& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

9 min read

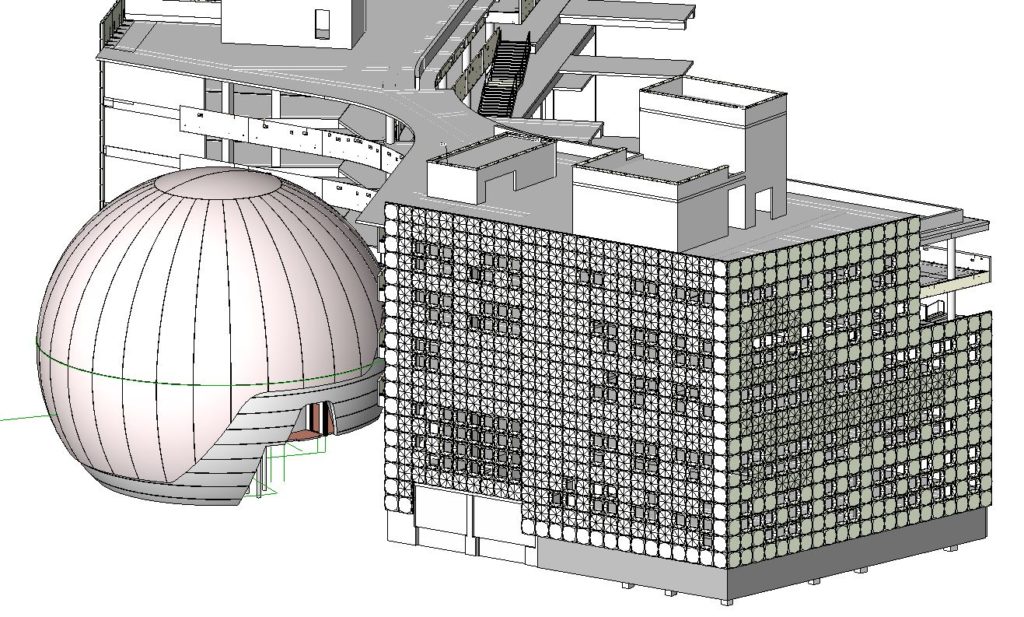

From a spherical planetarium to a building covered in randomized geometric shapes, Miami’s Frost Museum presented considerable technical challenges for Gate Precast. But with Revit, the design and concrete teams were able to collaborate in three dimensions.

When Bryant Luke, vice president of operations at Gate Precast Company’s Kissimmee, saw the initial design of the Phillip and Patricia Frost Museum of Science, he thought it would be the most challenging project the concrete precaster had ever tackled.

Luke wasn’t sure how the firm would manufacture the concrete panels for the five-story, 250,000-square-foot museum building, whose design called for a small number of 3-D exterior “pixels” to be reproduced and scattered in a way that felt random to casual passersby. And that was to say nothing of the adjacent self-supporting, spherical, 250-seat planetarium. “The first thing that hit us, being a manufacturer, was the question of how we’d be able to translate this design concept into something that was production-friendly, something we could actually fabricate,” Luke says.

The challenge, as Gate managers saw it, was to preserve the architectural flourishes of the museum project in a way that allowed it to be constructed on-schedule and within budget (learn how Gate uses precast concrete and design-assist to realize complicated architectural designs) . “We love being a part of these beautiful buildings, but at the end of the day, you have to be able to build them,” says Michael Trosset, Gate Precast’s project manager for the Frost Museum. “The architect wanted something that really had never been done before. The shapes were funky, they were new. The firm was worried about every little detail, as you can imagine. It’s a very marquee project. Changing anything was tough, and it was a task that required us to work hand-in-hand with them. When we had a suggestion, we had to give them a way to visualize it.”

Revit helped the architect, Grimshaw Architects, and Gate Precast use 3D to communicate and coordinate the Frost Museum’s complicated exterior design. Image courtesy of Gate Precast.

Early on, Gate stakeholders concluded that modeling and creating unique molds for each exterior panel of the museum building would require too much time and money to be practical, and would ultimately hold the project back. Rather than create completely new molds for each larger panel, the team devised a system in which the individual molds for each “pixel” were interchangeable, and could be popped in and out of larger panel frames. This modular system, which was inspired by lessons learned during the firm’s work on the Perot Museum of Nature and Science in Dallas, allowed the Gate team to bring to life the incredibly varied project design, while limiting the number of individual precast molds.

Mock-up of the molds for the exterior of the Frost Museum. Image courtesy of Gate Precast.

“Through some previous projects, including the Perot Museum, we really learned how to get randomness in design by utilizing rubber forms or plugs,” says Trosset. “Without having to rebuild the master mold every time, we could just pop in a specific ‘pixel’ piece, and that allowed us to get that randomization in the panels. Before we even started pouring concrete, the Revit model allowed everybody to visualize just how these pieces were really going to look in a 3-D scenario.”

Christian Hoenigschmid, Associate Principal at Grimshaw Architects, says that Revit was pivotal to helping the design team in the initial design phases, as well as when Gate Precast was appointed to figure out how to bring the randomized building exterior to life. This design element was central to the project, as the geometric shapes are meant to convey a sense of change and movement as people passed by the project, and as the sun moves across the building façade throughout the day. The design also had a thematic tie-in with the science museums says Hoenigschmid, as it illustrated how all the complexities of life arise from relatively few simple building blocks.

“In early discussions with Gate prior to their appointment, we together started to work out how this façade was going to be panelized,” says Hoenigschmid. Through 3D work in Revit, Gate could communicate challenges to us and assess the pros and cons of both horizontal and vertical panel layout options.”

Initially, says Hoenigschmid, the project team had planned on horizontal concrete panels. But, through their modeling work in Revit, the Gate team realized that vertical panels were more feasible. Because the joints between the large panels weren’t meant to be any more noticeable than the reveals between the smaller “pixels” from which the panels are comprised, Grimshaw allowed the modification.

“We had no aesthetic preference as to how the panelization of the façade worked, as long as it achieved the design intent of the façade while working both structurally and economically,” says Hoenigschmid. “Arriving at that understanding was one of the crucial aspects of the back-and-forth nature of this collaborative process.”

Converting the design for the Frost Museum into a buildable model was only part of Gate’s challenge. The team also relied heavily on Revit to assist with the manufacturing, shipping, and installation processes for the precast concrete — all of which presented their own considerable hurdles. In the mold manufacturing process, Revit allowed the Gate team to export shop tickets directly from the BIM model. Luke says that this resulted in a 500 percent time savings, compared to designing and manufacturing the molds using two-dimensional design processes.

Manufacturing the exterior “pixel” forms on the Frost Museum. Revit allowed the Gate team to export shop tickets directly from the BIM model. Image courtesy of Gate Precast.

“Some of the details might not have even been transferrable using a 2-D methodology,” Luke says. “If we had to rely only on 2-D, we would have had to make a lot of mock-ups using Styrofoam or wood, work out the details on what we got wrong, and then come up with the correct piece. It would have been substantially more work.”

Another advantage of the 3-D modeling process enabled by Revit, says Gate drafting manager David Swords, is that it promoted collaboration. “This allows you to work-share,” Swords says. “In 2-D, you couldn’t have more than one person working on the same thing. We were able to break up the model and have several teams from all over the country working in it at the same time.”

With BIM processes, Luke says, manufacturing the molds for all of the individual “pixels” for the Frost Museum took just over two weeks. If Gate had been restricted to 2-D drawings, he says, that timeframe would have shot up to around 14 weeks. “An ownership team wouldn’t have wanted to wait the amount of time it would have taken in two dimensions,” he says. “A project like this would have been almost undoable.”

“Revit is an invaluable tool on the logistics side,” says Luke. “Everybody can log into it, no matter where they are, and see real-time information together. For processes like shipping and installation, we absolutely rely on the ability to look at a 3-D model instead of multiple two-dimensional drawings.”

The project required Gate to produce not only the panels with the randomized “pixels,” but also curved, 50,000-pound pieces – which the Gate team likened to “orange peels” – for the dome-shaped planetarium. The pieces were not only massive and unwieldy, but also unique, requiring project managers to grapple with the problem of how to store them and ship them safely to the construction site.

“We used Revit to model the trailer racks that we used to ship the panels,” explains Swords. “We were able to take one panel, isolate it in the model, rotate it, and then, along with our production and yard personnel, figure out how we could store it and ship it. We actually made custom trailers to fit the panels.”

Gate precast used Revit to figure out how to ship the planetarium panels. They modeled and fabricated custom trailers to fit the panels. Image courtesy of Gate Precast.

“We decided to lay out the panels on the trailers in the model to see how much they would overhang the trailer,” adds Luke. “Visualizing all of that was a huge help.”

Gate utilizes Revit to simulate the installation of precast concrete panels — a process that proved especially valuable for the domed planetarium. The planetarium was a structural, self-supporting, architectural precast, and it required the construction team to work around the clock for two and a half weeks to install the 32 “orange peel” panels with a specialized 550-ton hydraulic crane.

Gate Precast used Revit to simulate installation for the technically challenging domed planetarium. This allowed the team to work out the details for planning installation virtually before moving to the field. Image courtesy of Gate Precast and Miami in Focus.

During simulations, the Gate team caught a major potential problem on the planetarium, well before the dome was scheduled to be constructed. The design plans called for standard 3/4-inch joints between the concrete “orange peel” panels, but simulations showed that these joints would be too narrow to allow installers to extract the thick cables used to lift the panels into place. The joints needed to be widened to a full inch.

“We were able to show that to the design team in the model, and everybody understood it,” Trosset says. “It’s hard to explain something like that over the phone. When you say, ‘I have to make the joint bigger,’ it’s probably the last thing they want to hear, because of waterproofing concerns. But being able to show them why we needed it streamlined the whole process.”

Luke estimates that the installation timeline would have ballooned by at least three weeks if the Gate team hadn’t first tested the process in the Revit model. “Without the simulation, nine times out of ten, we would have attempted to lift a piece into place and then realized that we needed custom rigging, and then had to wait for the rigging to be manufactured,” Luke says. “With Revit, we were able to do everything digitally before the first panel was even produced. It all worked beautifully.”

Luke jokes that Revit has been both “a blessing and a curse” for Gate – meaning that the tool allows the firm to complete more complex jobs more quickly, but also continually increases expectations. “Revit has allowed us to do things we couldn’t have done ten years ago,” Luke says. “When the Frost Museum job came in, we said, ‘Oh my God, this is the toughest thing we’ve ever seen.’ Four years later, we look back at this job, and we say, ‘Piece of cake.’”

By clicking subscribe, I agree to receive the AEC newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.