A trio of teams tackling vastly different design problems worked to find solutions with Autodesk’s Project Refinery generative design beta. Here’s what they discovered.

This summer, five teams from three continents traveled to Autodesk’s Toronto Technology Centre for a two-week Generative Design for AEC Intensive Residency. You can read more about the residency here, but the chief goals were to learn how to use generative design to approach everyday design problems, and to test Autodesk’s new generative design beta software, Project Refinery, against real-world design problems.

Each team came into the residency with a specific set of design questions, and they were often surprised by the number of different solutions they were able to uncover, the ability of the software to optimize those options, and the potential they saw for generative design to share the future of the AEC industry.

Here are the results from three of the residency teams:

Optimizing Reinforced Concrete

Hone Structures, born out of Marcos Silveira’s doctoral research, is a Brazil-based company that aims to develop a new approach to design and building processes for optimized reinforced concrete structures. Silveira and his team are attempting to incorporate 3D printing, automation, and generative design into this new approach, and Silveira says the Autodesk Generative Design for AEC residency was a great opportunity to explore potential workflows for the team.

Silveira, along with intern Gabriela Vivan, attempted to find ways to use generative design to optimize reinforced concrete around several variables – including cost, weight, materials use, fabrication time, and performance. “The first goal was to understand what parts we can take out from the original model, and still maintain the structural integrity,” Silveira says. “We’re taking concrete out, but at the same time, we must retain its capabilities and structural behavior. So, while we’re taking out concrete, we’re adding a lot of steel rebar. And we’re trying to find our sweet spot: how much concrete must we take out, and how much steel must go in in order to be more economical, faster to build with a 3D printing approach, lighter, and aesthetically pleasing.”

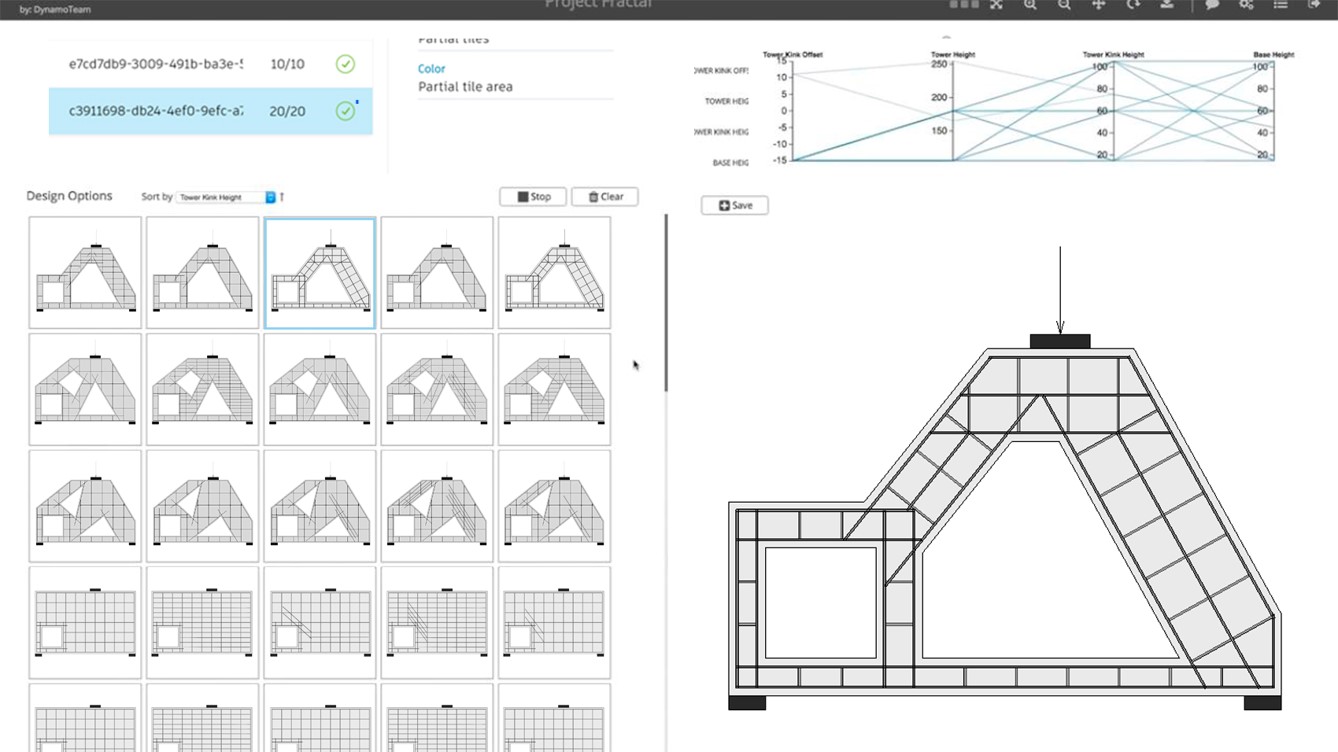

A screen capture of a Refinery study illustrating the various ‘macro’ forms of a concrete beam and the automated layout of rebar and ties within each iteration.

During the residency, the Hone Structures team discovered that their work will ultimately require the integration of several different design and computation tools, and their time working with Project Refinery and Dynamo helped give team members a better sense of how they can embrace generative design in their future work. “The residency helped us fix our path to our long-term goals,” says Vivan. “It sped up our project. If we had not had this residency, maybe a year in the future we would run into certain barriers. Now, as a result of the residency, we already know that those barriers are there, and we are working to avoid them.”

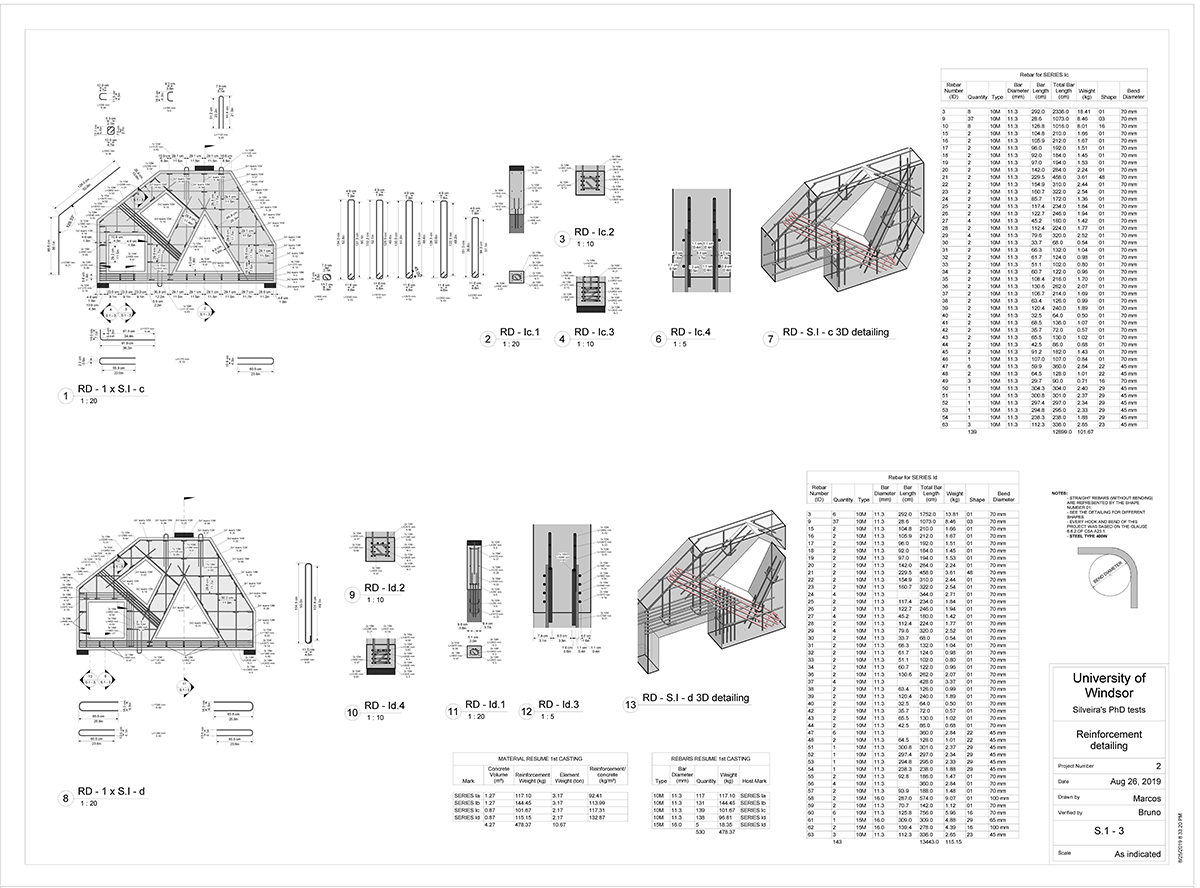

Rebar and tie detailing page made within Revit after a preferred candidate was generated and evaluated from Dynamo and Refinery.

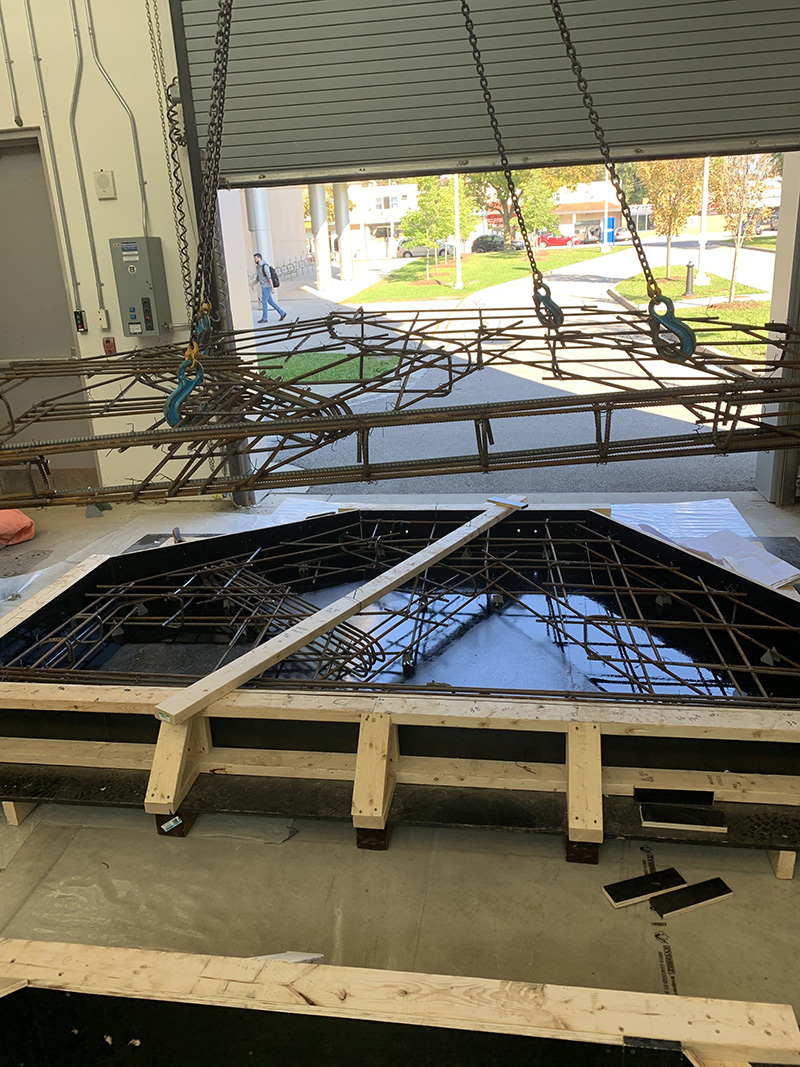

Photo taken from the University of Windsor (Ontario, Canada) where 1:1 fabrication tests of the geometry and rebar are being created for physical testing.

Master Planning

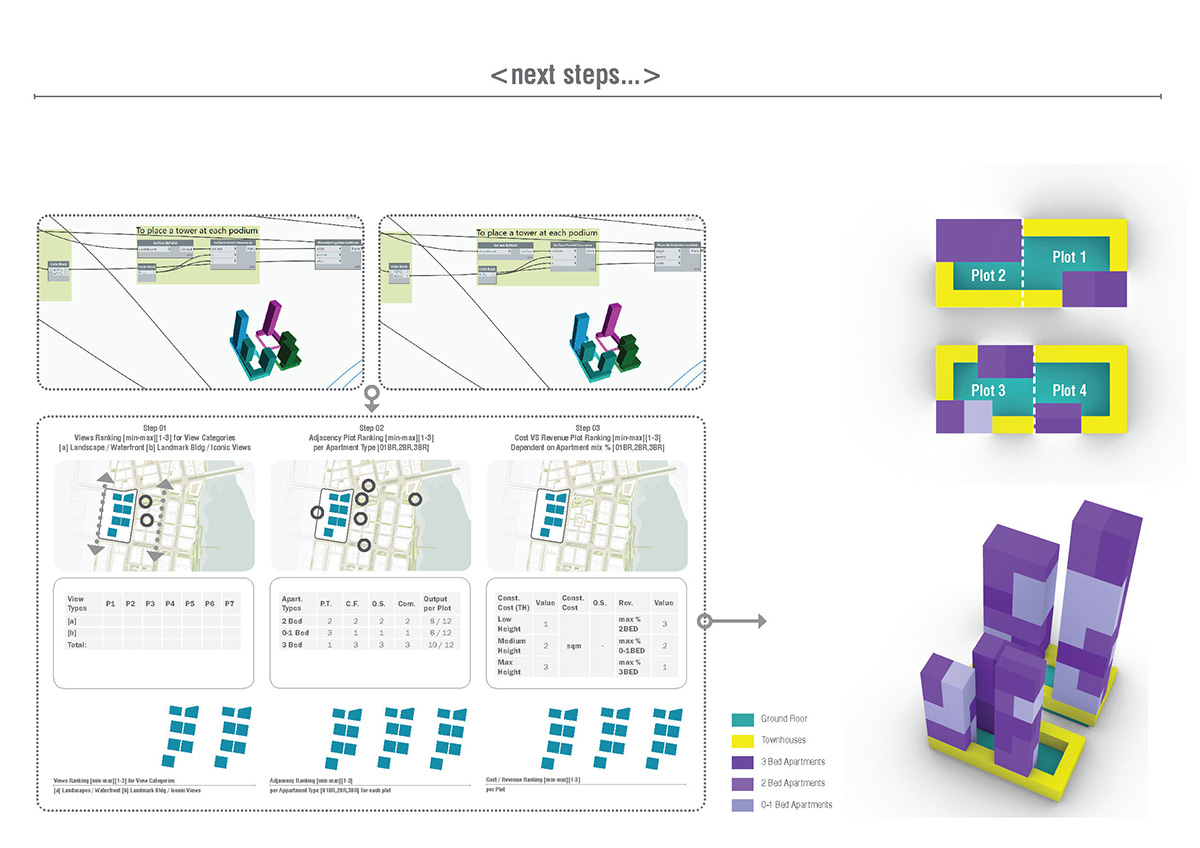

Parsons, a full-service firm of urban designers, planners, engineers, architects, landscape architects, consultants, and technical specialists, sent a design team to the residency to explore how generative design processes might help the firm to optimize master planning. During the residency, the Parsons team worked on the Reem Island Integrated Concept Master Plan, an approved Abu Dhabi project involving a total gross floor area of around 2.4 million square meters. The Parson’s team decided to focus their time at the residency on one aspect of this project – the Downtown West mix-use neighborhood.

The team’s objective was to maximize the design’s residential area for solar gain, primary views, and pedestrian circulation.

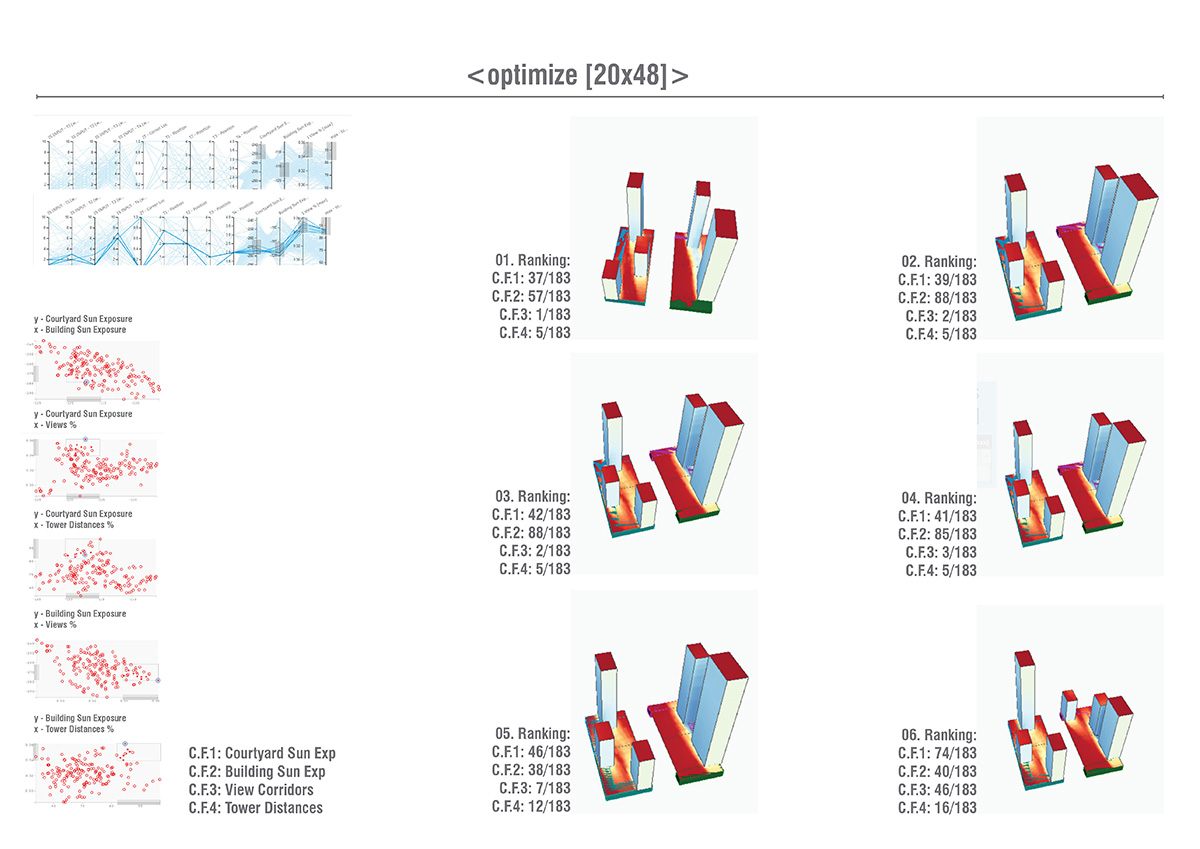

Composite image of results from a Refinery study where solar exposure on the block of towers and their shared courtyard is being analyzed in comparison to views, floor area, and constructbale height.

“Parsons has been a world leader on technology implementation in design, through adoption of digital and computational design procedures and tools that not only improve the quality of the delivered design but also reduce the design cycle” says Theofano Antonakou, an architect and urban designer with the firm. “Project Refinery can help Parsons towards this road. It combines the computers’ power for performing infinite calculations of multi-objective optimization studies in a very short time with the creativity, judgement and perception of the designer which is needed to set the initial design context, balance the criteria and weights of different design objectives, and ultimately select the best options based on the clients’ requirements.”

Indeed, by using Project Refinery, the Parsons team was looking to find solutions that would ideally place the additional residential gross floor area on the optimal locations according to parameters. Some of these were shading in the hot Abu Dhabi climate, placing three-bedroom residential units (which are more likely to house families than smaller units) near amenities like schools and parks, and preserving the original design intent.

Composite image of an experiment to further explore GD technology to assist in optimizing the allocation of specific bedroom types/units within the larger block layout.

“Project Refinery proved really useful,” Antonakou says. “It gave us a doorway to many possible solutions, but also to many new ways of thinking.” One of the greatest benefits of the residency, Antonakou adds, will be bringing that thinking back to Parsons. “As an experiment, the residency showed us how to create a more informed and scientific approach to design decisions. It’s then easier for our design team to work with clients to understand how a certain decision solution corresponds best to their needs and requirements.”

Preparing for Climate Change

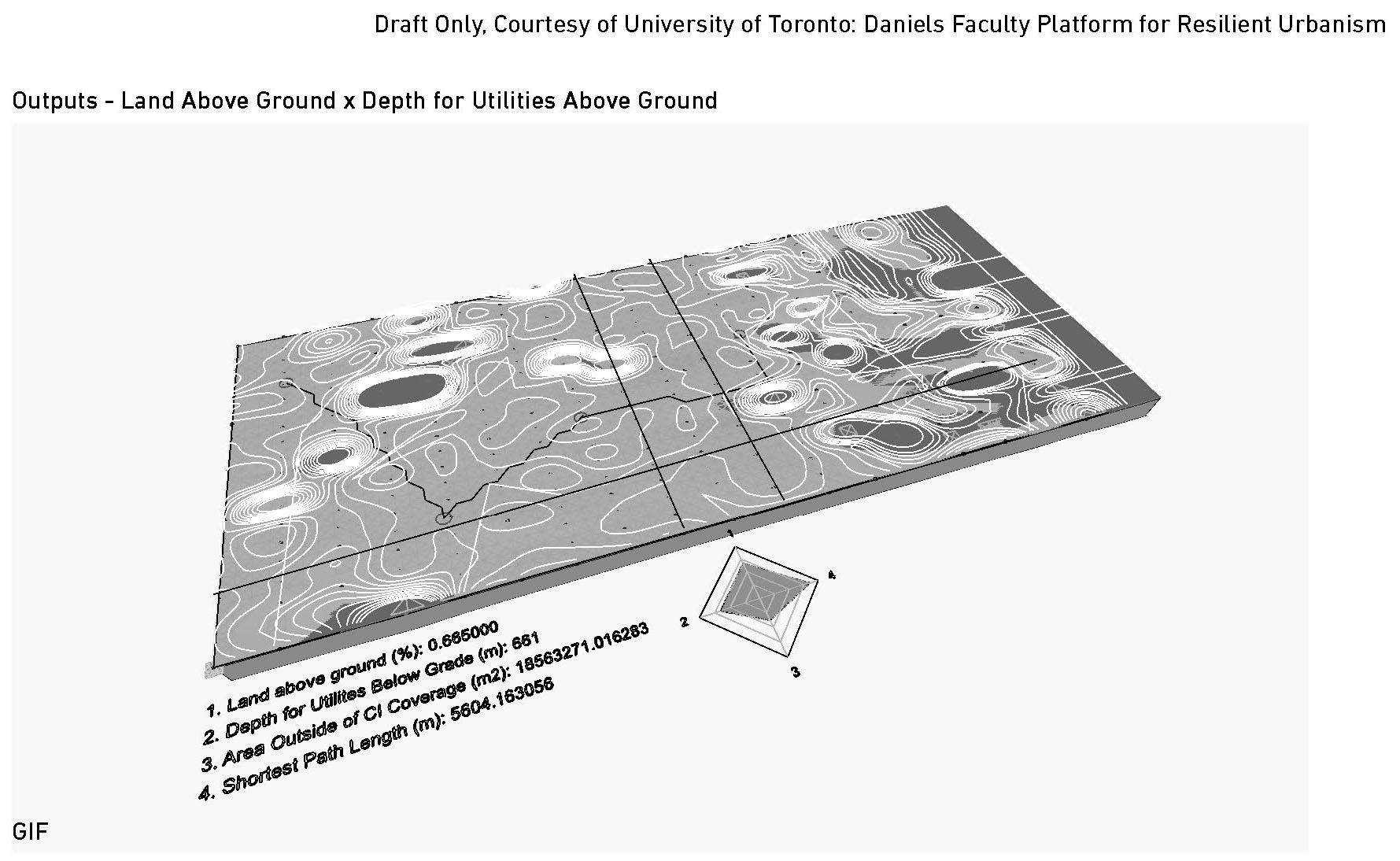

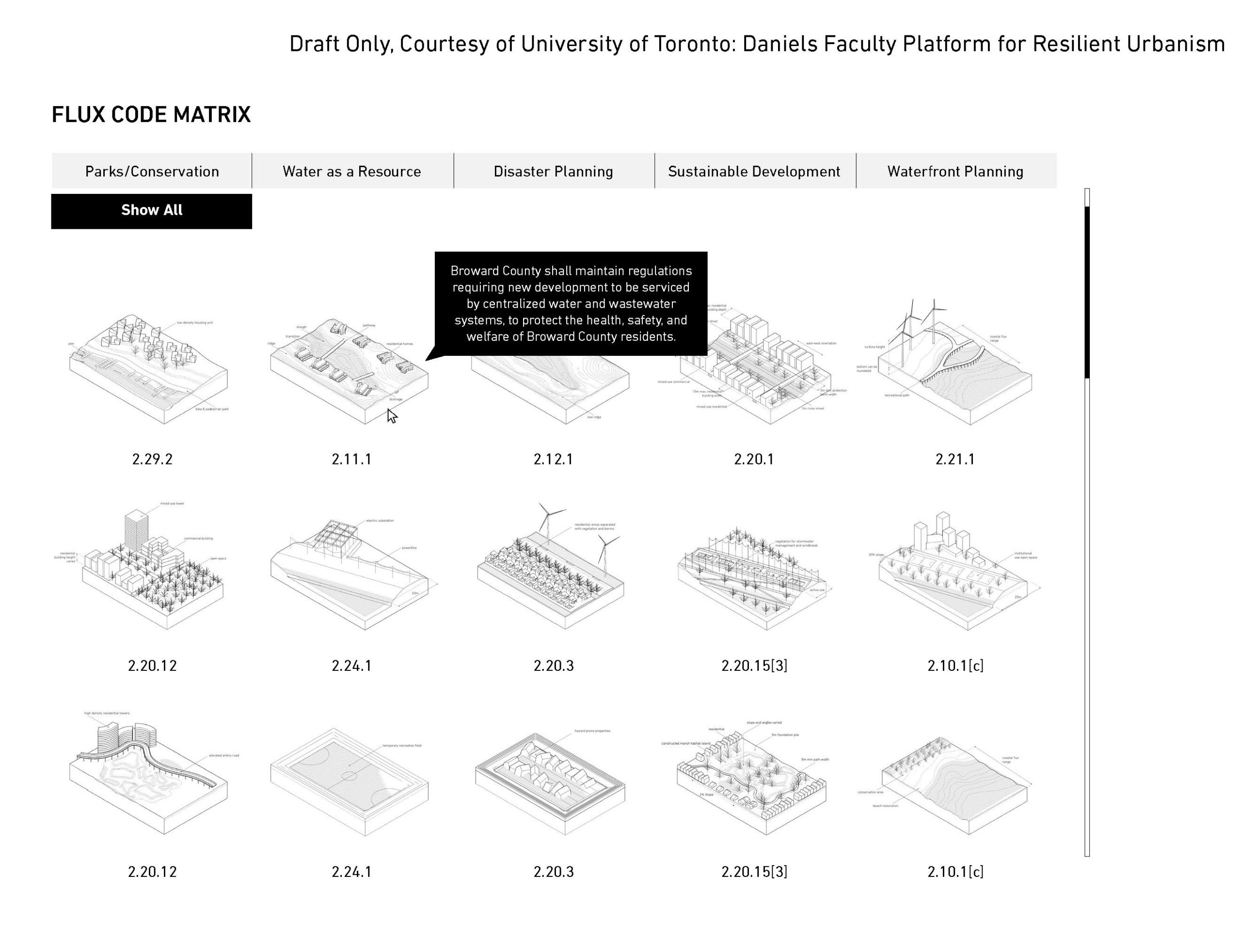

A research team from the University of Toronto is working with Broward County, Florida to analyze geospatial data and propose design variations to help the county prepare for and adapt to climate change and sea level rise. The team is looking not only at building design and traditional urban planning considerations, but also at how landforms could potentially be reshaped to minimize the impact of future flooding. “We had tons of geospatial data about sea levels, property parcels, density, and other geographical characteristics of the county,” says Isaac Seah, a research assistant with the team. “We wanted to understand how we can use that data to help guide some of the design variations, so we can bring that information back to policy makers to help them make better decisions with regard to planning around climate resilience.”

Screen capture of a generated terrain option and how well it scored on the 4-point radar graph (including metrics such as depth of utilities below grade and shortest path of travel on the terrain).

Seah says that researchers came into the residency thinking that the work would be a “simple process” of inputting their goals into Project Refinery and then evaluating the output from software’s algorithms. “There was a pivot in the way we thought,” Seah says. “The generative design process was really about taking big questions and then boiling them down to quantifiable metrics, looking at the performance of each design iteration, and evaluating them against these measurable goals. Once you have that information, you can rank the various design iterations and start grouping more optimal and less optimal solutions.”

Composite image illustrating how generated terrain and urban form could be detailed for programmatic use.

It was eye opening, Seah says, to see just how varied potential designs can get. He notes that Project Refinery allowed the research team to access millions of design iterations — an outcome that would, of course, be impossible through manual processes. “Taking a generative design approach with Project Refinery gave us a different way to think about design, and really helped us to think outside of the traditional design thinking box,” Seah says. “That approach is really powerful to take away from the residency.”

If you’re interested in getting started with generative design and the Project Refinery beta, we recommend watching this tutorial:

https://videos.autodesk.com/zencoder/content/dam/autodesk/www/videos/introduction-to-refinery.mp4