Building Information Modeling (BIM) is a critical part of how structural systems are designed and built today, but the reinforced concrete industry has been lagging behind structural steel when it comes to its adoption of BIM. This is due to the highly fragmented nature of its supply chain which requires a number of different designers and suppliers to collaborate and simultaneously deliver the final product. Nowhere is this more apparent than in our conversations with Autodesk users. In fact, when we ask our users what they want to see in a BIM-centric solution for concrete, we often hear a variety of answers that differ drastically depending on someone’s role on a project.

- Engineers & Designers: Gain more engineering insight while creating the design-intent of structures, and seamlessly coordinating with assistance of analysis and local building code requirements.

- Fabricators: Maximize production and delivery efficiency while minimizing time spent on detailing and coordination with the field.

- Contractors: Optimize planning and estimation tasks by getting access to accurate quantities in the early stages of a project, thereby optimizing the installation process to avoid rebar clashes on site and coordination with other trades.

Despite the difference in opinion on the BIM solutions needed for reinforced concrete, it’s clear that the industry is ripe for radical disruption. Over the last several years at Autodesk, we’ve made a commitment to address the opportunities our users are asking for by investing in customer-centric solutions for the reinforced concrete industry that better connect concrete design and detailing to fabrication.

Revit for Reinforced Concrete

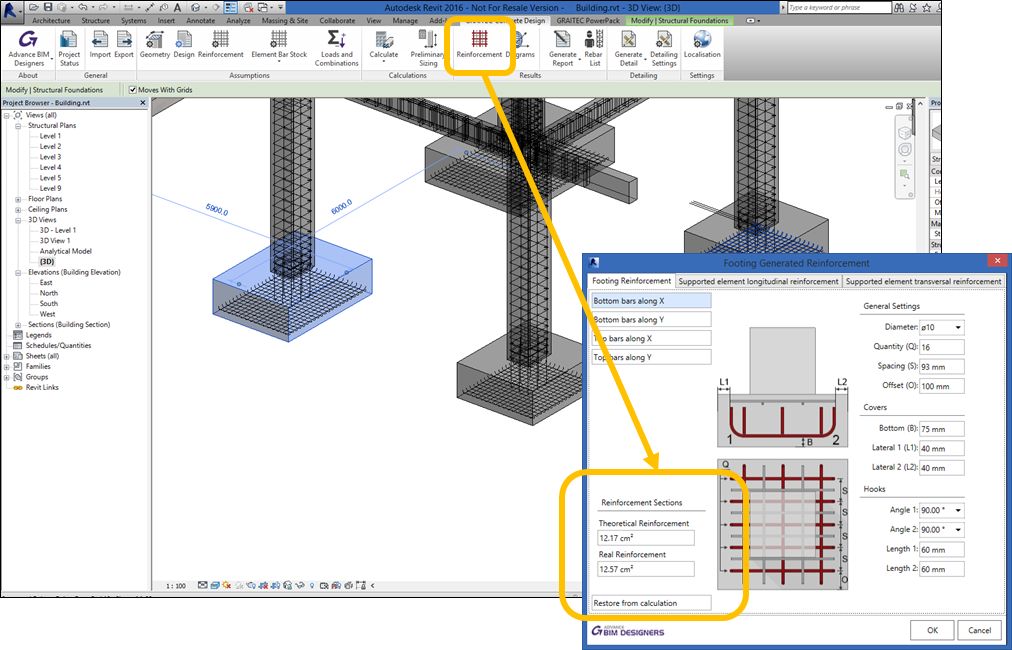

Our BIM strategy for reinforced concrete is centered around making steel reinforcement detailing very integrated with both the structural design and detailing process. Not only does this approach result in creating relevant, more accurate and up to date documentation, it also drives end-to-end workflows in a “connected,” fully paperless way. To this end, we’ve been making Autodesk Revit a robust, customizable, model authoring platform that supports BIM workflows for any discipline or trade—including those designing and detailing reinforced concrete. Our investments in Revit have also focused on respecting the various Levels of Development (LOD) that must be supported in parallel throughout the project lifecycle.

For more on the capabilities of Revit for concrete, check out some of our past BIM and Beam blog posts:

- Reinforcement Connectors in Revit 2017

- Bent Fabric Sheets in Revit 2017

- Variable Rebar Distribution in Revit 2017

- Rebar Constraints Management in Revit 2017

Leveraging technology partners to create a collaborative BIM ecosystem

A key part of our strategy for reinforced concrete has been to partner with technology partners who have a proven track record in delivering highly localized rebar design-to-detailing solutions to customers in the concrete industry using traditional 2D CAD platforms. Autodesk is proud to be partnering with our industry partner SOFiSTiK and solution associate partners Graitec and aSa who bring Revit based tools that address local standard requirements, process automation, advanced productivity requirements, and make Revit the best suited BIM authoring solution for reinforced concrete rebar detailing. As the AEC industry adopts BIM, these partners are rebuilding on Revit so they can provide their customers and future reinforced concrete partners a more collaborative BIM environment.

Together with Autodesk we have developed and are still working on a Revit integrated workflow for designers. This workflow covers all design aspects such as formwork drafting, analysis and code checks of structural members plus reinforcement generation and detailing all in Revit. This rebar information can be exported to bending lists or directly transferred to bending machines for fabrication purposes. By using Autodesk Revit and the SOFiSTiK BIM applications it is for the first time possible to provide a fully BIM integrated workflow for construction engineering.”

–Frank Deinzer, Managing Director SOFiSTiK AG

“It is no surprise that the concrete industry is decades behind its steel counterpart when it comes to BIM. Favoring 2D systems for documenting and detailing reinforced concrete has enabled the industry to overcome shortfalls in modelling software’s ability to meet varying country standards, complex rebar configurations and manage the sheer volume of steel in each project.

But all of that is changing. Thanks to the global adoption of BIM, advances in software technology and countless lessons learnt, the concrete industry is benefitting from an acute focus by software vendors like Autodesk and GRAITEC that is rapidly decreasing the BIM gap. Concrete, it would seem, is poised even to overtake its steel rival.”

–Carl Spalding, former GRAITEC Product Strategy Director

The benefits of Revit for reinforced concrete

So you might be asking, what benefit does using this Revit-based strategy provide? What value does it provide our users? We see BIM-centric concrete solutions helping our users in four main ways:

- Combines the versatility of 2D documentation with the higher level of fidelity and accuracy of 3D modeling of steel reinforcement and concrete accessories, with minimal effort to produce both.

- Allows Autodesk users to design and detail with clash prevention in mind to reduce clashes both in the preconstruction and site execution project phases.

- Enables the transition from design to detailed models while respecting both perspectives, following local code requirements, and automating the process of making changes so they are less disruptive to the design process.

- Increases transparency and quality of the model information being used from bidding to procurement by not only providing quantifiable information, but also enabling access to it in collaboration friendly environments.

These benefits are also supported by Revit’s flexible work sharing and cloud collaboration solutions that allow more project stakeholders to connect to the BIM process.

What’s next?

So this all sounds compelling but if you have an engineer or detailer mindset like me, you want to see real world examples and proof. Who is really using Revit to create 3D rebar models that generate the required rebar shop deliverables on real projects?

Get a sneak peak of who is using Revit by checking out the technology partner pages for Graitec, aSa, and SOFiSTiK, viewing our line up at Autodesk University this year, or reading this use case by VK Engineers.