Q. What is the name of your firm and where is it located?

VLE Draughting (Pty) Ltd. – “VLE” stands for Visual Language of Engineering.

We are located in Pretoria, South Africa.

Q. How many employees does your firm have?

VLE Draughting is still a young company, consisting of two owners, each with a diverse set of knowledge and skills.

Wayne Page (that’s me) is our Senior Detailer, his main responsibility is the actual projects; modeling and detailing from start to finish. He keeps in touch with all stakeholders during the manufacturing and construction process. He controls and communicates any additional information where needed and conducts site visits and meetings.

Benandi Page is currently responsible for managing project progress, office, advertising, marketing, administration tasks and financials. During an increase of projects or tight deadlines, Benandi will assist with the detailing.

Q. What kind of projects does your firm specialise in?

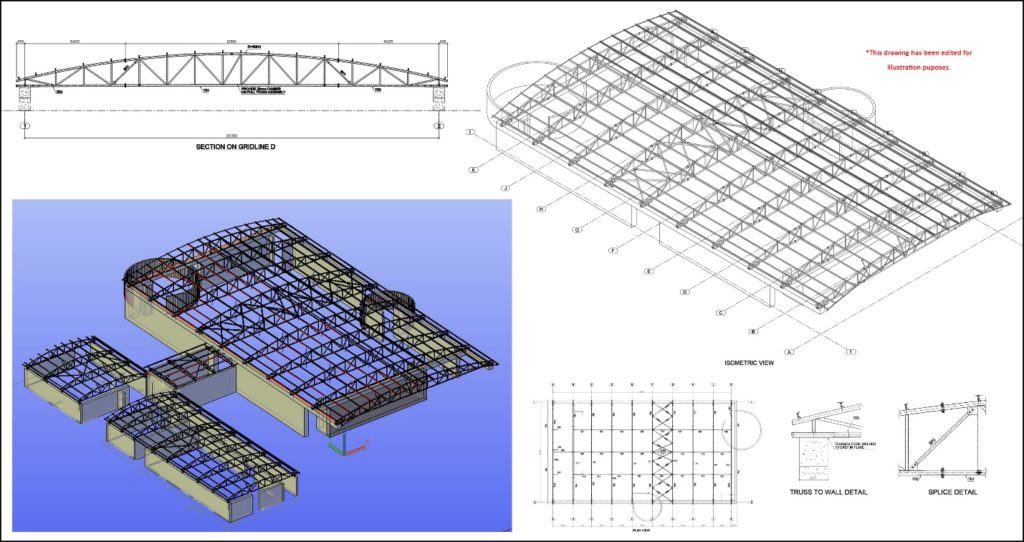

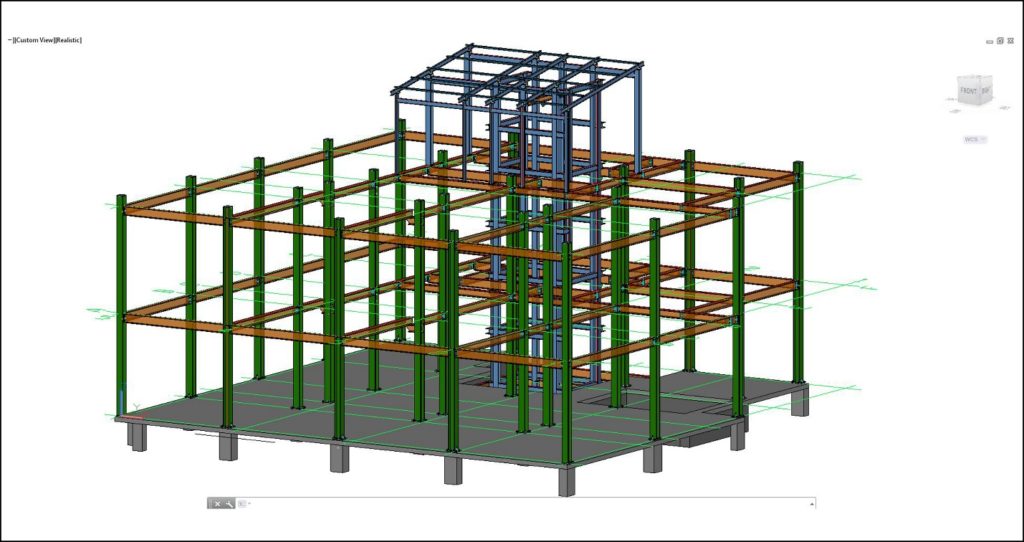

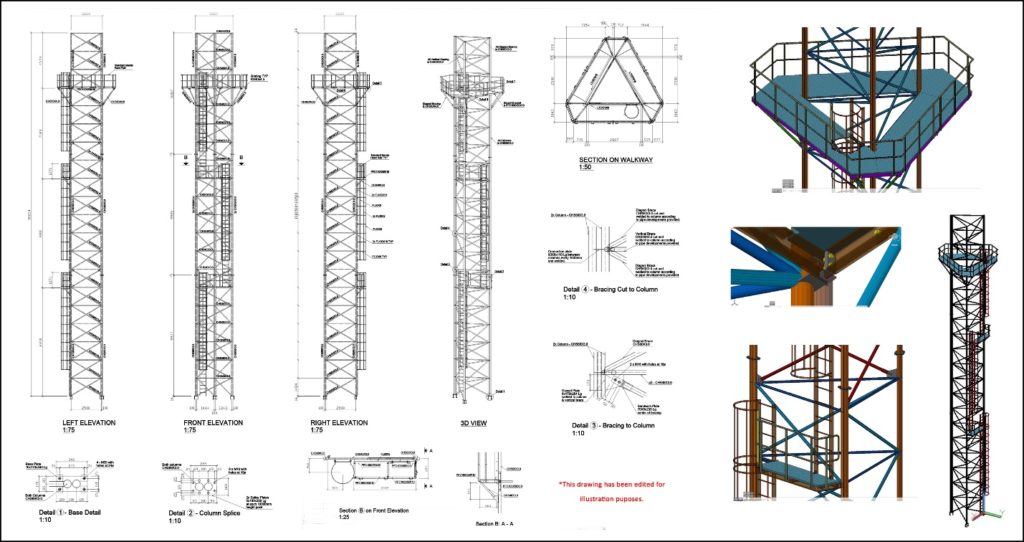

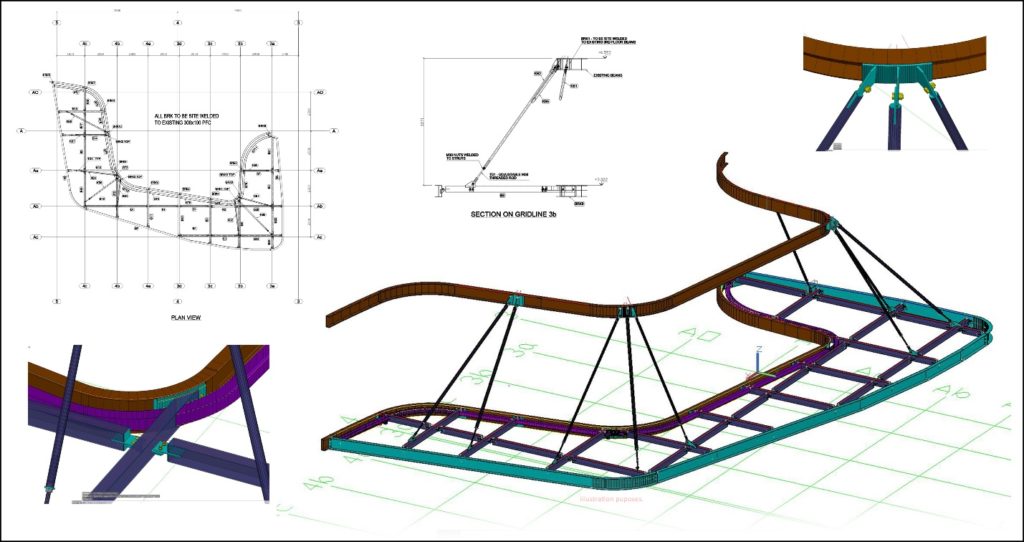

Structural Steelwork ranging from large roof structures, buildings, platforms, towers etc. Here are a few different types of projects we’ve done:

Curved Pipe Truss for the Sokhulumi Community Centre. This was our first project after we have completed our Advance Steel training. Although the project was a challenge, we could already see major benefits working on the Advance Steel software. The entire building consisted of four structural roofs.

Building Extension (Mooi Street Structure)

Platform (Festive Cold Room – New Mezzanine Floor). Site visits for this project were a big challenge, as the cold room is -22˚ Celsius!

Tower (BH Supporting Tower Structure). This was the first project where we collaborated between Advance Steel and Autodesk Revit. The engineer sent us the Revit model and we imported it into Advance Steel. We simply had to create connections and the cat-ladder. We were also responsible for providing the tender and workshop drawings at the end. Autodesk ensured collaboration and interoperability between their software packages time saving, fewer errors and no rework. These were the top 3 benefits of using the BIM (Building Information Modeling) process.

Curved Canopy. This was one of our most challenging projects. The canopy had to tie in on existing curved members of a building; there was just no room for error!!

Q. How long have you been using Autodesk Advance Steel?

For about two years, since the beginning of 2015. We started on AutoCAD, later moved over to AutoCAD Structural Detailing, (known as ASD). Then, early 2015, our software reseller, introduced us to Advance Steel, and we knew this was going to be one powerful software package.

Q. Why did you choose Advance Steel over other 3D modeling options?

There is just no doubt, the 3D modeling process and the production of drawings is much more efficient. There are more possibilities, (options) overall available within Advance Steel. Advance Steel is customisable; if you are unable to find a connection that works, you can create a custom one, if you need an “out of the ordinary” object, then you are able to create that special part. The main factor that made us choose Autodesk Advance Steel – NO LIMITATIONS – for us!

Q. How long did it take you to get up to speed on the program?

About 2 weeks. We have sufficient experience on AutoCAD, which meant the learning curve for Advance Steel was not that steep. After completion of our training, our focus was on completing a small project, implementing the skills learnt during the course. As projects evolved in size and complicity, or when we came across certain obstacles, we were determined to find a solution. We did some in-house research and most of the time, phoned our reseller here in South Africa for support.

Q. How long did it take you to see a return on your investment after making your purchase?

After only 1 month we could see a huge improvement regarding time savings. Saving so much time per project meant that we were able to take on more projects at the same time and this increased our ROI almost immediately. The trap that people need to look out for is that KNOWLEDGE IS POWER. If you do not get the correct and sufficient training and support, you will not be able to use the software to its fullest capability. After experiencing the Autodesk collaboration and interoperability between their software packages, we saw another increase in our ROI due to less rework, less errors and we saved even more time per project.

Q. What are the key benefits you have found from using Advance Steel?

It is much faster to deliver efficient drawings which leads to saving time and reaching tight deadlines. Minimising errors, not only in 3D modeling, but also for manufacturing and construction at the end of the day. Collaboration with Revit, Fabtrol, StruMIS and Navisworks, increases our services that we provide, leading to opportunities with bigger clients for bigger projects.

Q. What is your favorite Advance Steel feature?

There cannot be just one … it is everything surrounding 3D modeling. But, I do have 2 favorites that stand out from the rest:

- To be able to copy connections, even on members’ properties that are different

- Copying an entire assembly to a new location without duplicating members

Q. What project(s) are you using the product on now?

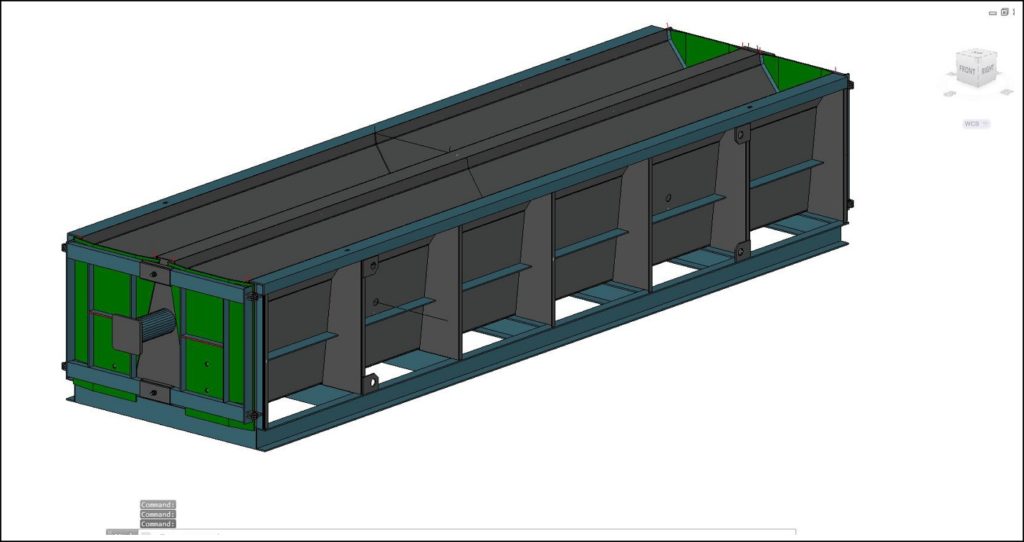

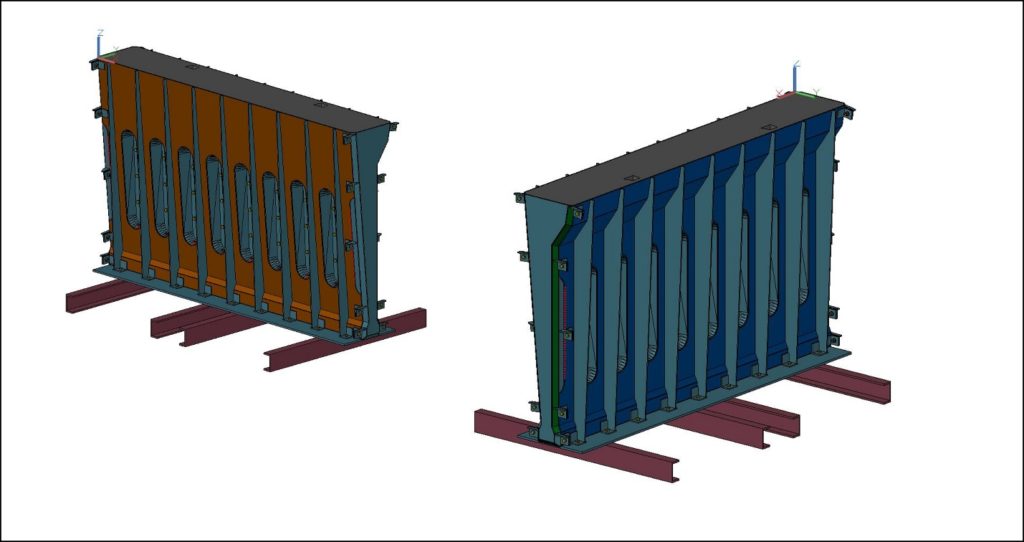

We’ve recently been involved in the design and re-creation of various concrete moulds, mostly consisting of plate work. Our client’s requirements was to use an existing 3D solid, representing the concrete shape, and to design the outer steel work in order to form the mould. The mould should be able to de-assemble in a curtain way for the concrete to be released. These projects were a new level of challenge for us… But with Advance Steel’s intelligent plate tools we were able to overcome many obstacles. Due to confidentiality, our client allowed screen shots to be illustrated, but no drawings.

Q. Do you have any advice for someone getting started using Advance Steel?

Take the time to get the correct training and make sure you have support available. Practice your skills as soon as possible, start with a small project. If you have some spare time, play around in Advance Steel to find different ways to achieve your goals. Watch YouTube videos, this is of great help. Get connected with Advance Steel forums.

Q. Is your firm using any other Autodesk products?

We are using Navisworks Freedom to export and view models, mainly for client meeting purposes. We also encourage our clients to download Navisworks Freedom – this way they get a chance to see how powerful Autodesk products are.

Thank you for sharing your experience, VLE Draughting! For more Advance Steel customer success stories, check out these recent blog posts:

- Customer Q&A: Garden railings come to life with Autodesk Advance Steel

- Coastal Library ‘Rides the BIM Wave’ with Revit and Advance Steel workflows

- Unbelievable Speed: Fabricator slashes time with Autodesk Advance Steel detailing software

If you’d like to share your Advance Steel customer success story or a recent structural design, detailing, or fabrication project that used another Autodesk product on BIM and Beam, please contact us and tell us about your project. You can also tweet a photo directly to our account @AdvanceSteel or use the hashtag #AdvanceSteel.