& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

9 min read

Written by 01/31/2018

Set in the heart of Montreal, the new Centre hospitalier de l’Université de Montréal (CHUM) is changing the landscape of the Canadian metropolis. Occupying two full blocks, CHUM is the largest healthcare construction project currently being built in North America—and among the largest in the world. Born from the merger of three existing hospitals, it replaces outdated facilities and joins them to form a new healthcare campus on a single site. As the anchor of Montreal’s centrally located health district, the development will seamlessly combine teaching, medical research, and patient care—solidifying the city’s standing as a hub of excellence in health and science.

Made up of three 21-story towers that comprise a total of 3,597,000 square feet, the facility is, quite simply, massive. Despite its large size, the trio of interconnected towers—which communicate and relate to one another, while retaining individual identities—lend a human scale that’s essential to a healthcare community. The CHUM’s architectural design also combines historic architectural artifacts, such as Montreal’s Saint-Sauveur steeple, with a nuanced amalgam of cladding materials to create a juxtaposition that redefines the surrounding district’s identity. More than a comprehensive center for medical care, research, and education, the site is also a cultural destination—incorporating 13 large-scale works of art.

The project’s first most important phase completed in 2017 and accounting for 85 percent of the programming included the hospital complex, clinical ambulatory center, logistics center, pharmacy, laboratories, and underground parking. Scheduled to conclude in 2021, the second phase will feature a learning center and library, auditorium, and finalization of the clinical offices. Even prior to completion, the CHUM project is groundbreaking for all of its stakeholders—from the city and its university-based hospital system, to its thousands of patients and staff, to the design team taking it on.

Delivering this monumental project took a monumental team effort—bringing together one of the world’s leading design firms and one of Montreal’s most celebrated design studios. CannonDesign, with 23 offices across the globe, including in Montreal, brought industry-leading healthcare expertise to the table, as well as experience designing more than 130 acute care hospitals and/or major expansions. With offices in Montreal, Ottawa, and Toronto, NEUF architect(e)s is a team of creative professionals that have been contributing to Montreal’s urban landscape since 1971. NEUF brought unrivaled experience delivering innovative architecture and is currently involved in projects across the Americas, Europe, and Asia.

Teaming up with CHUM, CannonDesign + NEUF architect(e)s each brought their unique strengths to create a truly seamless partnership.

“Because of our size, and our experience working in the healthcare market and on technically complex projects, we brought a level of expertise to this project that no other local firm had. But what NEUF offered was a deeply rooted understanding of Montreal and Quebec. NEUF helped us translate the design into what would really resonate in Montreal,” adds Silva. “A good marriage of two very different skill sets came together to deliver the CHUM, which is a truly remarkable, one-of-a-kind building.”

Jose Silva, Executive Director at CannonDesign.

To enhance collaboration, CannonDesign + NEUF architect(e)s, along with the engineers, contractor, and building operators, co-located in the same Montreal office throughout the project. “It was one of the most successful integrations of two offices that I’ve been a part of,” says David Goyne, one of CannonDesign’s Project Architects for CHUM.

Beginning with the bidding process itself, back in 2009, the design team went big and bold.

The original request for proposals (RFP) called for 55 percent of the program to be housed in a series of mid-rise buildings during phase one. But the team quickly recognized an opportunity for improvement and proposed a high-rise solution that would build an additional 30 percent of the program up-front—incurring more costs early on and reducing the risk of significant escalation later.

“Challenging the RFP was such a bold move—telling the client that we could essentially do this better and deliver a fully functioning hospital in five years instead of ten. Using Autodesk Revit for blocking and massing studies was very important for us. It allowed us to do quick design studies that, in the end, enabled us to propose this alternative solution. That’s what ultimately won us the project.”

David Goyne, Senior Associate, VDC Leader at CannonDesign

Not only is CHUM the largest project either firm has worked on to date, it’s the largest healthcare facility ever modeled in Revit. With a building area of nearly 3.6 million square feet, the project required the team to redefine its approach to BIM, as well as to project workflow, delivery, and even staffing. “We knew that if we tried to work in a traditional way—using traditional tools and delivery systems—it would be extremely difficult to execute a project of this size successfully,” explains Goyne. As an Autodesk customer, CannonDesign + NEUF architect(e)s had access to the full portfolio of design software products and solutions. However, due to the CHUM project’s grand scale, the team primarily utilized Revit and Navisworks, as well as a variety of other complementary tools.

In late 2011, the design team hosted a project delivery meeting to create a roadmap for the design and documentation process. The team brought together all of the project participants, including each firm’s quality control and BIM leaders, the project’s BIM consultant, Boston-based CDV Systems, as well as management, planning, and technical leaders. The protocols that were then established applied to both routine and BIM-specific tasks—from email correspondence and transmittals to building equipment content and reference details in the Revit model.

Managing the project’s massive amount of data and maintaining consistency among its numerous collaborators were the design team’s most significant challenges. Adopting CannonDesign’s Single-Firm, Multi-Office (SFMO) approach early in the process allowed the project team to bring together 180 individual staff across 15 different offices and multiple time zones. “The combined approach of bringing together healthcare experts, technical leaders, and production staff, and using the right tools at the right time, allowed the team to turn these challenges into opportunities to become more effective and efficient.” At the beginning of the project, we chose Revit as our primary platform,” said Goyne. “We had 41 different architectural models and more than 150 models when you take into account our consultants. That’s a big amount of data to manage, and Revit was able to handle that quite successfully for us.”

Beyond handling a lot of data, Revit provided the team with an ease of workflow and management. “It allowed us to break out various pieces of the project into different construction deliverables and package teams,” said Goyne. “At the same time, we were able to link that information back into each of the models for better management and interoperability. That approach has been quite successful throughout the course of the project, and we’re very happy with Revit, in particular.”

One Revit workflow that was especially useful for a massive production team speaking two languages was the exclusive use of keynotes to standardize technical language in the drawings and specifications. Each keynote contained both English and French text and could be edited by a set group of people for quality control purposes before being implemented throughout the production models by the larger team.

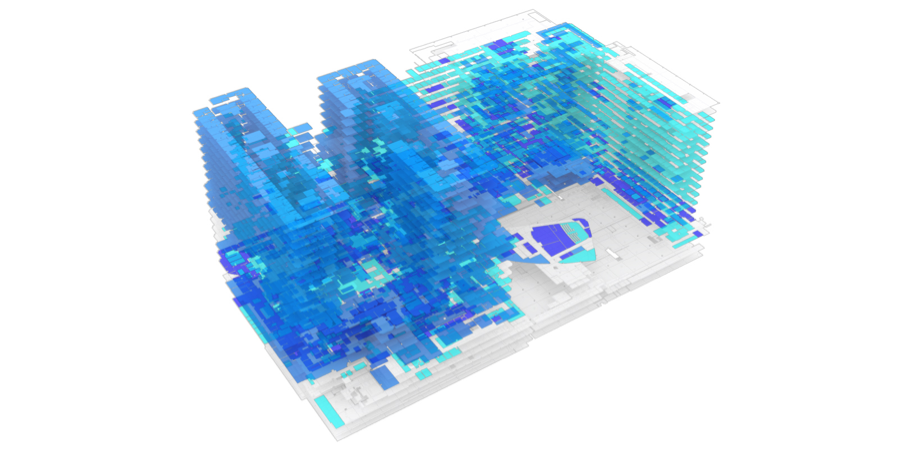

Figure 1: Diagram for departmental and unique rooms

The design team also found Navisworks incredibly useful throughout the CHUM project—especially when they started to do clash detection with mechanical and structural systems.

“There was such a huge amount of content in the models, including more than 200,000 pieces of medical equipment. It’s very difficult to coordinate that with other building systems. Navisworks helped us identify clashes so that we could isolate them and quickly make the necessary corrections.” David Goyne, Senior Associate, VDC Leader at CannonDesign

As a result, the team was able to avoid costly and time-consuming rework. In addition, Navisworks was indispensable for illustrating design and coordination issues with CHUM and the hospital staff. For instance, to demonstrate that sight lines to patients would be maintained, Navisworks allowed the design team to walk user groups virtually through the center’s dialysis department with a first-person perspective—much like a video game.

While Revit provided most of the horsepower throughout the project, not every task required such advanced tools. In fact, by using other technologies for data management, communication, and/or collaboration, the team gained some big efficiencies. Revit was compatible with other tools the design team was using—including custom plug-ins it developed—giving the team a great deal of versatility and time savings. For example, the design team and owner group used PDFs for internal communications, editing shared documents with an outside integrated collaboration solution (2D). They could mark up PDFs on that 2D platform, while a designer in another office could pick up the changes in the Revit model in real time. According to Goyne: “The ability to interface directly with other programs facilitated our workflow and helped us be successful.”

The use of Revit with other BIM-supported technologies allowed the project team to leverage the Revit model and its interoperability with other software to push BIM well beyond developing traditional two-dimensional construction documents. “This enabled better consistency across multiple deliverables; more effective daily quality assurance; early resolution of trade coordination issues; and assisted in explaining sometimes-complex concepts to the end users,” says Goyne.

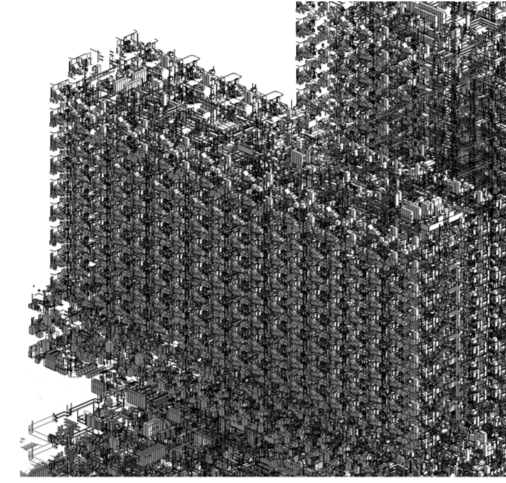

Figure 2: Equipment model extract

As a result of their experience on the CHUM, CannonDesign + NEUF architect(e)s have begun a standardization of typical Revit rooms and families to be used as a template for future healthcare projects. In addition, the CHUM model structure, and management of model sizes and integrity, have set a baseline standard for other large projects.

“BIM helped us produce a higher-quality end product that is not typically seen in a Public-Private Partnership construction delivery method. Using Revit enabled our team to work seamlessly on a single platform across multiple offices, while increasing productivity and consistency, reducing errors, and streamlining our workflow,” said Goyne.

Upon completion of phase two in 2021, CHUM will represent the largest single-site hospital on the continent. In the meantime, this fully functioning institution will continue to enhance both the urban and healthcare landscapes of the city it calls home.

Images courtesy of CannonDesign + NEUF architect(e)s.

By clicking subscribe, I agree to receive the AEC newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.