BIM process helped save 60 days and 10 million Yuan

CCCC Second Harbor Consultants Co., Ltd. is managing the construction phase of the project in Zhuhai, China. The project includes:

- 7 container berths, capable of berthing all kinds of 1000 DWT – 150,000DWT container vessels

- Shoreline length: 1826m, land width: 460m, total area: 736,000 m2

- Throughput capacity: 20 million ton

The total project investment is approximately CNY 4 billion Yuan.

This project is listed as one of the Ministry of Transport’s construction standardization demonstrative projects of the port & waterway project and demonstrative projects of application of BIM technology in port & waterway project. The imperfection of related BIM standards, codes and guidelines in the implementation process is the major obstacle to the smooth operation of the project. Based on Autodesk BIM platform, the formulation of related BIM standards, codes and guidelines are carried out, providing important basis and support for the formulation of the relevant standards of BIM for Chinese port & waterway project, pointing out the direction of BIM application in Chinese port & waterway project, being of great significance of the promotion of BIM technology in Chinese port & waterway project.

Unique considerations

Because the north side is connected to the Phase I project which has been put into operation, the location of the project is very special. So the design, construction and operation of the project exert great impact on the phase I project, and severe economic losses will be brought out with improper treatment measures. Therefore, how to achieve smooth transition with phase I project in the whole process including planning, design, construction and management to minimize the negative impact to the phase I project is the key problem of this project that must be taken into careful consideration;

A 1000 – ton fisheries service terminal is in the south of the project and the tonnage is much smaller compared to our project (100,000t), so there are conflicts of interest in the design, construction and operation stages. So demonstrating the design scheme of the project actually and sufficiently, simulating the construction process, coordinating interests of each stakeholder, providing decision support for interest coordination among multiple stakeholders, minimizing the negative impact, alleviating social conflict are great challenges of the project.

Benefits of BIM in the workflow

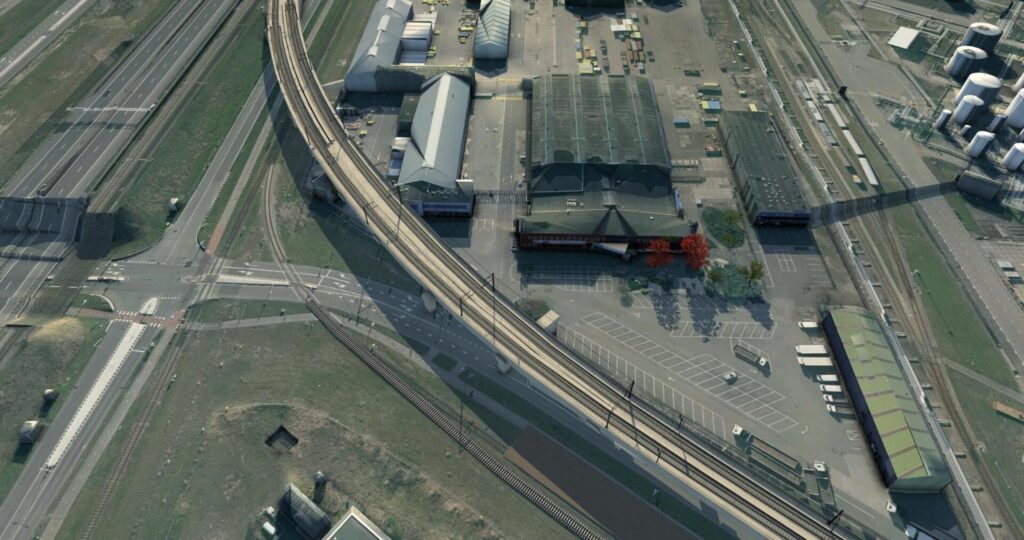

In the design stage of the project, the current model of the project is obtained through the method of oblique photography technology combined with conventional measuring method. On this basis, being targeted to focus on well making integration and cohesion for the design of civil structure, water supply and drainage, power supply, communications and fire control, etc. of Phase II dredging works, marine structure works and road & yard works to ensure the feasibility of the design scheme, improve the design efficiency and reduce the design cost.

In the construction phase of the project, the virtual simulation technology is adopted to intuitively find out the possible influence to phase I port, and to set warning isolation mechanism and contingency measures specifically, in order to minimally mitigate the influence of Phase II project construction to the operation of Phase I terminal project and to protect the interests of the owner to the maximum extent.

After the project is completed, the efficient operation could be realized through making accurate logistics simulation, integration of port machinery, road, yard resources, etc.

https://www.youtube.com/watch?v=6g1cyT0xGRQ&feature=youtu.be

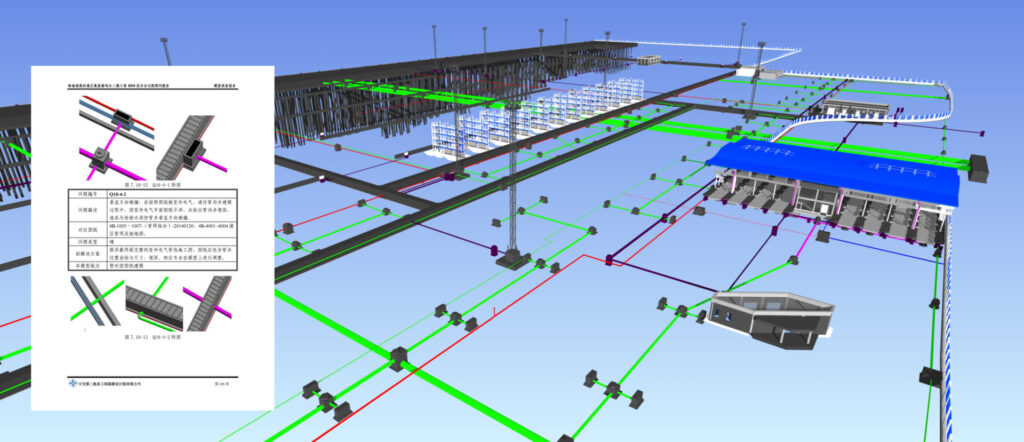

The project is different from general construction projects, for it is involved with many specialties, including dredging, marine structure, road and yard, architecture, civil structure, electric, water supply and drainage, HVAC and so on. To avoid the conflict between each specialty, BIM technology is used to review the detail design results according to detail design work process, to find out 109 problems of the “error, lack, clash” (underground pipe network problem accounts for more than 60%). It significantly reduces rework and waste of resources, saves investment and project time limit, and improves the project quality obviously.

Integrated analysis

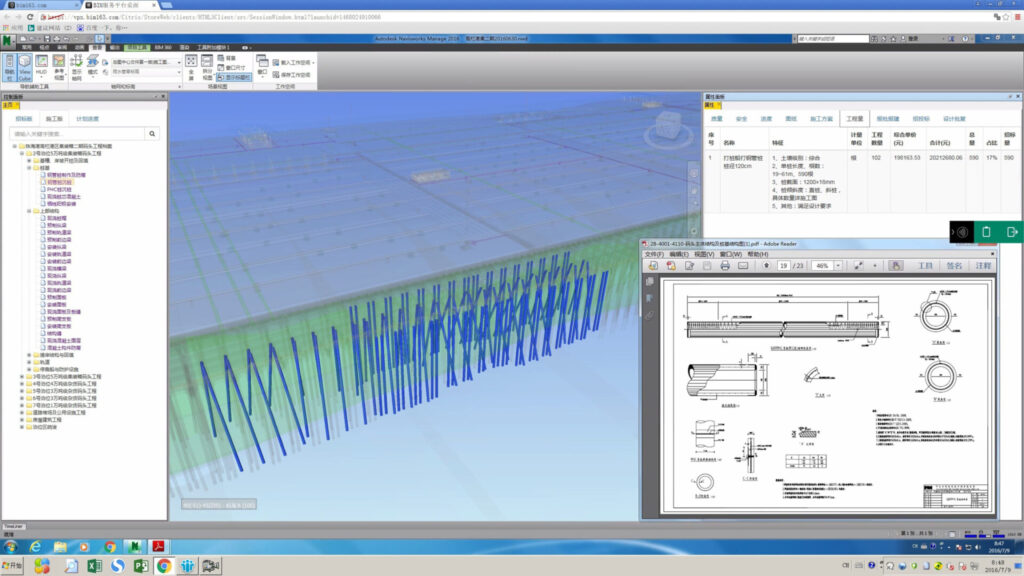

The 81-126 bent of the terminal project is about 340m in length, containing five structure sections and the buried depth of strata is relatively shallow, being embedded in weathered rock about 5m in depth, so the part of the project is underwater concealed work, the unit price is higher. To integrate the terminal structure established by Xidi series BIM auxiliary tools and 3D geological model, assist design party to make precise optimization for rock-socketed length of each pile’s embedded core column in model optimization stage and make final hole depth decision in construction stage, providing strong support to the item in settlement stage;

For the dense layout characteristics of pile foundation of the piled wharf and limited space for piling ship construction, simulations of prefabricates lifting, pile driving, rock-socketed pile and pile cap nodes construction are performed based on BIM model for construction. Through computer simulation functions, combined with the construction ships, construction equipment, surrounding environment, intuitive and quick analysis of pile order optimization and piling ship construction layout is carried out to ensure that each pile could be constructed smoothly and no collision to the finished pile in construction process.

Based on BIM model, it is proposed to make actual calculation for the quantities such as terminal and the monomer structure, the dredging and excavation site, land formation, site pavement, and compare with the statistics of the detail design outcome documents, compare the differences and find the reason, put forward the optimization space, and provide the inspection report.

Construction simulation

Based on BIM model, special construction plans are simulated, the actual construction process is implemented by virtual simulation in computer software, finding out the actual or possible problems existing in the construction, providing participants with a controlled, non-destructive, low cost, little risk and repeated method.

A 1000 – ton fisheries service terminal is in the south of the project and the tonnage is much smaller compared to the current project (100,000t), so there are conflicts of interest in the design, construction and operation stages. During the design phase, project influence analysis could be carried out based on 3D visualization presentation of project design and construction by making integration of BIM models from two different design institutes, providing decision support for interest coordination among multiple stakeholders.

Benefits of the cloud

A BIM shared cloud platform is implemented based on cloud technology to realize the centralized storage management of massive documents and the digital assets (models, drawings, video, audio), providing technical support for various project participants to query important information and files across regions, platforms and in all-weather conditions, eliminating isolated information island, realizing full share and maximum utilization of resources, improving the work efficiency greatly.

Results

The team saved 60 days and 10 million Yuan. In addition, they improved project performance and delivery in the following ways:

Improvements in project performance

The project management platform customized and developed for this project met the business control requirements from the owner (manage the project participants in the design optimization, the project investment control, construction simulation and monitoring, quality and safety supervision, quantity statistics, materials management, data management, etc.)

Improvement in project delivery

After the manufacture of completion model, it is proposed to transfer the completion BIM model and related data to the Owner’s management system, which is convenient for the Owner to carry out maintenance and operation of the later period:

- Based on the as-built BIM model, it is necessary to add the information including maintenance plan, inspection reports, work list, equipment parameters, fault time, etc. required by the project operation and maintenance period to the model, to realize the integration of operation & maintenance management system with BIM models, drawings and data;

- The maintenance personnel of the Owner can quickly be familiar with and master the internal institutions, systems, equipment, pipe and other information upon the completion of the project, quickly locate and find out the abnormal equipment, and make timely responses as per drawings and various views display in the as-built BIM model;

- The owner can make simulation of the operation and maintenance emergency management like using the method of 3D visualization for power failure, fire, evacuation and other special items’ simulation as per the as-built model to find out the most appropriate treatment method.