In this blog post, I’ll continue the subject I started a few weeks ago. In the part 1 I covered how structural designers and engineers can collaborate and how AEC Collection helps them connect design with analysis. In this part let’s focus on verification of steel connections, detailing and fabrication.

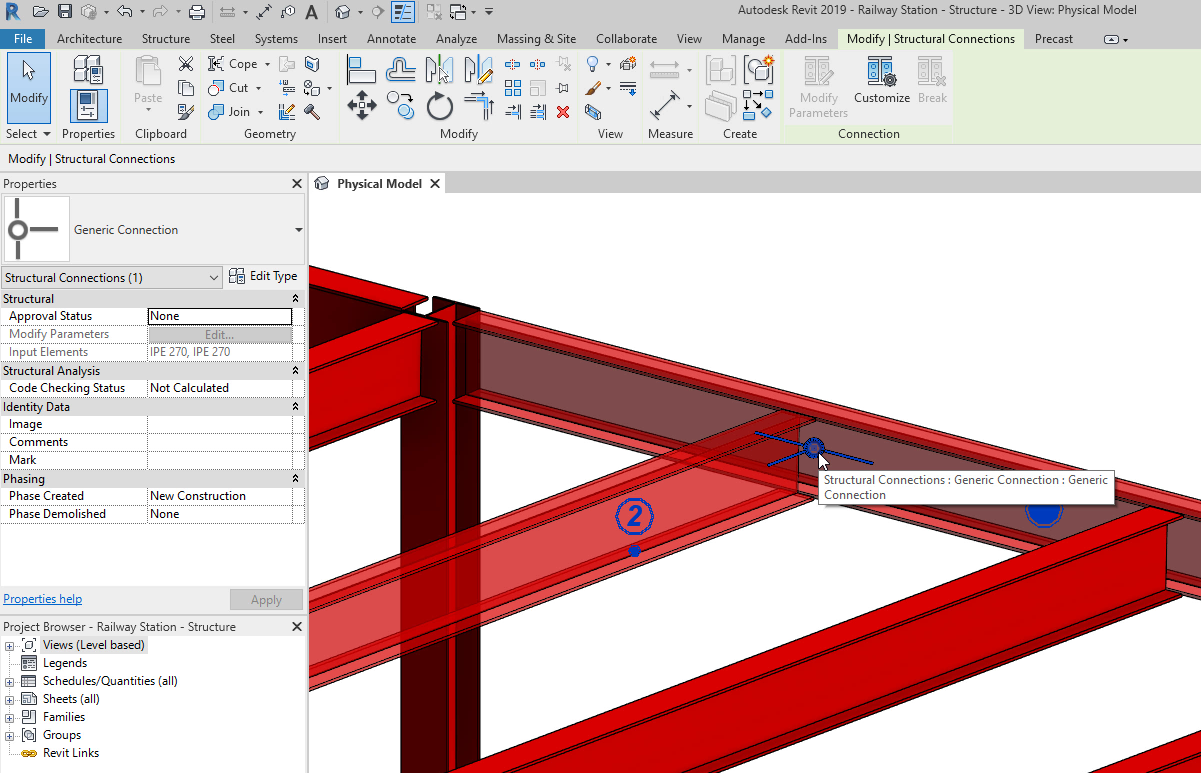

During the project process from design to detailing, there are many discussions between the engineer, detailer, and fabricator about how to connect the multi-material framing elements like beams, columns, and bracings. In this case in Revit, a structural connection object can be placed to supply information about the desired connection and define the relations between the elements.

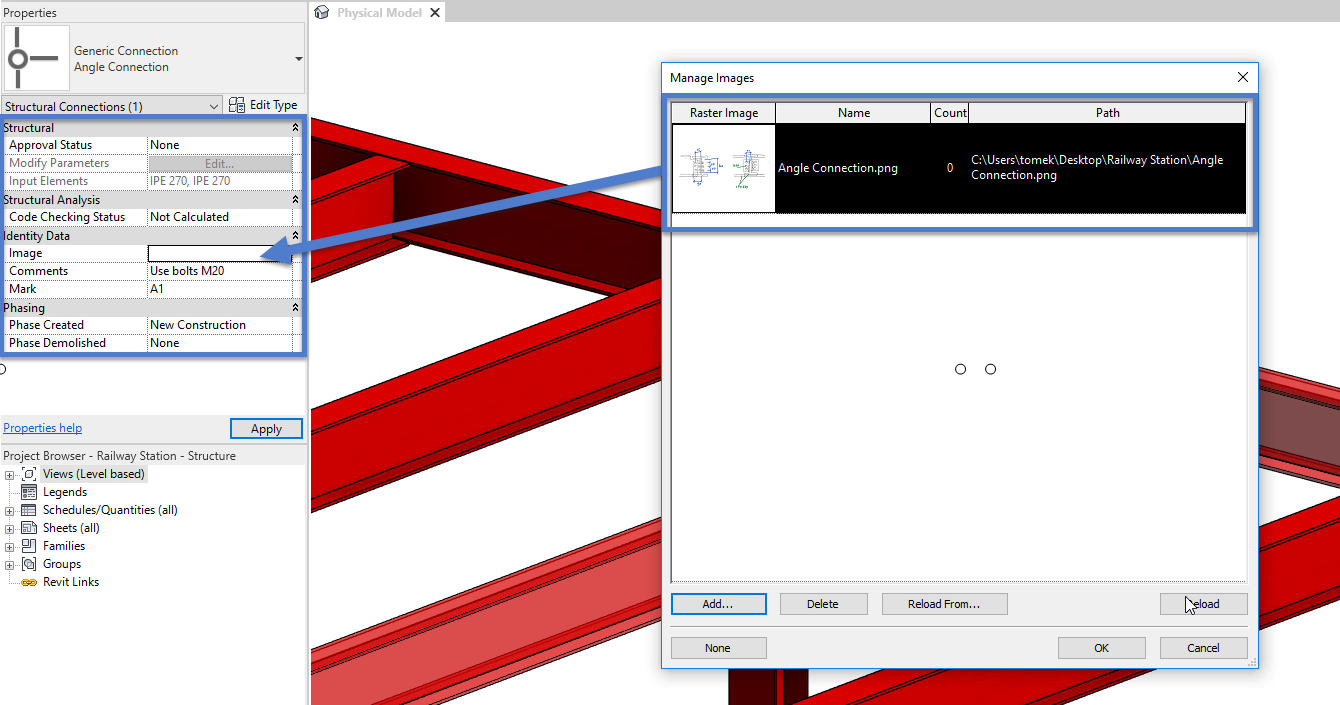

Beneath several parameters for schedules and tags, it also enables you to store pictures and link to further documentation about the connection, like connection requirements or design reports.

The symbolic connectors can be shown in drawings with color-based approval and/or code checking status parameters for an easier review and/or approval workflow.

If required, the connection between framing steel elements can be extended with detailed steel connections. Revit 2019 now provides higher levels of detail for modeling steel connections. The connections are comprised of new object types within Revit including bolts, shear studs, anchors, welds and plate work, and new cut and penetration object types. Users can also build custom connection details, in addition to using over 130 out-of-the-box parametric steel components.

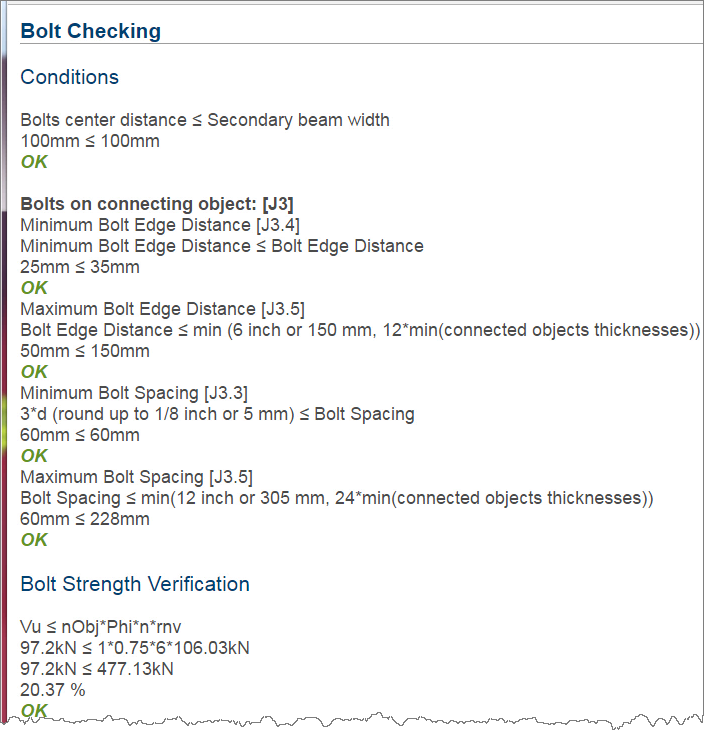

Also interesting is the ability to perform connection design.

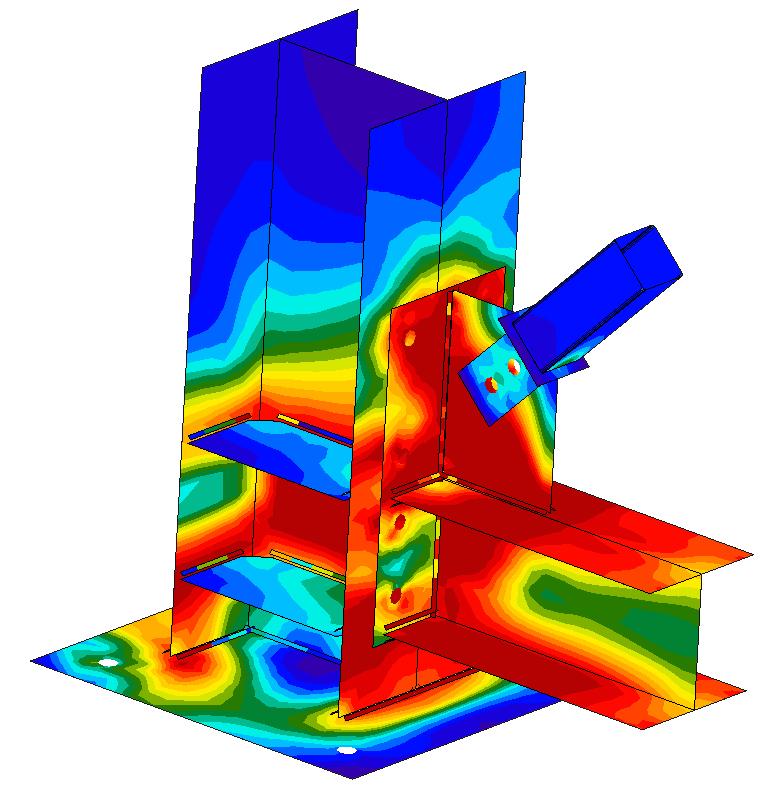

There is built-in connection design in Revit for standard connections (in the Part 1 I described how to get the internal forces needed for the code-checking), and integrations with third party connection design solutions, like IDEA Statica.

By connecting Revit steel connections to Statica, engineers can analyze and design the non-typical steel connections in the same BIM environment where they produce their design documents. The connection forces are also extracted from Revit’s analytical model database, which stores all forces collected by structural analysis solutions. This makes Revit a single source of truth for structural engineers to perform both the frame and connection design, as well as produce their documentation.

With detailed steel design capabilities in Revit, structural engineers can create new types of engineering documentation, perform BIM-based connection design, and produce more accurate bills of material (BOMs).

This streamlines work processes by enabling better collaboration between structural engineers, connection engineers, detailers, and fabricators in different locations. An effective bidding process is critical to the success of the structural business. Fabricators can benefit by receiving accurate quantities for bidding purposes through Revit design models. They can also eliminate waste in the shop and field by using the BIM environment to better coordinate their connection design to optimize for fabrication. Take a look below at the comparison of material take offs from Revit and Advance Steel.

Material Take Off from Revit:

Material Take Off from Advance Steel:

The BIM-centric solution allows users to design and detail with clash prevention in mind to reduce clashes both in the preconstruction and site execution project phases.

Detailers can benefit by better coordinating with engineers and contractors and managing the design changes. They can also extend their BIM-based services into preconstruction and reuse BIM-based model information directly from engineers to eliminate rework.

The link between Revit and Advance Steel software helps make the design to fabrication workflow smoother by facilitating the coordination of design models with detailed models. The bidirectional interoperability between the two products helps reduce the time needed to create and update design models, and helps to avoid potential errors resulting from manual coordination between conceptual design and documentation for steel detailing and fabrication.

Advance Steel software provides structural steel detailers, fabricators and engineers, with easy-to-use, comprehensive tools based on the familiar AutoCAD platform. These powerful 3D modeling tools support a BIM process to help accelerate more accurate detailing of structural elements, steel connections, and plates.

Advance Steel helps save valuable design and modeling time with its robust library of parametric steel connections that are ready to use right out of the box. Because the connections are parametric, changes to any structural member’s size will automatically adjust the connection’s size as well.

In addition to the intelligent structural objects, and parametric steel connections, you can help save valuable modeling time by using powerful wizards to more quickly generate straight and spiral stairs, straight and curved railings, and cage ladders and bring it back to Revit if needed.

Assemblies are automatically created in Advance Steel based on the field/bolt assignments in Revit’s steel connections.

Once your design is completed, Advance Steel offers a wide range of automated functions to create all the fabrication and general arrangement drawings.

Users can also create bill of materials using predefined and custom formats.

The software also automatically generates CNC (Computer Numeric Control) files (DSTV format) for workshop machines, such as welding robots, allowing the direct data transfer from the 3D model to fabrication.

Advance Steel is intuitive enough to inform the user in real time if documents such as drawings, bill-of-materials and CNC data require an update. Advance Steel offers the possibility to update the drawings with an integrated revision control including automatic revision clouds.

@tomekf

To access Revit, Robot Structural Analysis, Advance Steel, and more essential BIM tools, subscribe to the Architecture, Engineering & Construction Collection.

Steel Workflow from Early Concept to Fabrication using AEC Collection – Part 1