This article is the continuation of a conversation that I started with the blog post depicting the value of BIM for Concrete and continued with from 2D to 3D with rebar detailing. If you’ll remember, I’ve described what I see as four main benefits for a BIM-centric approach to concrete:

- Combines the versatility of 2D documentation with the higher level of fidelity and accuracy of 3D modeling of steel reinforcement and concrete accessories, with minimal effort to produce both.

- Allows users to design and detail with rebar clash prevention in mind to reduce clashes both in the preconstruction and site execution project phases.

- Enables the transition from design to detailed models while respecting both perspectives, following local code requirements, and automating the process of making changes so they are less disruptive to the design process.

- Increases transparency and quality of the model information being used from bidding to procurement by not only providing quantifiable information, but also enabling access to it in collaboration friendly environments.

In this post, I want to focus on benefit #2, and discuss how leveraging rebar clash-detection for concrete can benefit both the preconstruction and execution phases of a project.

Benefit #2: The BIM-centric concrete solution allows users to design and detail with rebar clash prevention in mind to reduce clashes both in the preconstruction and site execution project phases.

There are many practical reasons why having rebar clashing on a construction site is highly undesired, causes serious project delays and therefore significantly increases project cost. This can easily happen in seismic regions when large diameter rebar are used and it is not possible to resolve clashing issues by just adjusting bar shapes on site or when rebar distribution needs to be very dense as typically required for power station structures. More examples can be uncovered.

When a clash is detected, an intervention (change order) is typically sent to detailers as the finding still comes late in the design to construction process.

Clash detection tools like Navisworks can help in such situations, detecting clashes in cases where a rebar model is delivered in 3D earlier than when rebar are being fabricated and installed.

Definitely, best is when a detailed definition of rebar layouts comes already correct from rebar detailers. There are several enablers helping rebar detailers be successful and deliver clean and precise instructions for rebar fabricators and installers. Let’s name these opportunities:

Precise positioning and coordination with other objects

Precise rebar placement mechanisms mentioned above and software intelligence can guide detailers to define rebar positions with respect to all geometrical boundary conditions; both 2D and 3D snapping, increment based guiding, non-overlapping positioning with regards to rebar radiuses and diameters works as a desired clash prevention.

Setting rebar for clash-avoiding behavior

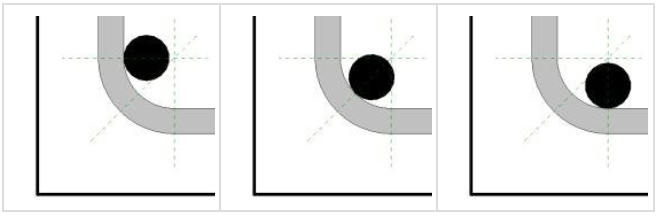

More importantly, Revit rebar objects are born with certain intelligence respecting logic that detailers can define for it. For example, this means that we can set up rebar to behave in order to keep right distance from concrete faces, right distance from other rebar, being still adjacent to each other when rebar diameter changes, or adjust redistribution in function of changing sizes of concrete hosts, etc.

The implanted behavior makes rebar respecting detailers intent and therefore avoiding clashes as they are created and when model changes come into play.

(Imposing constant distances for rebar in Revit)

What we see is what we get

As simple as it sounds, seeing rebar cages in three dimensions and with realistic sizes greatly increases a detailer’s perception and understanding of proposed reinforced concrete configurations.

Unlike with traditional shop drawings where each perspective needs to be presented in a separate view, as rebar cages are defined in Revit we can see the whole rebar cage in a single 3D view, manipulate with it, see it from all angles, and in context of adjacent model elements. All while authoring.

(Dynamic 3D view in Revit)

Early review and 3D model inspection

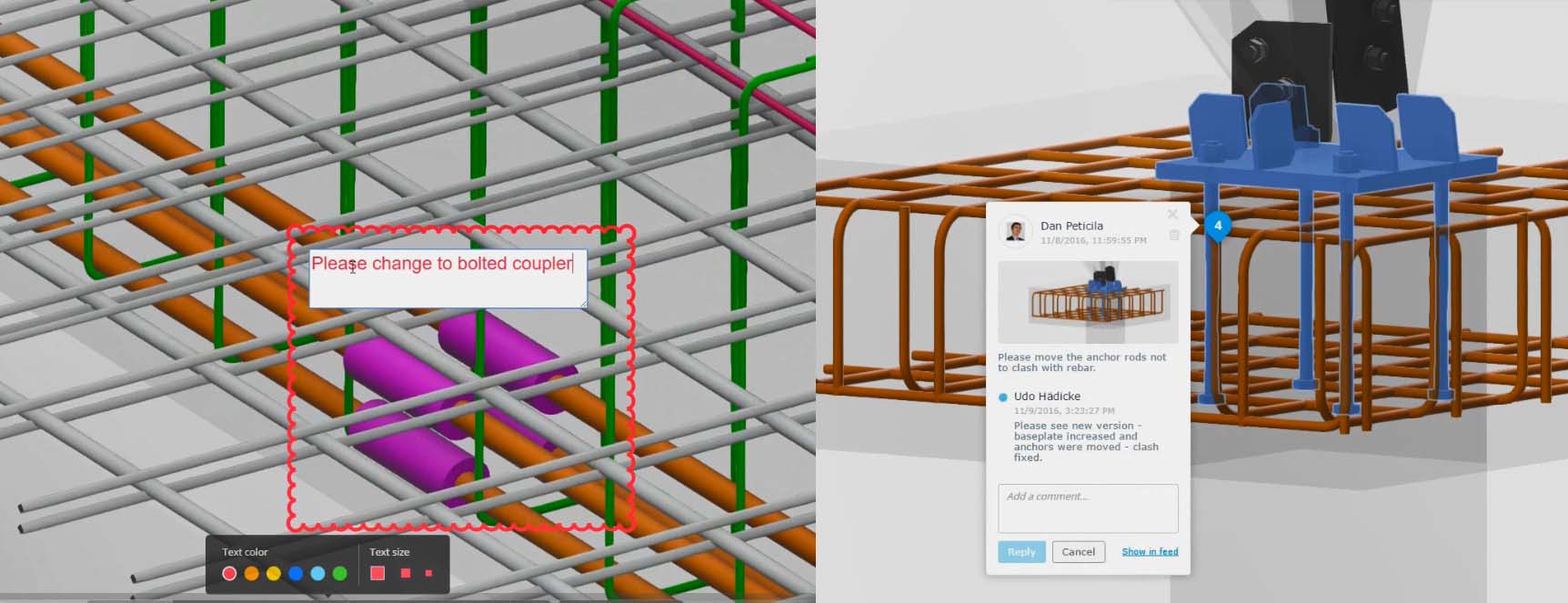

Having a broader 360 perspective with more than a single pair of eyes is usually the recommended method to secure quality for any task, rebar detailing included.

It’s amazing how easy it has become lately to share model information for a review with others.

Simply sharing the Revit model through BIM 360 makes it available via a simple link for stakeholders for inspection / review / commenting / comparison of changes. Exposing a proposed solution to others before it’s locked and stamped as rebar detailing submittals greatly increases the quality of the detailed fabrication and installation recommendations and therefore, again, makes it clash free oriented the moment it leaves a detailer’s room.

(Screenshots from a web browser containing BIM 360 viewer)

All in all, the clash-free rebar reality is the result of a few factors: technology enablers, a detailer’s attitude, and yes … if a contractual clause specifies it as a requirement.