Unlike any of my previous articles, I will start this one based on a personal story, from when I was working as a structural engineer. I used to design all types of structures, made of reinforced concrete, masonry, timber, but many of them made of steel. They were either medium-size office buildings or typical low-rise commercial or industrial structures. These were one-person jobs, which meant I was responsible for all stages, taking over the sketches from the architect, proposing a structural layout, analyzing it and fine-tuning the sizes of the main steel elements, so that eventually I could propose accurate steel connections.

Guess which stage took me the most? If you are a structural engineer, probably your answer would lean towards the last step from my enumeration. I admit finding the optimal sizes for the structural elements is not trivial either, but it was so time consuming to come up with good connections for every new design. And to make my story sound even more classical, I was often under time pressure, as many of my designs were needed for submitting bids, my colleagues from the architecture team kept tweaking their designs and the fabricators we were collaborating with were suddenly realizing that for that project they could offer better prices if we were to use fewer high-strength bolts, instead of more standard grade ones, which meant I needed to quickly react again and again. Still, we needed to win tenders, so I was trying to impose myself some rules, to standardize how I design and which connections should I propose across similar scenarios. But that was hard. Imagine the tools that were out there about a decade ago: disconnected across design and modelling phases, worksharing was in its early days, and there was no proper BIM solution that could have embedded all the details that engineers must handle in their minds.

Memories like this motivated me to believe so much on how this new workflow, that we are enabling with Revit 2023, will help structural engineers working with typical steel buildings work faster and more precise, so that they could invest more in delivering more creative designs. Ever since we started working on this initiative, we had four main driving goals, each of them actually representing a benefit for the engineering community. Let me expand on each of them, while their listing order helps describe a basic workflow, right after you have installed Revit 2023.

Reduced iterations with fabricators for connections modelling

Structural engineers and fabricators can blend their own specific rules into libraries of connections, which will serve as the single source of information for all new projects.

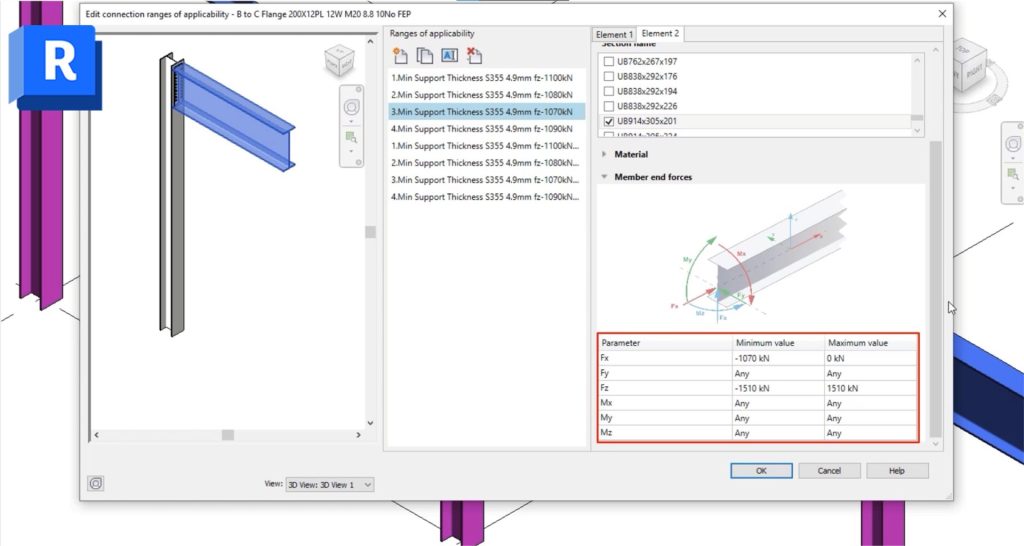

Along with Revit 2023, you will find sample libraries of steel connection types, configured according to some of the most used engineering standards. They have embedded associations between the connections proposed by the tables from the standards and the steel profiles to which they fit and the ranges of compatible member end forces. Single- or double-angles, shear end plates, seated connections, column splices, base plates, fin plates and many more typical connections like these are part of various Revit 2023 content packs, available via your Autodesk account portal or Autodesk Knowledge Network.

You can further expand or customize these libraries by creating new connection types, duplicating or editing the existing ones. It is during this step when you should reach out to the fabricators you work with and ask them to agree on the set of rules they would like to follow for the next projects, like using only connections with a particular bolt grade, avoiding any kind of chamfers, or having a preference for fin plates with 2 lines of bolts, rather than 1. Just to remove any confusion for my fellow engineers: these names that I’ve just used differ from country to country, even between USA and UK, some countries have certain connections standardized, other countries have different ones, and some have no official standardization. Still, the “Associate Connections with Profile Sizes” is meant to be a universal tool for all engineers to express the rules they need to respect for each steel connection type. And once all of these are saved in libraries, they can be reused across projects, saving countless hours and offering you the confidence that fabricators will have less RFIs addressed towards you. You could even think at turning the libraries of connections into contractual agreements.

Before wrapping up this section, let me tell you about the standards our sample libraries are based on: the AISC Steel Construction Manual 15th Edition and 14th Edition, the BCSA and SCI publication P358 – “Joints in Steel Construction – Simple Joints to Eurocode 3” – 2014 Edition (also known as the Green Book), and the German DSTV – “Standardized Joints in Steel Structures to DIN EN 1993-1-8” (“Typisierte Anschlüsse im Stahlhochbau nach DIN EN 1993-1-8”) – 2013 Edition. You can read more about what library is available for each pack here.

Faster design intent modelling

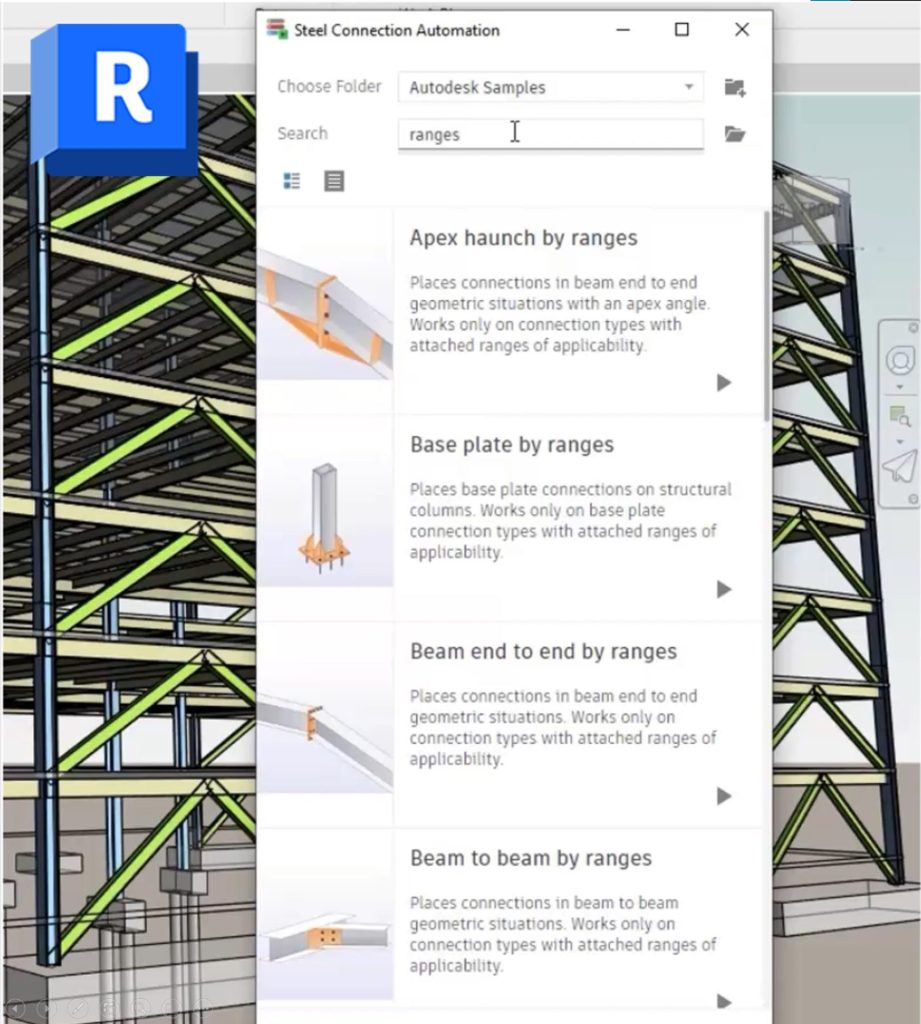

Imagine how easy it is to create the design intent model with steel connections, when you can take off the shelf the required ones and place them in the model, based on automation algorithms.

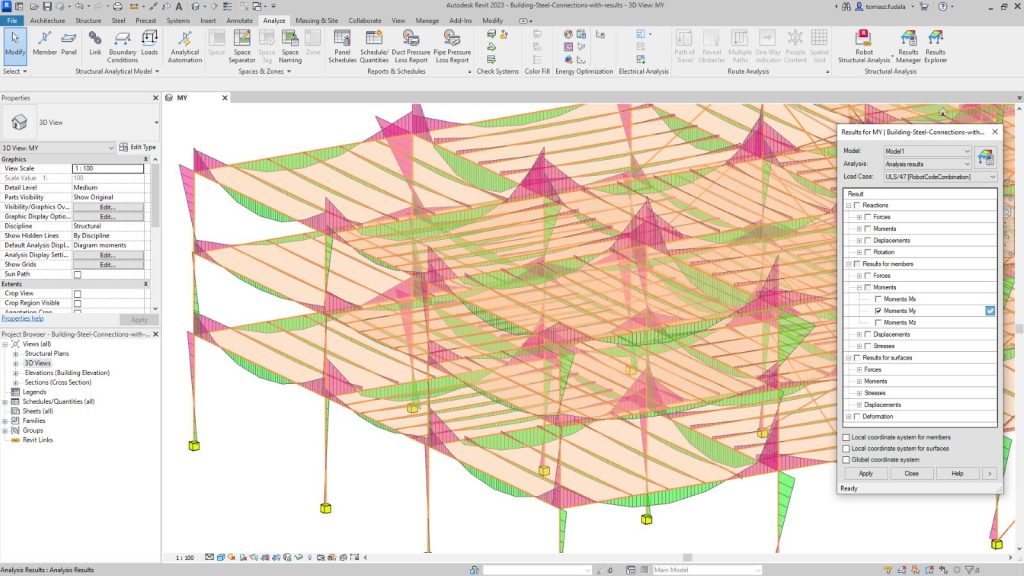

Having the libraries defined, the next steps of Connection Automation keep you on the track for a simple, connected workflow: start from your new Revit design intent model, transfer it to Autodesk Robot Structural Analysis Professional or other analysis software that can exchange analysis results with Revit to perform the structural analysis and bring it back to Revit, where our out-of-the-box rules read the results, look into your preferred libraries and match the intersections of steel elements with compatible configurations of connections, automatically modelling the steel connection types.

For an easy rules management, we created dedicated rules for each of the typical kinds of connections found in our sample libraries. I highly recommend you to read this page, for an in-depth overview of how you can efficiently use these rules.

This reduces the risk of accidentally placing end plates with 4 rows of bolts instead of 5, because our automation mechanism checks the actual shear force from the indicated load combination against the capable one defined for each connection type and will place the one capable of resisting that force. You could also reduce the risk of other troublesome scenarios, with potential large wastes of material, like using connections designed for beams made of S275 on a model made of S355 elements, because the ranges of applicability can compare the steel grades as well.

Just in case you may think performance would become an issue when dealing with so many connections, it’s worth saying that in Revit 2023 the overall performance of navigation in all views has been improved, our benchmark tests reporting an average improvement of 35% for more than 100 affected test cases. Moreover, the Analytical Model in Revit is now created on demand when needed, which means creating and editing detailed models with steel connections is up to 50% faster. You can read more about the other performance improvements for Structural Models in our “What’s New for Structures – Release 2023” blog post.

Estimate earlier: the constructability and cost for entire models with connections

Since connections can now be placed much faster, it means that more detailed design models, with connections, can be created quicker too. This empowers engineers to estimate faster and more accurately their proposal before submitting it for a tender, increasing their competitiveness. It gives you time to do more iterations on the design and takes away part of the tedious stage of modelling connections.

Constructability can be assessed earlier as well, because once connections are modelled, one can easily do a clash check using Autodesk BIM Collaborate. This way, the early design will be much closer to the final detailed model, by comparison to a traditional workflow.

New business opportunities to extend services to detailing

Having an accelerated process of the design intent model with connections, and having the ability to embed within the steel connection types and within the placement rules the various bespoke requirements of fabricators and of other project stakeholders, it might make sense to some engineers to increase the value of their services, by expanding into detailing. The Revit models would be richer in BIM data, in a phase almost similar to that which only detailers typically reach. Transfer the model to Advance Steel, add the remaining fabrication-specific logic and automatically create the shop drawings and NC files.

Revit 2023: Library-based connections design automation

I am not saying this is a trivial shift. Contractual agreements and industry practices don’t change overnight, but they are not set in stone either. They evolve, just like us, based on the knowledge we all amass day by day. This is what the visionaries from the industry have taught us, and this is why we put our effort in delivering these new tools. So that structural engineers can work more efficiently and deliver more value. As always, we are looking forward for your feedback, here, in the comments, on the forums, or in any other way you would like to share it with us.

More on Autodesk’s 2023 AEC releases:

Watch On-Demand

Public Roadmap Updates

Generative + Computational Design | Set a reminder: April 19, 2022

AEC Structures | Set a reminder: April 20, 2022

AEC MEP | Set a reminder: April 27, 2022

Architecture | Set a reminder: May 4, 2022

Read more and watch the highlight videos.