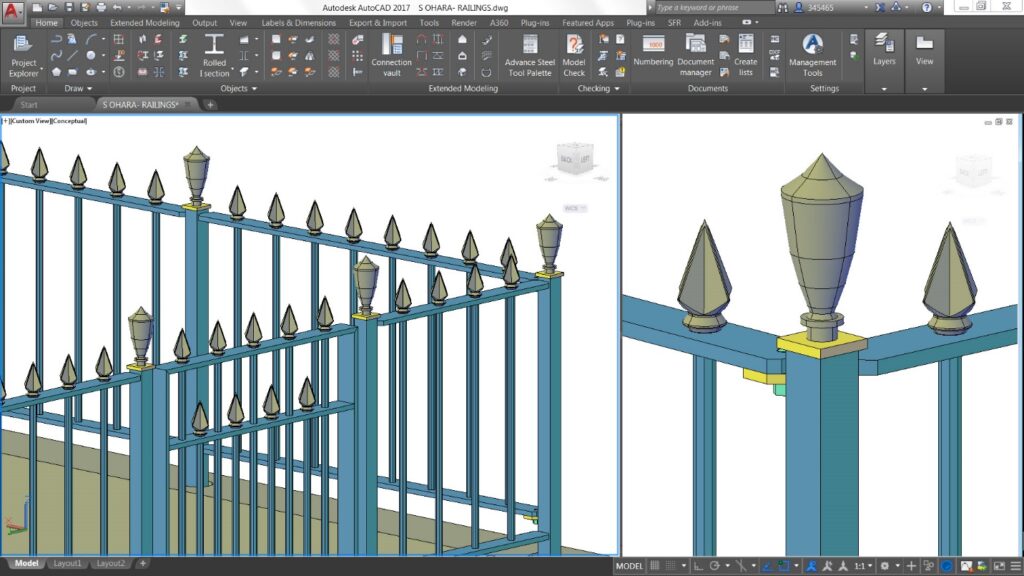

For these railings I chose not use the macro, instead I modeled the posts to suit my survey and then drew an AutoCAD line between these. I then used the AutoCAD ‘divide’ command on this line to split it into equal segments and this gave me a reference point to insert each baluster and railtop. I really like the way Advance Steel does not tie you into a specific way of working and you can mix and match AutoCAD commands to suit how you want to do the job.

Q: Were you able to easily insert 3D BIM objects from product libraries?

For the urns and railtops the supplier was not able to provide 3D DWG files, but I was easily able to model these using traditional AutoCAD tools. These were then inserted into Advance Steel as a ‘special part’. Advance Steel treats these like any other object and will pull them through to all fabrication drawings and include them in BOM’s. I have found this a very useful tool especially for architectural metalwork projects, when a similar workflow can be used to add glass clamps, brackets, special balusters and the like.

Q. Would you recommend a model-based delivery project to help meet expectations for delivering fabrication drawings and other assets?

Most fabricators are familiar with intelligent 3D models as they have been using these for many years for buildings, although many have not yet adapted the same approach for architectural metalwork such as stairs & handrails. These items are often made by a skilled fabricator, who has the experience to work out exactly where everything should be and how it should join together, coupled with a full trial assembly in the workshop.

Feedback from my customers has been very good so far and some have even have been able to cut out the trial assembly altogether for stairs & handrails. Others have commented that having a full set of fabrication drawings allows them to put their less experienced fabricators onto the job and still be sure that it will fit correctly.

Nice work, Steve!

If you’d like to share your structural design, detailing, or fabrication project on BIM and Beam, please contact us and tell us about your project or tweet a photo directly to our account @AdvanceSteel or use the hashtag #AdvanceSteel.

For more from our customers on using Advance Steel check out these customer stories below:

- Coastal Library Rides the BIM Wave

- ‘Unbelievable Speed’: Fabricator Slashes Time with Autodesk Advance Steel Detailing Software

Learn more here about the features in Advance Steel’s latest release.