Traditional structural engineering workflows involve a variety of challenges. Structural engineers typically start the design process by getting familiar with the architect’s design by interpreting architectural drawings or general 3D conceptions.

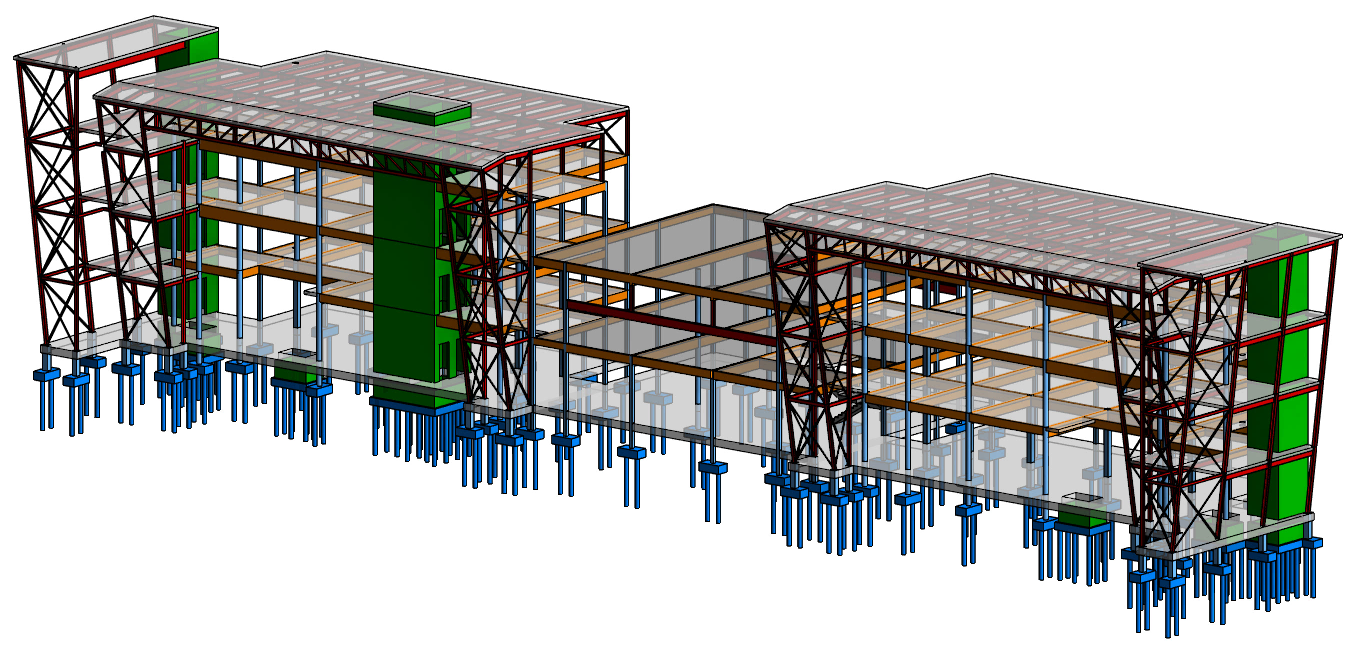

From those drawings most structural engineering offices will create at least two different visions of the project by creating a design of the physical models for documentation, and creating various analytical models for analysis. These analytical models must be consistently coordinated with respect to general framing layout, material and section properties, and loading.

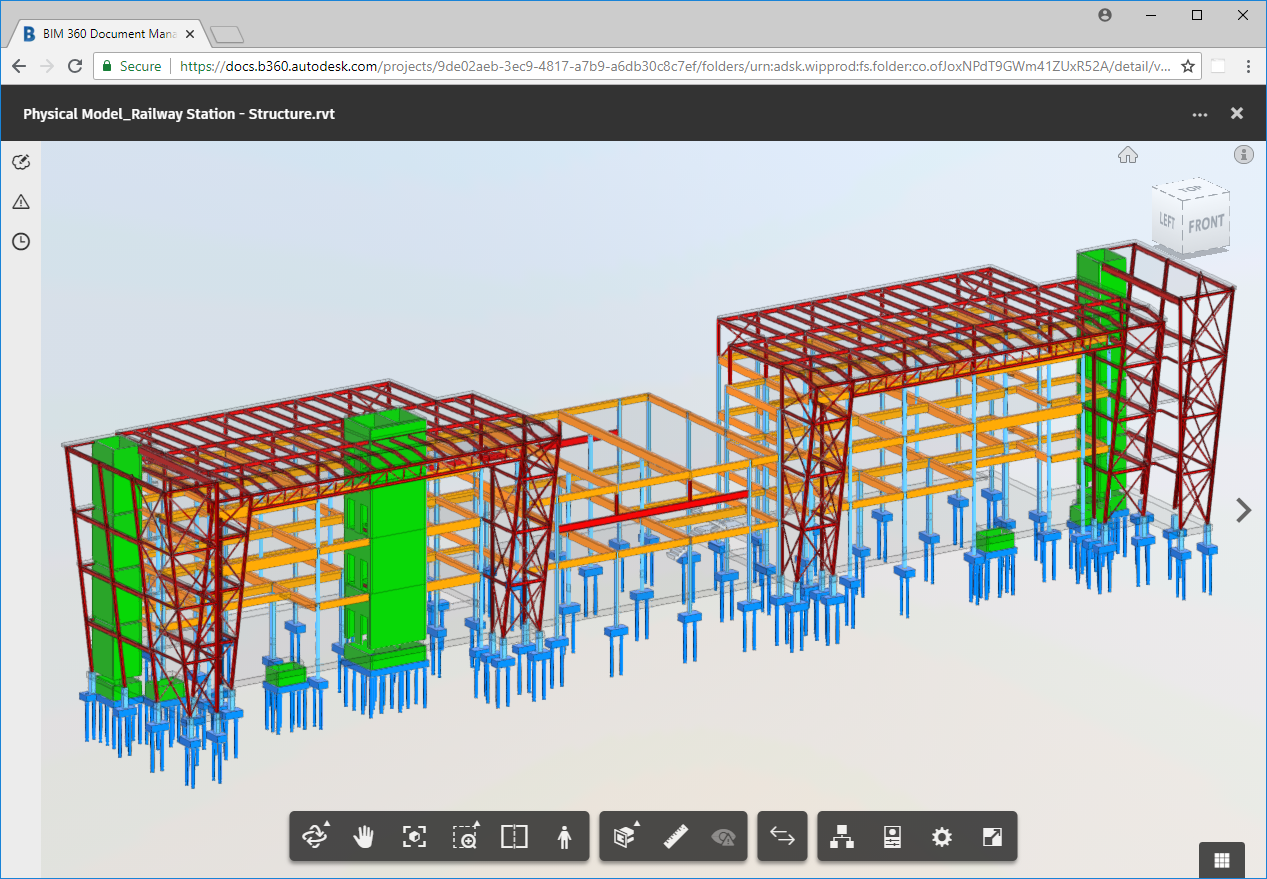

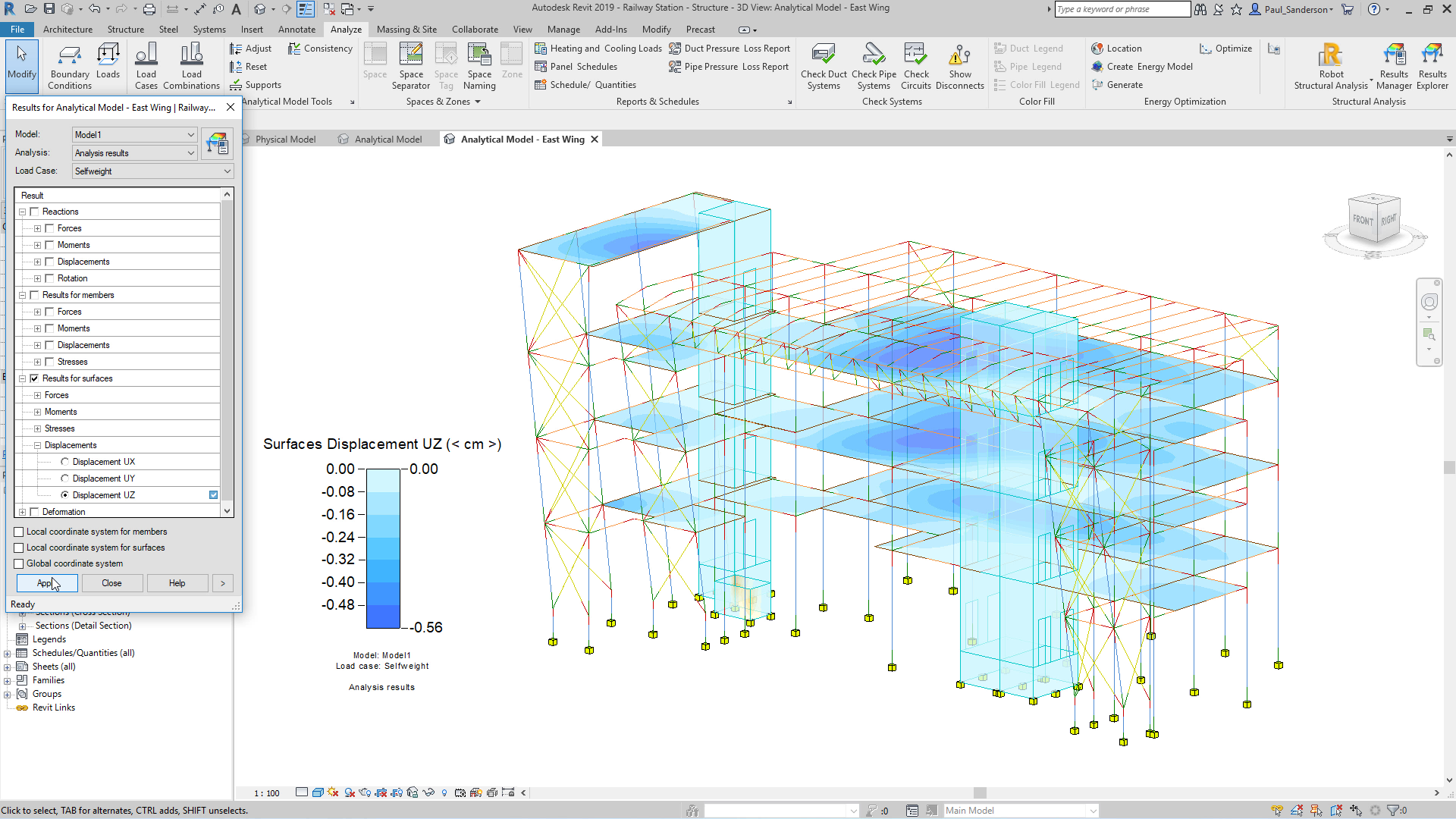

In Revit software, the physical model and the associated analytical model (which contains the boundary conditions and load definitions used for analysis) are created concurrently.

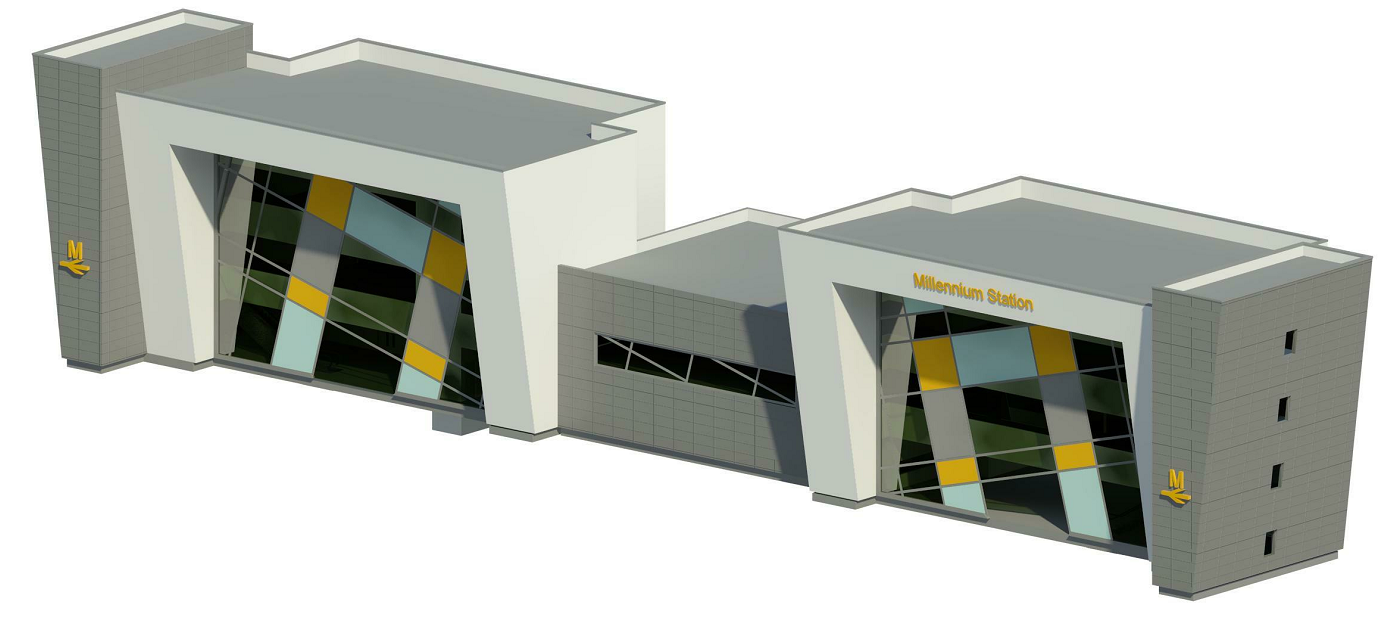

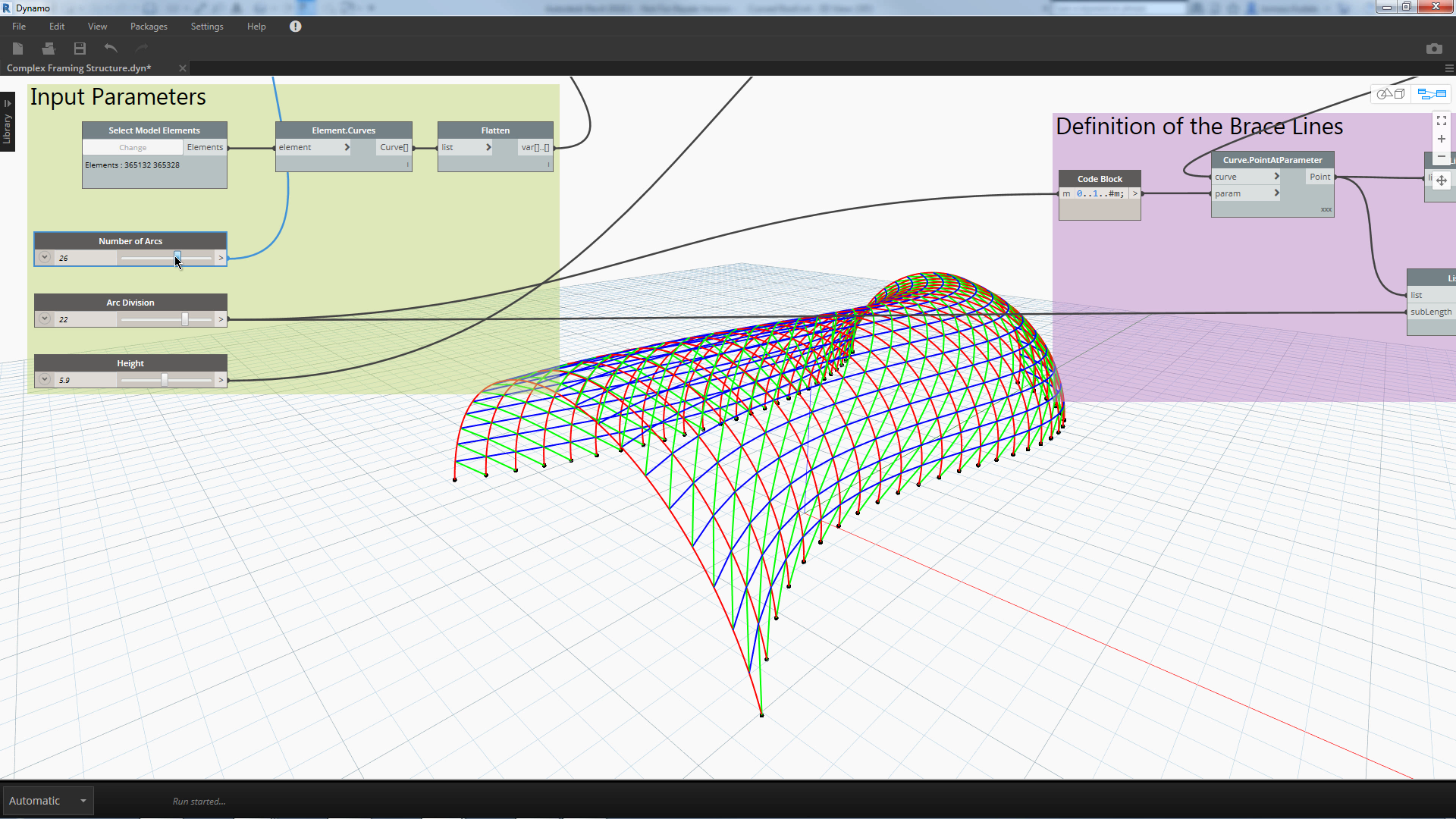

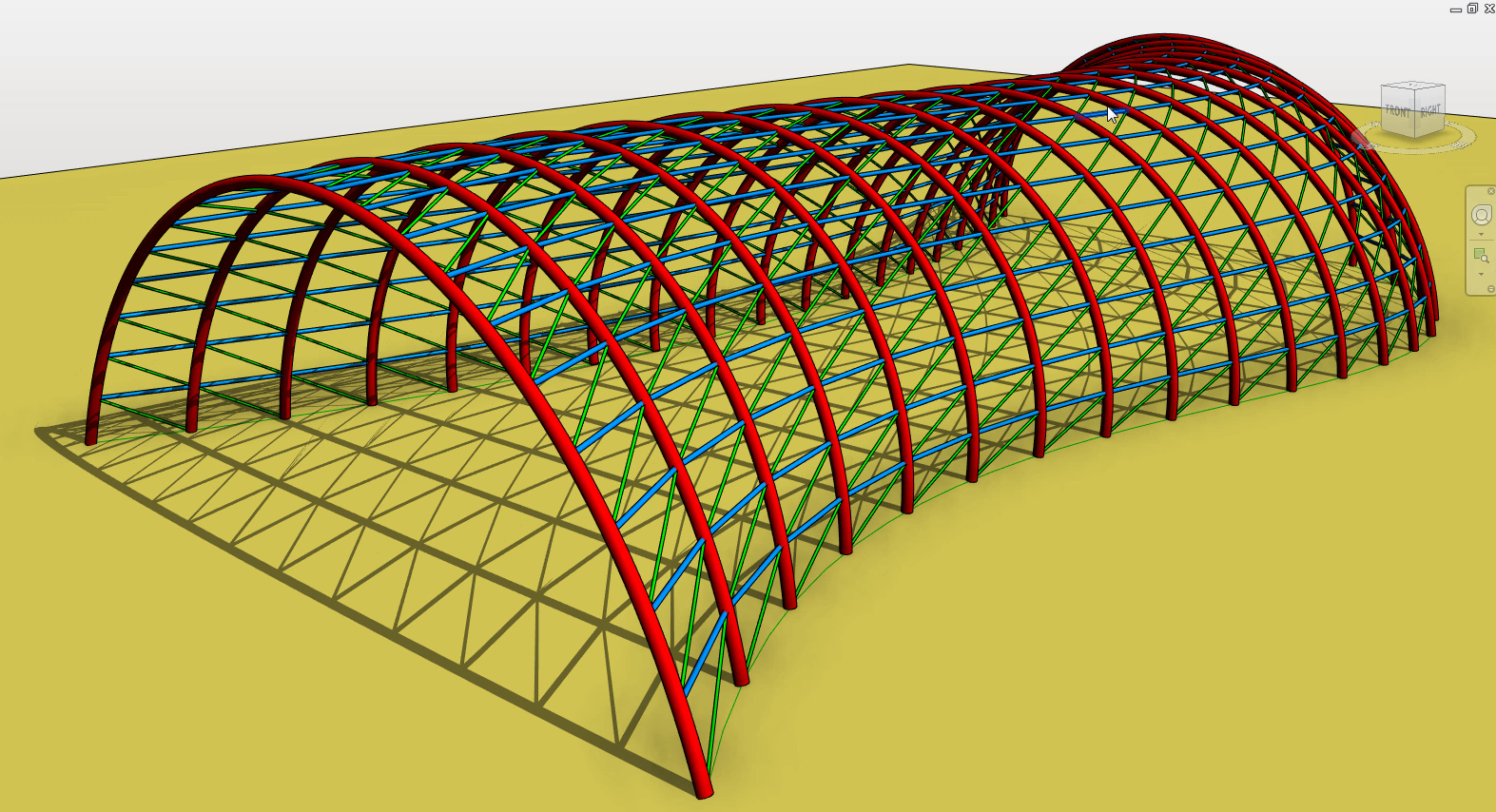

This modelling process can be done using traditional native Revit tools, or it can be exported by using Dynamo. The visual programming interface of Dynamo for Revit provides structural engineers with the tools to build complex steel structural models with minimal energy and make their own structural design tools. Dynamo allows structural designers and engineers to design organic and optimized steel structures faster than with traditional modeling tools by using computational methods.

They can access and edit building parameters more effectively than traditional hard coded tools allow. They can iterate and evaluate multiple building design options with ease, and build structures based on natural and mathematical principles.

If the structural designer/engineer creates both the physical and the analytical model in Revit, the same data does not need to be entered in several different software applications multiple times for different purposes.

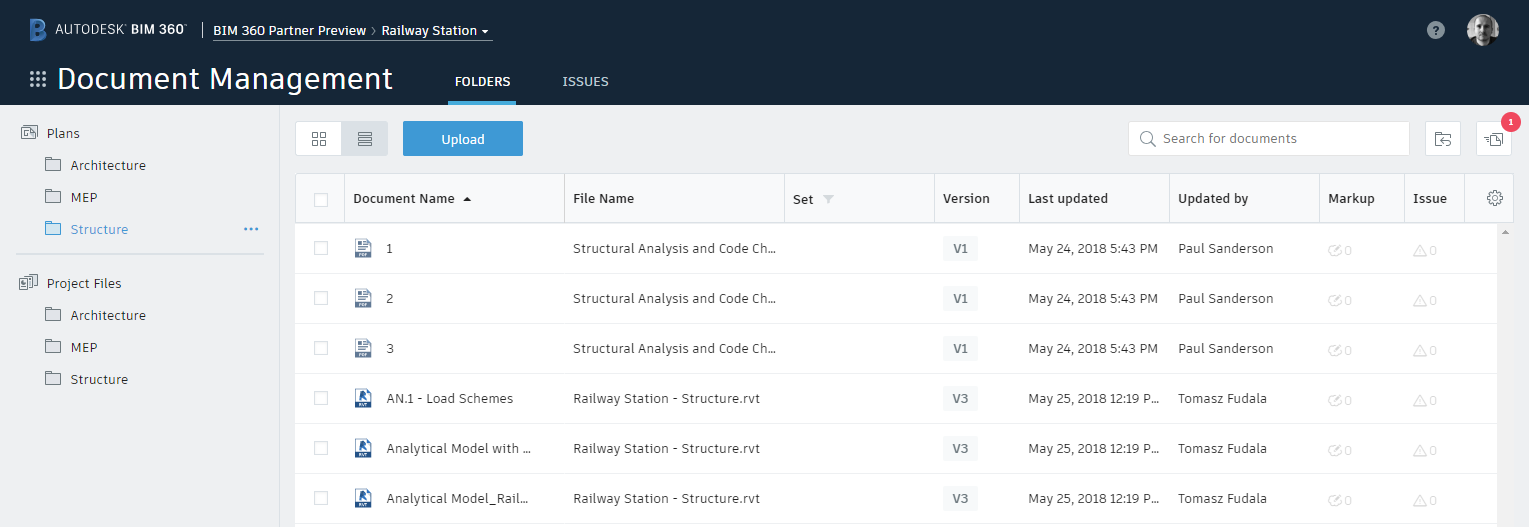

Rather than working in siloed systems structural designers, engineers and detailers can use BIM 360 Docs. BIM 360 Docs integrates the entire project workflow from design to construction across one common data platform.

Structural designers can use the Publish Settings tool in Revit to select views and sheets of the model to publish them to the cloud.

These selected views and sheets are automatically extracted in the BIM 360 Docs environment to give extended teams easy and instant access to the project information via web or mobile.

Then the extended team of structural engineers can easily review what has been done in Revit and the current state of the structural project.

When project teams have the right information at the right time, work happens faster. BIM 360 Docs lets them publish, manage, review and approve all drawings, documents and models — anytime, anywhere.

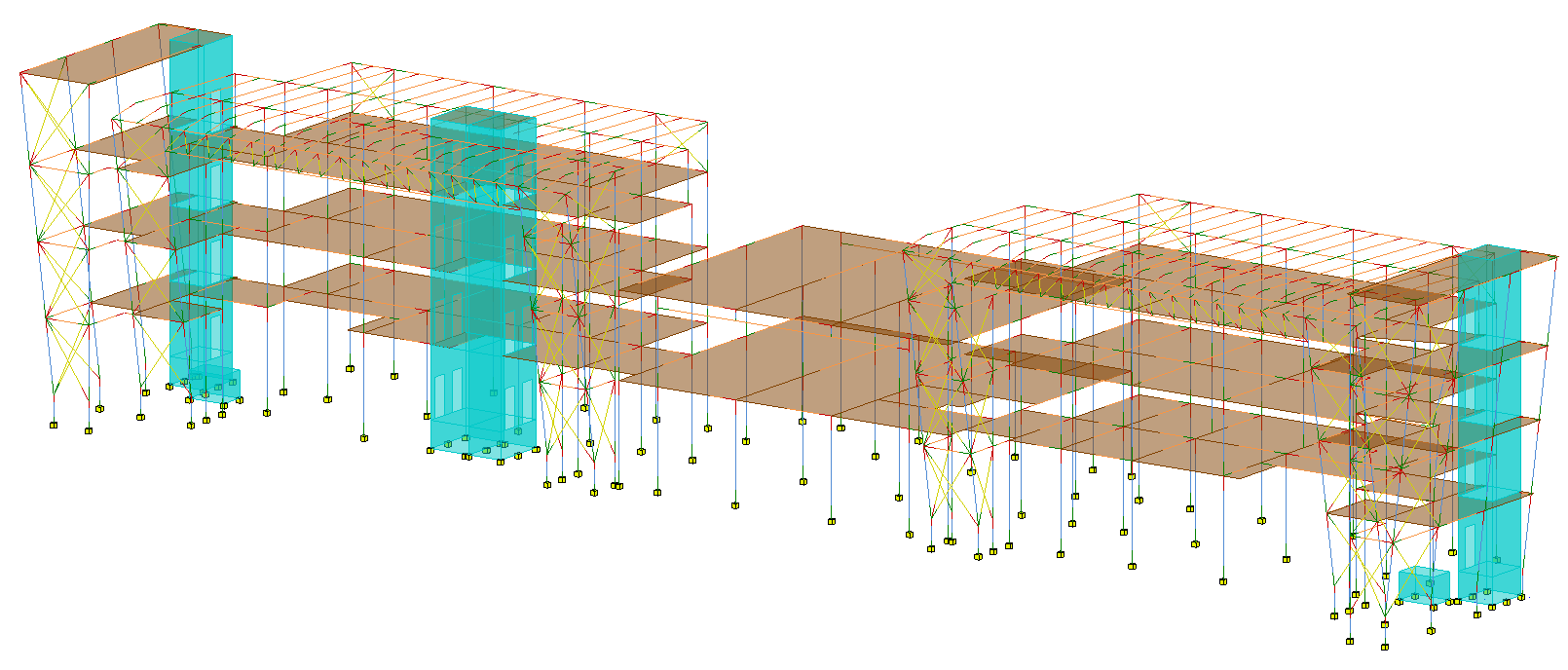

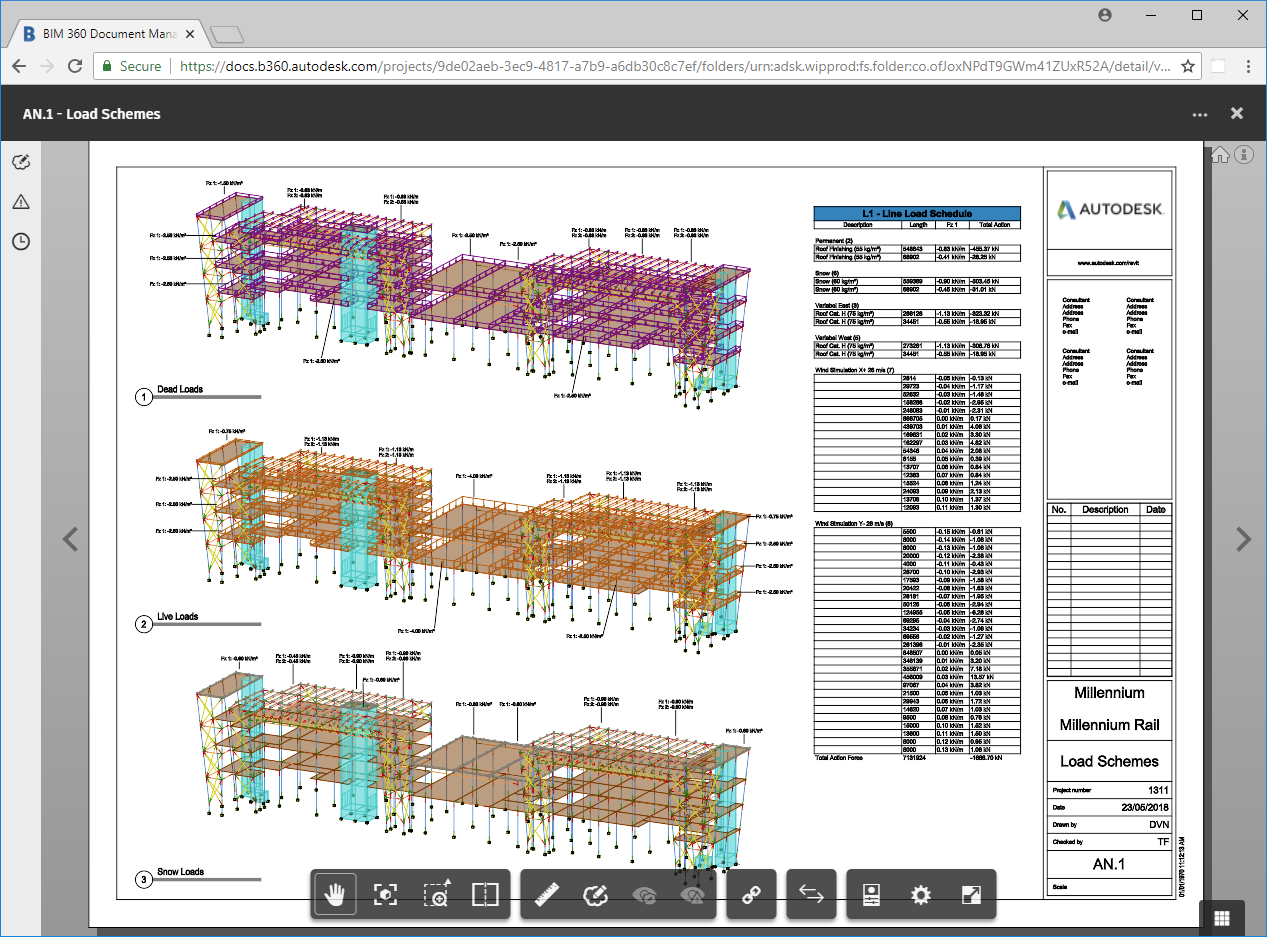

With access to the project data, a structural engineer continues the design process by performing structural analysis and running code-checking optimization.

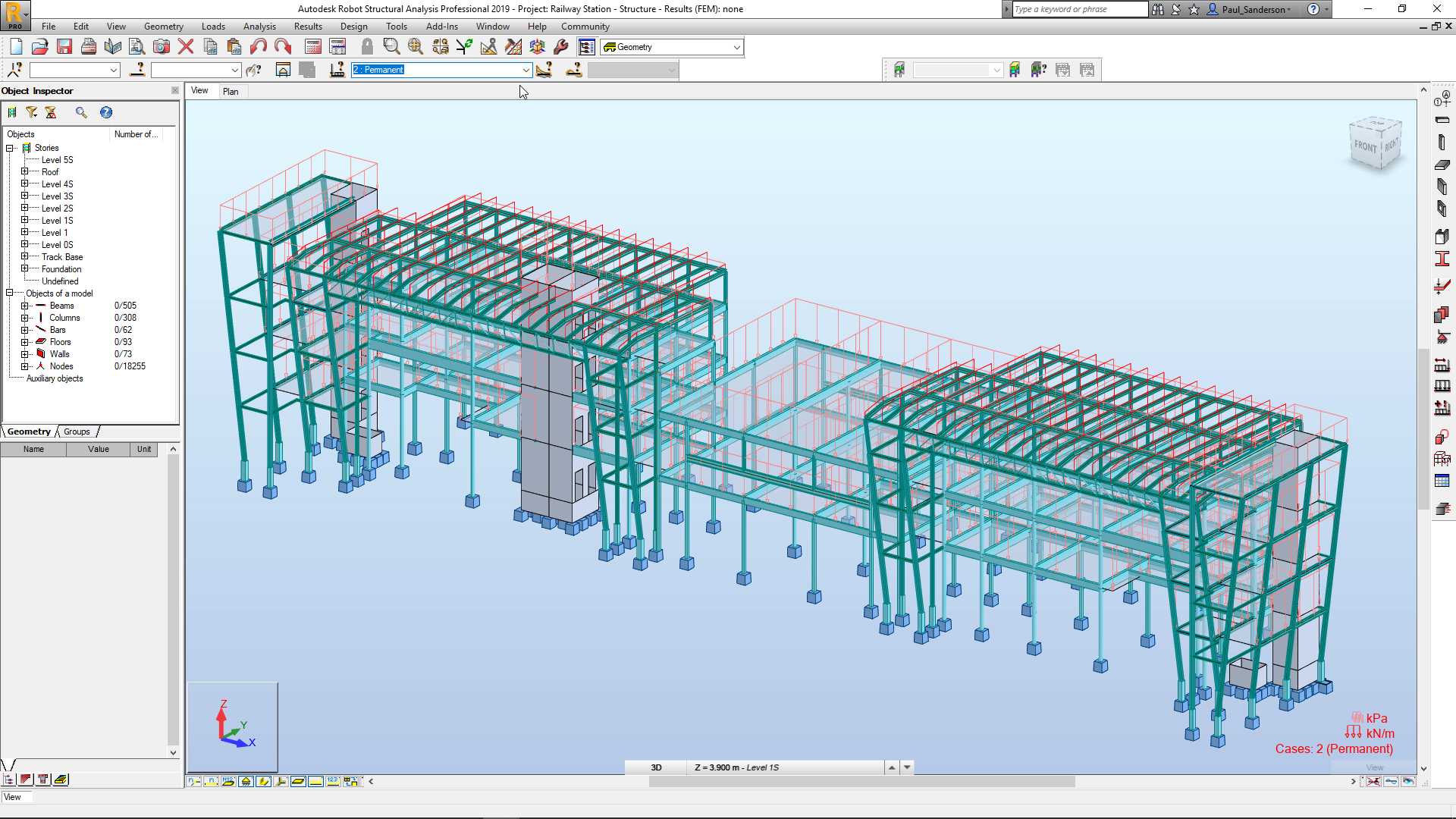

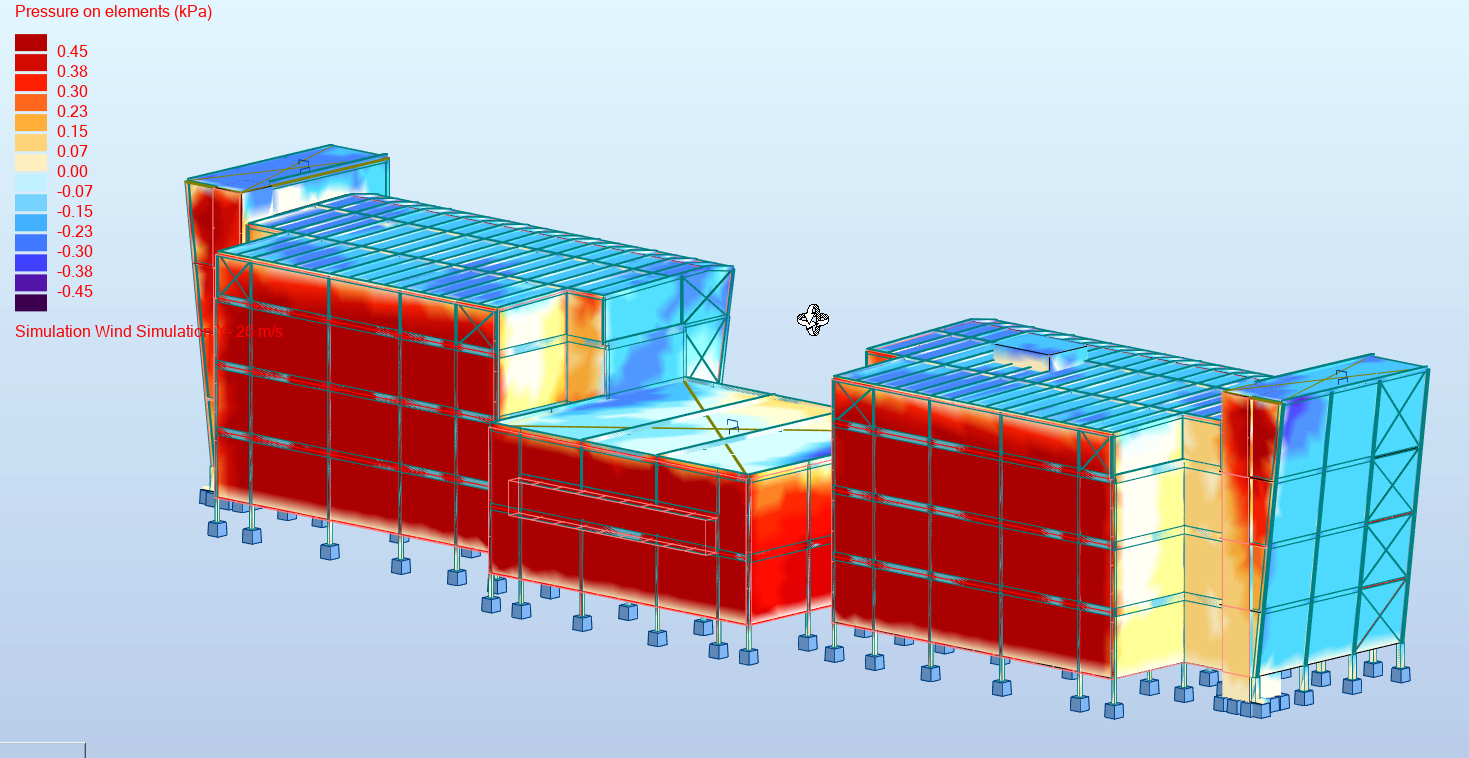

The Revit analytical model can be sent to Robot Structural Analysis Professional with all the information needed for structural analysis, including boundary conditions and loads.

Once the analysis has finished, the engineer can easily explore all results and start the design of structural elements.

Robot Structural Analysis Professional is a powerful tool not only for calculations, but also for visually exploring results.

With multiple ways of presenting analytical results and the ability to easily access them, structural engineers can very quickly prepare the final structural documentation for review by project stakeholders.

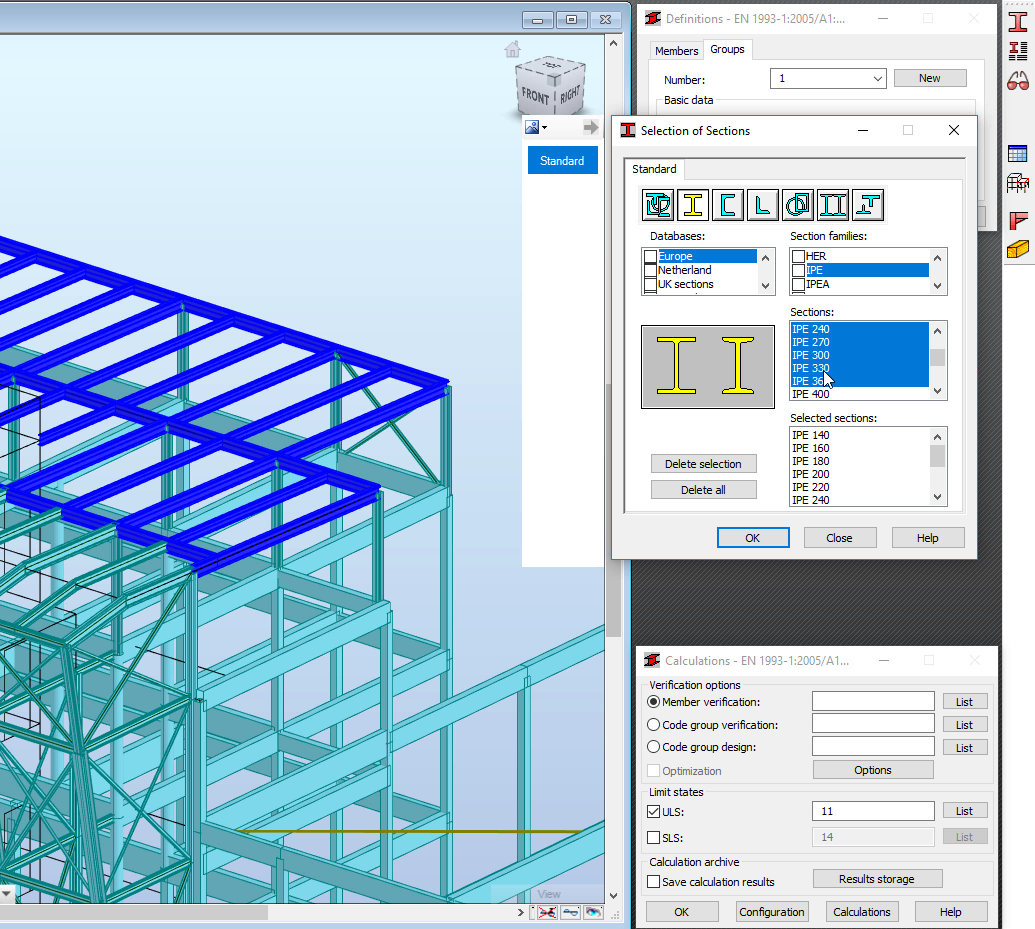

Using Robot Structural Analysis Professional, the engineer can run code checking to verify and design steel members based on a wide variety of national and international codes.

The first step in designing structural steel is to organize the bar elements (beams, columns, braces, etc.) into member groups. Each member in a group will be assigned the same section by the design process.

Once the design group is optimized a simple Change All button allows all new sections to be applied to the model.

When design changes and analysis have been completed by the engineer, the information can be brought back into BIM 360 Docs to allow the designer to review the design changes (the updated physical model /steel sections profiles).

Also here structural engineers can upload their structural analysis and code-checking documentation in the PDF file format.

Results can be easily stored and explored in the Revit environment, enabling users to explore and document results and make effective design decisions. Structural Results Storage and Results Exploration tools delivered by the Structural Analysis Toolkit enable users to explore and document results. They can use this information to understand the structure’s behavior, view consolidated and detailed results, update documentation, and make further effective design decisions.

Once the Revit model has been updated after the analysis and code-checking process the structural engineer can upload a new version of the Revit project to BIM 360 Docs.

Then the structural designer can access the updated optimized model by the structural engineer via BIM 360 Docs.

Using the Compare tool, the structural designer can get insight into what has been changed in the model.

BIM 360 Docs has integrated change visualization that lets users compare the changes between two selected versions of the project.

This summary provides a quick overview of changes made by the structural engineer during the code-checking process.

With BIM 360 Docs, structural teams can manage 2D plans, 3D BIM models, and any other project documents. This streamlines the connection between design and fabrication.

In my next post I will be continuing this workflow… Stay tuned..,

To access Revit, Robot Structural Analysis, Advance Steel, and more essential BIM tools, subscribe to the Architecture, Engineering & Construction Collection.

Steel Workflow from Early Concept to Fabrication using AEC Collection – Part 2