When the average engineer thinks of CFD (computational fluid dynamics), they think of many manufacturing applications: pumps, valves, electronics cooling, etc. At its foundation, CFD covers any thermal and fluids dynamic related matters. If you look around your room today, you’ll notice many applications that relate to heat transfer and fluid movement. For example, from my desk in my Florida home office, I observe the sunlight beaming through the windows, the air coming out of the vents, and even appliances generating heat.

In this blog, I’ll discuss a specific case study example where we will evaluate an overly hot room inside of our Denver facility. We can hypothesize many reasons why the room is hot – Is the air not circulating? Is there too much sunlight radiating through the windows? Is the room properly ventilated?

With Revit, we have a working model that we can use for analysis. We can leverage the integration between our modeling and simulation tools, and directly export our Revit model to Autodesk CFD, or export to Fusion 360 for additional model cleanup. During this process we may want to remove certain features that aren’t needed in the analysis or simplify volumes to provide faster run times.

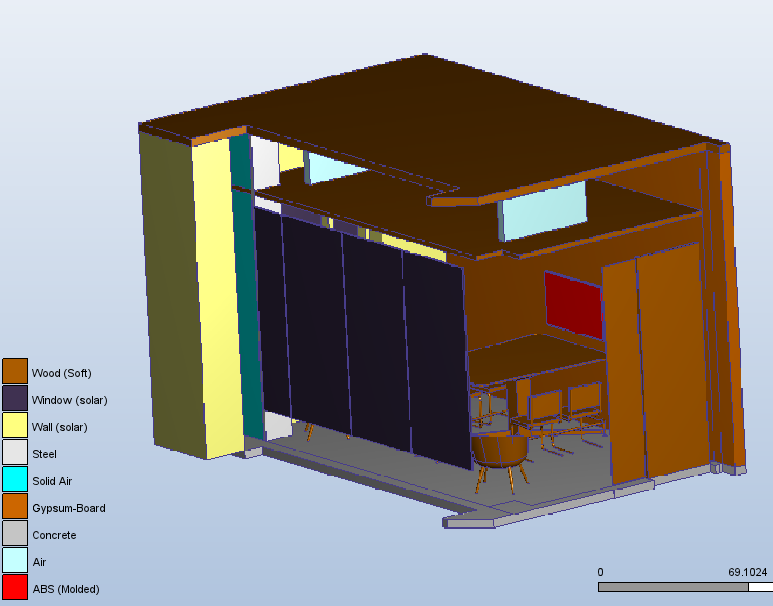

Once in CFD, we will define all the materials and input conditions for the model. For example, to define the materials, we can define the proper wood framework, cement, the drywall, insulation, the windows, and other bodies in the simulation. For the inputs, we can define the time of day and year for solar radiation, the ventilation, and inlet flow from the HVAC system, and any associated temperatures.

Isometric view of materials setup

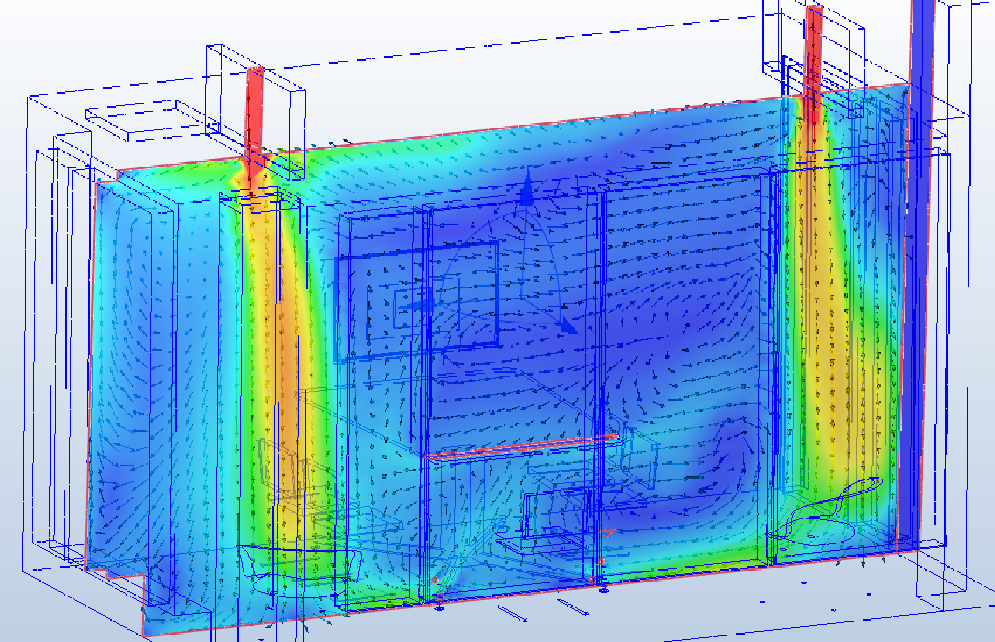

Once the CFD model has been setup and solved, we can then interpret the results of the simulation to provide design insight. We can test our original hypothesis to see what is making the room too hot. We can look for things such as stagnant airflow, in which we can move the vents or change the diffuser profiles.

In this example, we found that there was too much sunlight entering the room, which caused the room to heat up due to a lack of ventilation. This is a great example of why it is important to simulate your designs upfront and early in the process. When designing the room, we could have redesigned the location of the vents to make changes so that everyone in the room is comfortable.

Cut plane showing airflow in main room

Finally, in a world where visualizations are paramount, we can export our CFD results and look at them in augmented reality. This provides incredible insight for anyone involved in the process because you don’t need any engineering knowledge to look at airflow in augmented reality! Anyone can put on a headset and understand exactly how the air will move (in this example). Many customers come to me and ask for this technology for building inspectors and other stakeholders that need a high-level understanding of the dynamics.

CFD is a tool that can help us predict exactly how our designs will perform in the field. We can leverage this information to run Design of Experiments or make changes to give us an optimal and cost-effective design. Upfront simulation on this office could have driven towards more optimal ventilation to keep continuous airflow, allowing occupants in the room to be much more comfortable. It’s hard to analyze these types of problems without using a simulation code, which will give us insight into any model that hasn’t been physically built.

CFD has been used to help thousands of customers, and many of those in the AEC industry due to our direct integration with Revit. Visit our simulation hub for more information.