A few years ago, we started a series of blog posts highlighting the benefits of integrating the rebar detailing among the project stages that need to unfold in a BIM environment. We acknowledged since then that the reinforced concrete industry was lagging behind structural steel in terms of BIM adoption, and it is for this reason that we kept our focus and determination to make Revit the go-to platform for any structural engineer or detailer who live in the world of rebar.

One mission has been identified and it has been driving our roadmap ever since: help our customers reap the many benefits that working in Revit can bring for design-driven reinforcement modelling, detailing and instructions for fabrication and construction by transitioning them from CAD to BIM. But we know that, as aspirational and motivational this may sound, the details from behind the bells and whistles are what make anyone take such a hard decision: to migrate from their current rebar detailing software to Revit. In the world of rebar detailing, productivity is king. Speed of placing all the bars, dimensions, tags, creating hundreds or thousands of tidy drawing sheets, these are the things that matter. I say this is a hard decision because of two main reasons. On one hand, CAD workflows are more abstract, whereas BIM is all about the reality, making it difficult to encapsulate in drawings the information in a way that matches CAD practices. On the other hand, many people are afraid of change, not knowing from start how well they would adapt to Revit, but as soon as they realize that, besides the matching detailing speed, they also benefit from always up-to-date interdisciplinary model coordination and various team collaboration solutions, they realize their decision was the right one.

Therefore, we talked to many of our customers, who not so long ago were still working in a 2D environment. Some of them have been kind enough to share their stories and extensive feedback using Revit. Their workflow specifics have also been accurately mapped out with the help of GRAITEC, one of our multiple trusted technology partners.

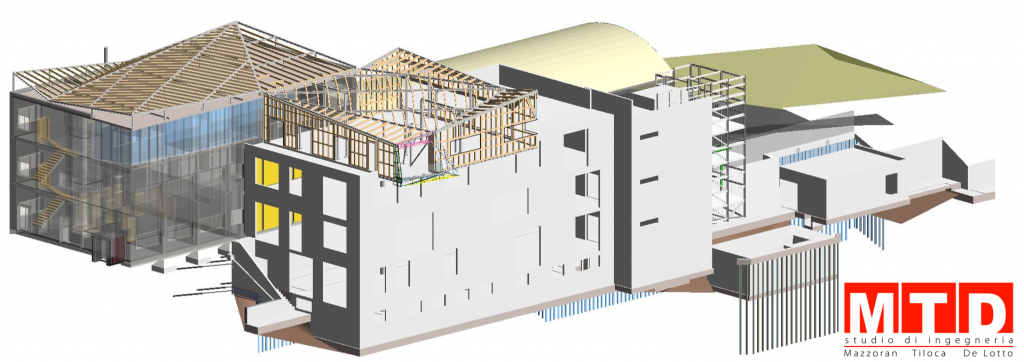

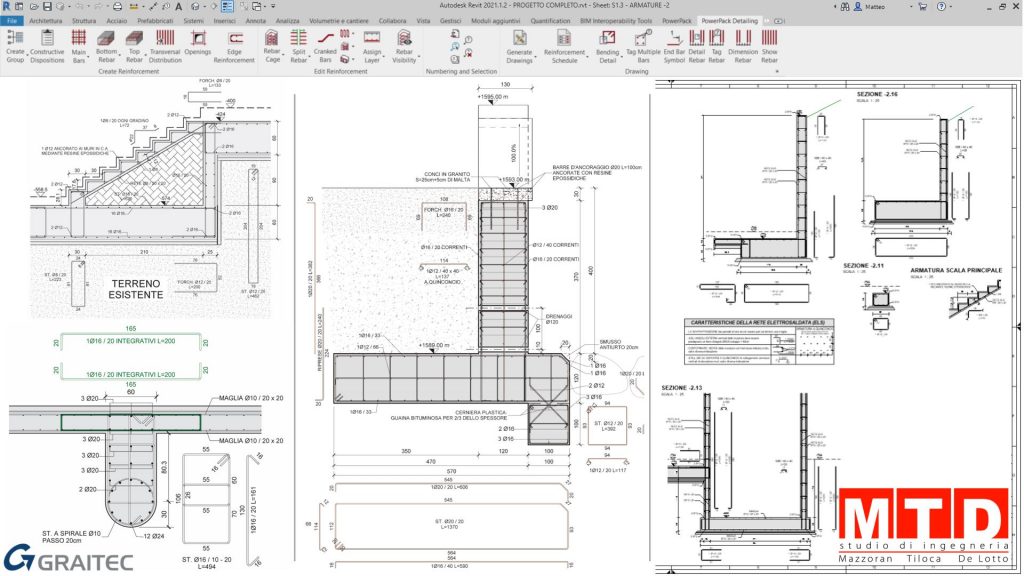

MTD Studio di Ingegneria

Studio Associato di Ingegneria Mazzoran Tiloca De Lotto is an Italian design and consultancy firm, engaged in the civil, commercial, industrial and infrastructure fields for thirty years, with a portfolio of over 1,800 projects. Their clients are architectural firms, building technicians, construction companies, manufacturing companies, commercial firms, public bodies, investment companies.

For rebar detailing, they used to work with AutoCAD, but decided to migrate to Revit and GRAITEC Advance PowerPack for Revit Premium, for an increased production speed of reinforcement plans, improved accuracy of placing and adjusting the rebar whenever something changed, faster set-up of each new project and less coordination errors, all of these leading to financial savings for the firm. “As far as the reinforcement of the elements in BIM is concerned, it was a winning choice because the errors are reduced to a minimum and the speed of creating the bar bending schedules and making any correction of errors is very fast. I can tell you with certainty that when designing a complex building, with Revit, the time is halved and therefore the production is doubled.” says Matteo Scussel, BIM Specialist at MTD Studio di Ingegneria.

One of the latest projects where Revit and the GRAITEC PowerPack have been used is the extension of a building for the production of titanium eyewear, located in Belluno, Italy, requiring concrete, steel and wood building works. The main challenge was to model all the bars from all the elements, knowing there would be many changes to follow on such a complex project, so the revisions time needed to be kept at a minimum.

GRAITEC’s tools allowed them to efficiently detail the reinforcement, create bar bending details and schedules and automatically generate batches of drawing sheets according to the Italian way of practice. In the future, they plan to improve the multi-disciplinary coordination, by asking all other firms collaborating on projects to use Revit’s work-sharing capabilities.

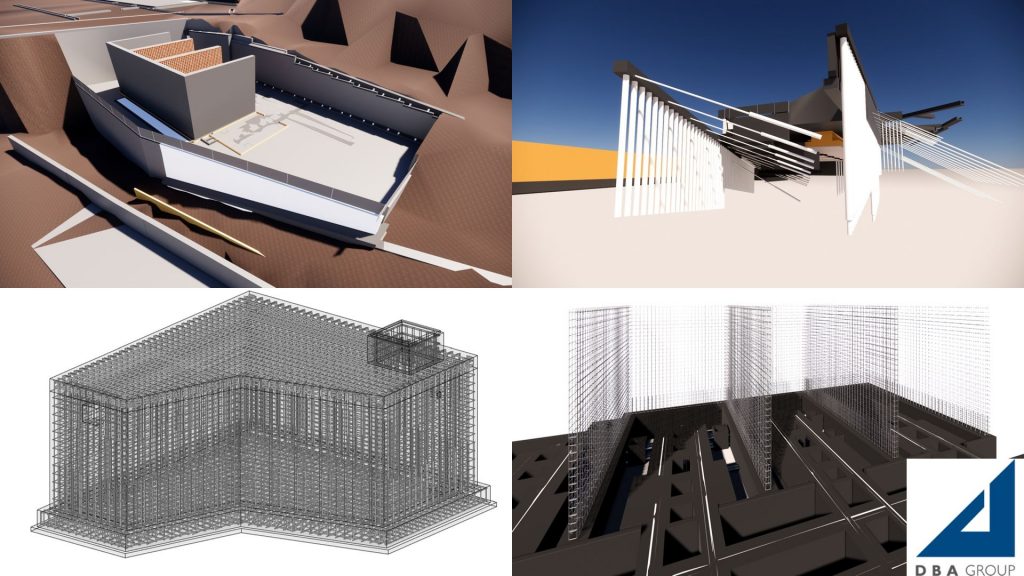

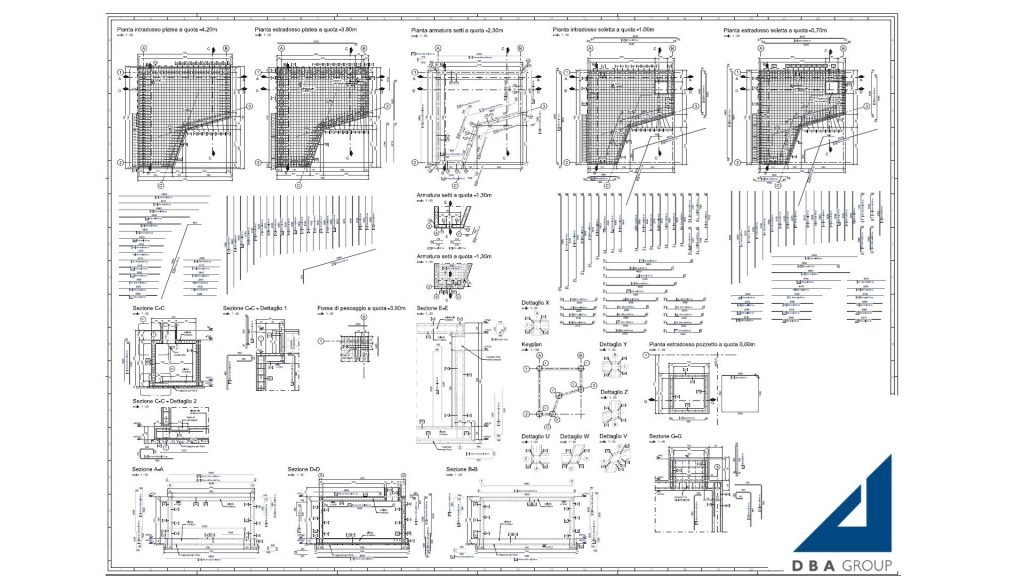

DBA Group

DBA Group is an independent holding company specialized in the provision of Consulting, Architecture, Engineering, Project Management and IT&C solutions focused on lifecycle management for buildings and mission-critical infrastructure. The Group operates through 14 offices in Italy and 10 abroad, employing over 650 people and helping more than 400 clients.

Founded 29 years ago, they have always been keen on how technology can make them more competitive to expand into new markets. Revit and GRAITEC’s Advance PowerPack Premium Concrete Package grew constantly over the past couple of years and so did their clients’ demands for faster project deliveries and swifter responses to design changes, which made it clear to DBA that the migration from CAD to Revit was the obvious shift to make. They were efficient with CAD and so wanted to make sure their use of Revit delivered better productivity while bringing the benefits of BIM

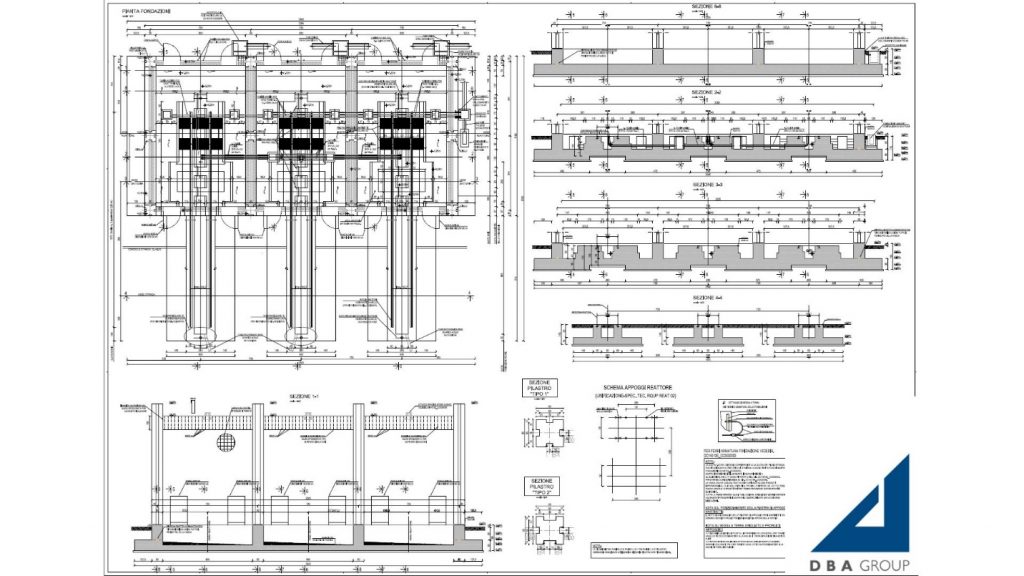

One project where using BIM proved to be highly beneficial is the expansion and modernization of an electrical Power Plant located in the north of Italy on the border with Austria (Interconnector Austria Italy). The project scope included installing three new 220 kV single phase reactors, plus a reserve reactor of 132 kV separated by 120 minutes fire-resisting walls. The area affected by the works is located partly inside the existing station and partly in the surrounding area. The extension of the electricity station, including road upgrading works, is a total area of 2700 sqm. The entire expansion area will be delimited by a reinforced concrete retaining wall with a height above ground of approximately 1 m. In detail, this project includes: terrain containment works, underground works and reinforced concrete foundations and fire-resistant walls, including rebar detailing for all these elements. According to Simone di Biase, BIM Manager at DBA Pro S.p.A., “this latter task is the most relevant in the construction phase for this kind of project. Adjusting is easier because you can check directly in a 3D view. And in this kind of project it’s a great advantage, because you can view all the modeled objects and coordinate with the team. The internal team coordination uses the modeled rebar, exported in RVT or IFC formats, in Navisworks, where we can make all the needed checks. The most important benefit is that, in case of project variations, we can update rebar detailing, sheets, and quantity take offs more efficiently than in traditional projects. Our customer is very interested in this type of solution because it allows him to test multiple project solutions to find the most suitable one, both technically and economically.”

The solution was identified in GRAITEC’s Advance PowerPack for Revit, with specific commands that “allow us to manage the modelling of all the reinforcing bars of complex projects and to optimize the layout of structural sheets for the construction phase, even in the cases of project changes or variations, with automatic update of both schedules and drawing sheets.”, as Simone di Biase mentions. The main benefits using Revit are increased control over 3D objects and rebar, 30-35% less time needed to produce the reinforcement sheets, especially in the case of project variations, compared to the CAD workflow, and increased output quality, both in terms of graphics and sheer amount of information that can be extracted directly from the BIM models.

Both these stories talk about how many benefits switching from a 2D software to Revit bring for any reinforced concrete structure. While there may be a perception that BIM is really needed only on large scale projects it’s clear that this needs to be reconsidered, as the past few years have brought to us a totally new paradigm where project success hinges on efficiency and revisions accuracy coexisting in an interconnected environment. An environment where every project stakeholder that wants to see, can see at any given moment what the project status is, and sleep comfortably at night knowing that “nobody accidentally forgot to stretch those 55 bars by 15 cm, because the architect decided that the slab at 2nd floor should actually go a bit over the edge of the columns.” This is one of the cases that I faced when detailing some bars and I’m sure many of you heard or lived similar stories.

So, if you can do with Revit everything that you need to do with a 2D detailing software, and also get lots of extra benefits, what are you waiting for in making the switch?