Revit 2022 has some practical and useful new features for MEP. In it’s totality, documentation is the word of the day for Revit 2022, with all major disciplines getting a big shipment of enhancements to schedules, tags, and annotations. The aim is more efficient tools for producing project deliverables and productivity boost for architects and engineers. The focus on documentation comes from a great deal of user feedback on Revit Ideas — more on that in a minute.

Mechanical systems are in focus, too, with enhancements to Systems Analysis for early-stage design, and additions for detailers with an improved design to fabrication workflow. Let’s start there with what’s new for Systems Analysis.

Systems Analysis Additions and Enhancements

The big addition to Revit 2022 for Mechanical Systems Design and Analysis is the new HVAC Loads and Sizing Report. This represents several improvements over the previous, default EnergyPlus output report that was provided by Systems Analysis since it was released in Revit 2020.1

New HVAC Loads and Sizing Report in Revit 2022

This new and improved report provides key information on Zone Loads, System Loads and Psychrometrics all in one place. This breakdown should be relatively familiar to most Mechanical/HVAC engineers as it follows a pattern that’s similar to many 3rd party analysis tools used for this purpose. While the default EnergyPlus output met many of the requirements it wasn’t easy to navigate; the new loads and sizing report is more intuitive and comprehensive in Revit 2022.

One feature of Systems Analysis in Revit 2022 is if no Analytical System is defined in the model (i.e. Zone Equipment, Air and Water Loops), the report populates only Zone Loads where the analysis assumes systems to be ‘ideal’. This is useful for very early stages or basic room/space loads. System Loads and Psychometrics will be populated once an Analytical System has been defined and will be specific to that system/plant configuration..

This new release offers support for both Metric and Imperial units, and the report will default to your Revit project settings, but is easily changed within the report. Furthermore, the report has been localized to work in all the languages that Revit supports.

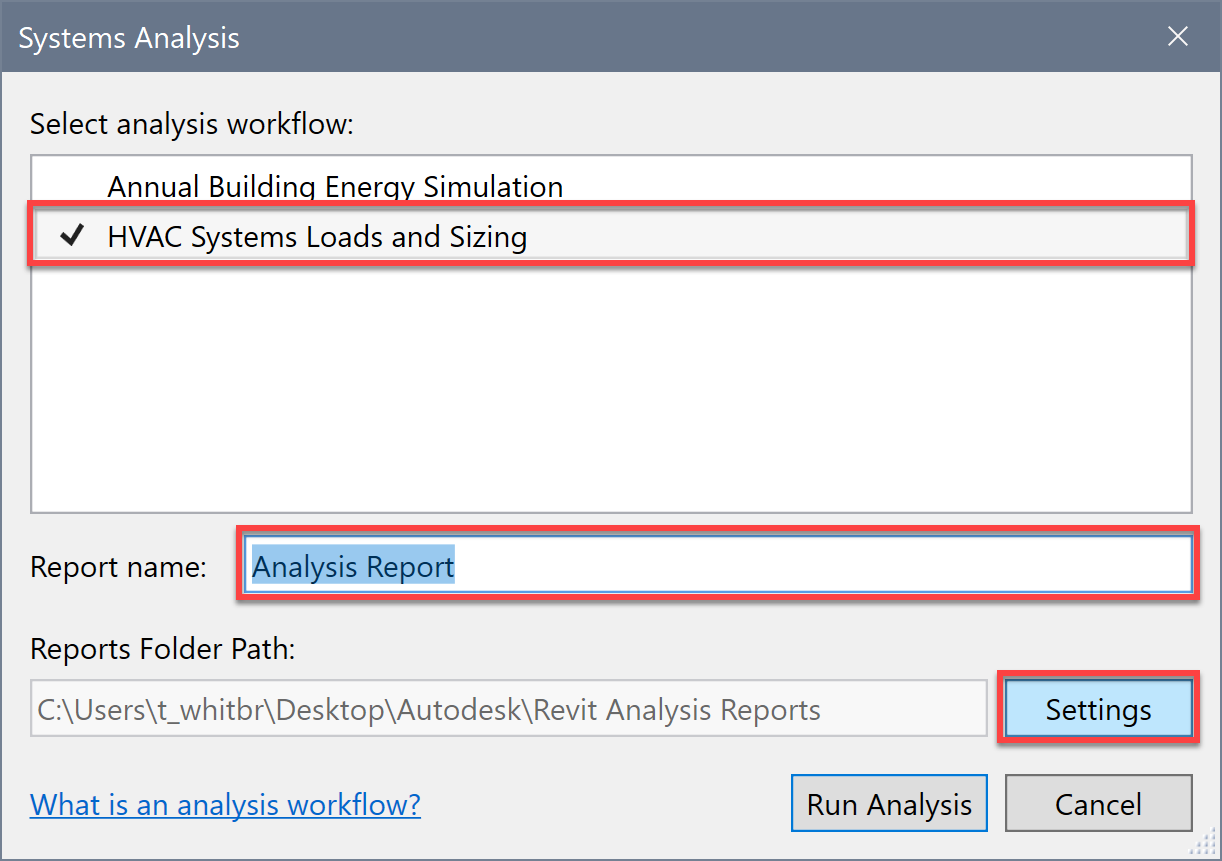

To generate this report (first create an analytical model – more on that below) then simply select the ‘‘HVAC Loads and Sizing’ workflow from the Systems Analysis ribbon icon.

The Systems Analysis Icon on the Analyze Ribbon

![]()

The HVAC Systems Loads and Sizing Workflow

Note that the Systems Analysis dialog allows you to specify a name for the report and open the energy settings dialog to change the location where the report data can be saved separately (as html and json). Then ‘Run Analysis’ will run OpenStudio and EnergyPlus as a background process in Revit so you can continue to work. Once complete the report can be found in the Project Browser under Reports.

The Analysis Report in the Project Browser

Of course, as with the rest of Systems Analysis, being built using the OpenStudio SDK and EnergyPlus the analysis itself and the report is very open and extensible. The report specifically uses the OpenStudio Results Measure so advanced users will be able to customize it to suit unique project, office or companywide needs.

We would like to give a big thanks and kudos here to the DOE and NREL for developing the EnergyPlus and OpenStudio framework to support the development of more integrated modeling and analysis workflows in BIM.

Finally, if you wish to run a Systems Analysis in Revit (or in a 3rd party tool) you need to create an Analytical Model (or export gbXML). There are improvements in this regard, with simplified and consolidated mode selection for creating, viewing and exporting Analytical Models. Under the Revit Energy Settings dialog, the ‘Use Conceptual Mass and/or Buildings Elements’ mode now includes the option to ‘Use Rooms or Spaces’, a capability previously only available via the File Export gbXML menu. Now, Analytical Spaces and Surfaces generated from any of these modes can be viewed and checked in any Revit view.

Energy Settings Modes now contain the ‘Use Rooms or Spaces’ option

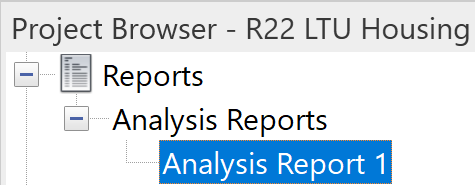

Each of these modes have different pros and cons. For the concept/schematic stage of whole building energy analysis, each mode fits to different ways of translating architectural models / elements into Analytical Spaces through Systems Analysis, and in Autodesk Insight.

If you are new to Systems Analysis, then it is worth checking out these two AU classes (one introduction, one advanced). Also if you’d like to see these tools in action check out the recording or a recent webinar that shows their use from design through to detailing for a real project.

AU Class Recording – Revit Systems Analysis Features and Framework – An Introduction

AU Class Recording Revit Systems Analysis Features and Framework – Creating Custom Workflows

AEC Collection Essentials: MEP Workflows

Revit Energy Analytical Model Modes Spanning Concept to Detailed Design Stages

Improvements to Systems Analysis serve early-stage design, while advances in the documentation toolsets are advancing modeling and deliverable production. What about for the detailers putting the finishing touches on a model? Revit 2022 offers improvements in design to fabrication workflows, too.

MEP Fabrication Modeling in Revit

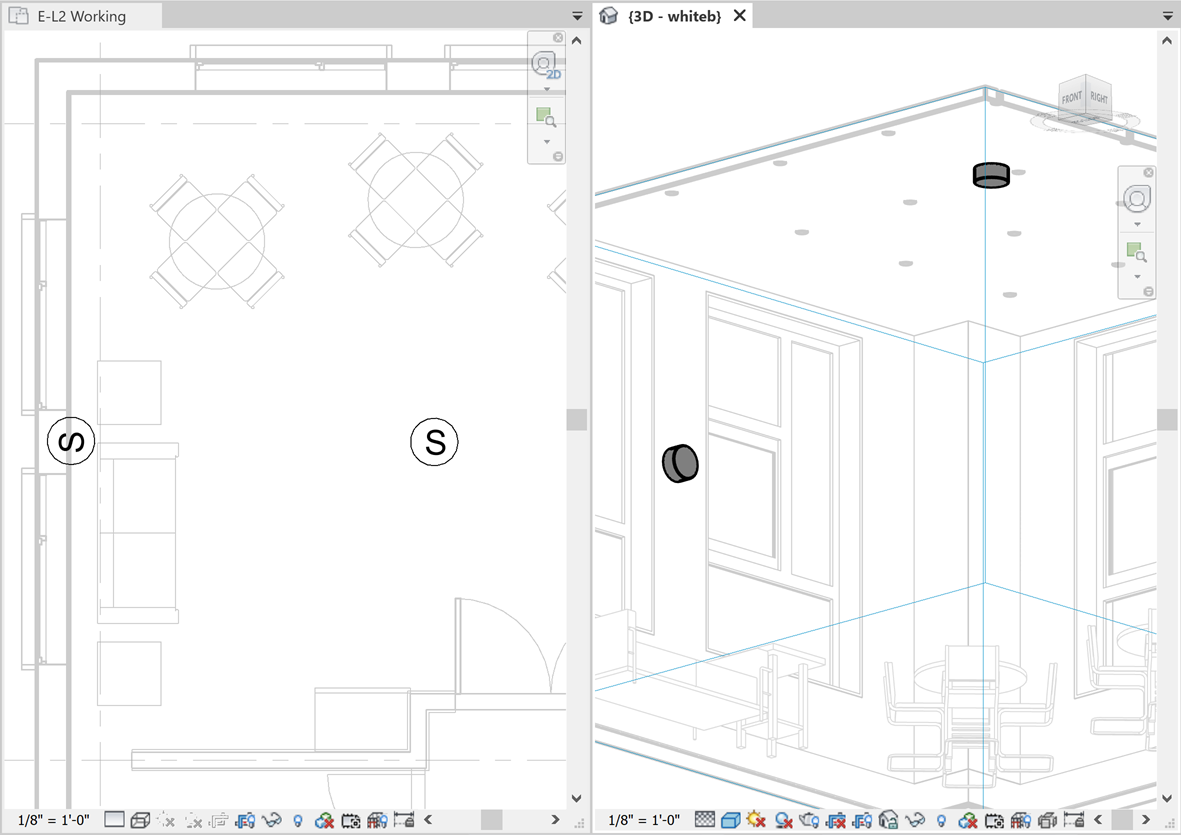

For mechanical detailers using fabrication ductwork and pipework, we’ve made a number of improvements to the in Revit modeling experience. There are improvements to the Design to Fabrication feature, the configuration reload process, and some in-canvas convenience improvements. The most significant change is a complete overhaul of the Design to Fabrication feature. Previously, this was the only functionality in Revit using the Design Line logic from CADmep/ESTmep. In order to have more consistency in behavior across Revit layout tools such as Quick Connect, Route and Fill, and Trim/Extend, we’ve removed the dependency on Design Line (and thus Button Codes).

Functionally, you will notice better results from Design to Fabrication. Most notably, off-center taps and eccentric reducers/transitions will now successfully convert, resulting in less manual cleanup after conversion from design elements. We also retain connectivity in more scenarios, for example, we now maintain connections to flex duct, making further edits/refinements a bit easier.

Design to Fabrication Improvements in Revit 2022

In prior releases, if you wanted to define a specific Fabrication part to be substituted for a given Revit Family, you had to make these mappings in the Fabrication Database as “button mappings” in CADmep, ESTmep, or CAMduct.. a process that was error prone (having to enter the names exactly), and was also challenging in that each design firm you work with likely had different families they were providing in their models.

In this release of Revit, we have a more dynamic solution, allowing you to make these mappings as you are going through the conversion process. The mappings you make as you are using the Design to Fabrication tool are specific to the service you are working with, providing flexibility in the event you use different services for different systems, each requiring, for example, different valves or other accessories, even if a family is applied generically.

Revit MEP Fabrication Inline Parts Mapping Conversion

Note: The mappings are only remembered during the session, as they are not stored with the project. The mappings will reset if you reload the configuration.

You’ll also note that there is no longer a ‘Select Service’ dialog that appears when using the tool. Instead, the current service is used, which you can change if needed while using the command. While using the command, you can make other changes before committing to the conversion, for example, changing round elements to rectangular (or vice versa), as well as overriding the size.

Another improvement that should be more transparent is related to the Reload Configuration process. We’ve made optimizations to reduce the number of elements checked out in a work-sharing environment, which generally results in an overall reduction to the amount of time it takes to run the process (our tests indicate 30-50% faster).

Note: We still recommend that prior to having one user reload the configuration, you have all other users save to central, and close the model. Once the configuration is reloaded, other users can open the model, and reload latest to get the changes.

As part of the optimizations of Reload Configuration, we’ve also resolved known issues related to disconnects and elements (typically couplings/flanges) that would be removed on occasion. This was happening for a variety of reasons, such as slight misalignments between parts and different states of exclusions when resolving updated/replaced elements.

The last set of improvements are more quality of life changes, simplifying some in canvas editing of fabrication elements when making connections in the model. Design parts have always had functionality that allowed making connections and adding fittings simply by dragging parts together. For example, dragging perpendicular elements together at an elbow, or into a tee/tap. This same set of convenient interactions is now possible with the fabrication elements.

In addition to these Revit improvements, note that we have also made a number of bug fixes to CADmep, ESTmep, and CAMduct in support of Revit based workflows. Our primary focus on these products is related to improving the behavior of patterns to minimize manual effort related to sheet metal fabrication in CAMduct. A few such examples are improvements to ensuring that holes for branches are properly positioned on decoiled straights. This helps with shop automation and reduces the amount of labor required. Another improvement is related to shoe tap for branches (pattern 7) had a problem wherein the damper hole was not burning in the proper position. Check out the release notes here for the full list.

Lastly, with all these steps forward, we want to let you know about a step back. The RME to FAB add-in is unfortunately not included in the CADmep installer as it has been in prior releases. This was an oversight in a major change from one installer technology to another. The installer will be available through Autodesk Desktop Application and Autodesk Account within a few weeks.

RME to FAB Add-in Ribbon

General MEP Improvements and your ideas

Finally, the productivity and efficiency upgrades with Revit 2022 are worth a mention, as include some very highly voted requests on Revit Ideas that serve architects and engineers of all stripes.

The first is related to one of the most voted MEP specific Revit Ideas. For this release, we’ve added Maintain Annotation Orientation support to several additional categories:

- Electrical Equipment

- Generic Model

- Lighting Fixtures

- Mechanical Equipment

- Plumbing Fixtures

- Specialty Equipment

Additionally, we improved the behavior of shared nested families. In prior releases, such shared nested families would not show their annotation symbol, but that has now been resolved.

Shared Nested Family Annotation Symbol

The next improvement is related to Panel Schedule Templates. There are a couple of settings in the panel schedule template options that imply that you should be able to use the same template for various panel configurations. Namely, under General Settings the “Number of slots shown” option, and in Circuit Table options “For panels other than three phase”, seemingly, you should be able to setup one template that flexibly adapts to different schedule lengths and poles/phases. However, in practice this didn’t work. Chiefly, because the cell shading would not adjust as needed. As a result, users would need to maintain templates for each phase configuration (1-, 2-, or 3-pole panels). Additionally, one would need to make sure to use the template appropriate for each panel configuration.

For this release, we’ve added an option on the Circuit Table settings for “Auto-shading for displaying load”. This allows the shading of the circuit table to dynamically adjust to the conditions of the panel, reducing the number of templates you need to maintain, and reducing the possibility that someone will apply the wrong template based on the panel poles configuration. When the “Show but disable column for unused phases” option is selected, the cells in disabled columns are all shaded. Additionally, if a schedule is configured to show more rows than the panel’s “Max Number of Single Pole Breakers”, the cells for those rows will also be shaded. Lastly, the cells will automatically shade based on which cells are applicable for a given row and phase.

Auto-shading for Two-column Panel Schedules in Revit 2022

Another last minor improvement to electrical functionality is the addition of support for project parameters when defining electrical circuit naming schemes.

There was a minor change to pinned element behavior. In prior releases, one could move a pinned element by dragging the connector. We’ve now made it such that pinned elements can’t be moved in that way (this was actually incorporated into the 2021.1 release).

Another improvement to MEP generally is related to the Show Disconnects functionality on the Check Systems panel of the Analyze ribbon. In testing scenarios that took 5-8 minutes in prior releases now takes 10-30 seconds to toggle on or off.. a model that took 23 minutes now takes about 1 minute.

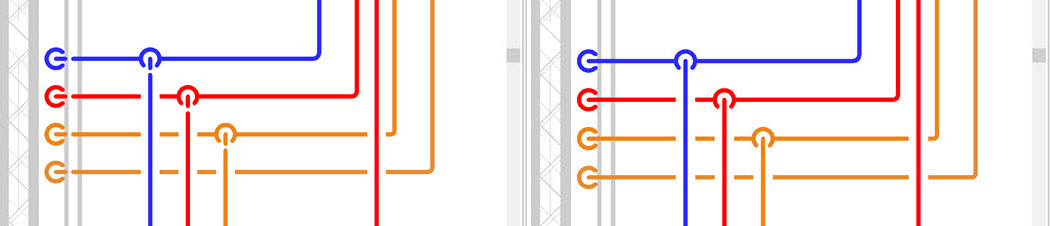

Lastly, there were a number of improvements to tags and rise/drop scenarios. Namely:

- Tags on vertical pipes (in plan) were failing to report system name & abbreviation.

- Rise symbol was failing to show in certain situations

- Single line graphics on pipes have been improved (see image below)

- Setup / Set Down tag was reporting ? (see image below)

Single line improvement, prior releases shown on left, 2022 on right.

Set down tag showing expected value in Revit 2022.

There were a number of additional fixes for things reported through our product support channel. Please check out the release notes for the full list.

To sum it up, Revit 2022 is a relevant release for MEP engineers, full of productivity increasing features and enhancements that can move your everyday project work along. For more resources, check out the links below, including the link to the Revit Public Roadmap to see where we’re going next.

Links to additional release content to check out:

- BIM Manager’s Corner with Aaron Maller of Parallax Team

- Changes to Revit Deployments for 2022 with New Autodesk Installer

- What’s New in Revit 2022 YouTube playlist

- Revit 2022 release notes for performance upgrades, bug fixes, and more.

- What’s New in Revit 2022 on the AKN for more information on new features and workflows.

- Set a reminder for the Revit Public Roadmap Live Ask Me Anything on May 4, 2021

Join the Revit Community:

- Have a question about Revit? Take it to the Revit Forum and let the community of Revit users help you sort it out.

- Have an idea for making Revit better? Go to Revit Ideas to find, post, and vote for the things you want to see in new versions of Revit.

- Want to see what’s coming in Revit before it is released? Sign up for Revit Preview access and give us feedback on new features in Revit before they are released.

- Want to have a say in the future of Revit and other Autodesk products? Join the AutodeskProduct Research community and lend your perspective to help us build the products you need.