Digital twins have clear advantages and use cases for owners and operators of facilities, but they also present an important and exciting opportunity for AEC professionals to learn from and deliver their projects.

Starting a digital twin early in a project’s life cycle has many benefits for the project team, and Autodesk is excited to facilitate this through Tandem for AEC, available on the cloud-based design management and collaboration software BIM Collaborate Pro.

What is Tandem for AEC?

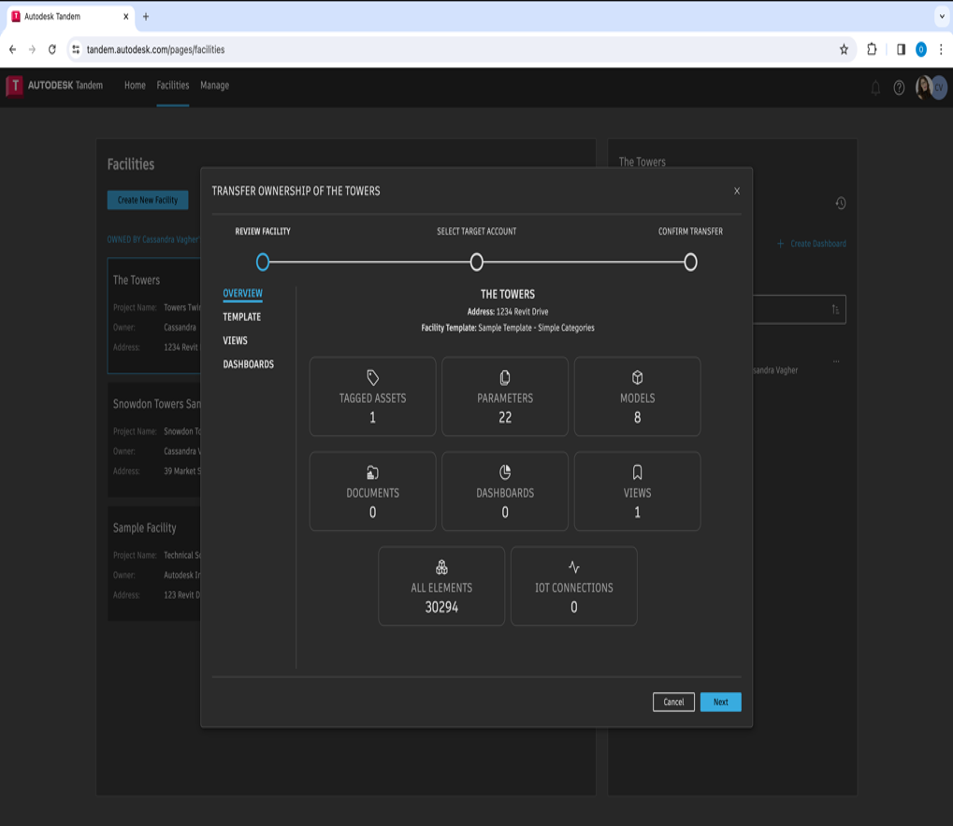

Tandem for AEC is Autodesk’s cloud-based digital twin solution that tracks and transforms a built asset’s life cycle, from design through construction and operation.

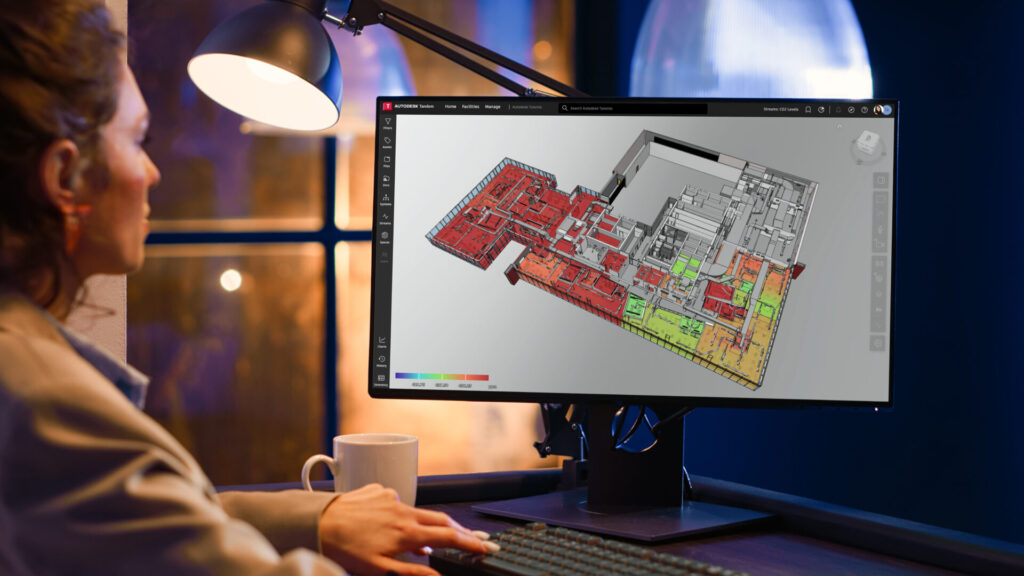

By integrating BIM data, Tandem helps AEC firms and building operators develop and deliver a digital twin where they can explore, monitor, and manage operational data – all on a user-friendly platform that combines 3D visualization of the facility along with all its operational data.

The importance of a digital twin

A digital twin is a replica of the built environment, typically a building, that has connections to real-world operational data.

Examples include data from IoT (Internet of Things) sensors that record indoor temperature or PDFs of equipment warranties and instruction manuals.

The data from the digital twin can then be tracked over time to help inform future design decisions or to, for example, observe how equipment and other assets are performing in near real-time. The digital twin continues to mirror the physical environment that it represents.

So, how can the AEC community use a digital twin?

Design and construction firms benefit throughout the project as teams utilize data from a digital twin to make informed project decisions. Digital twins enable project teams to improve client relationships by allowing project teams to offer additional services and increase efficiency of project handover.

Better understanding of performance and usage

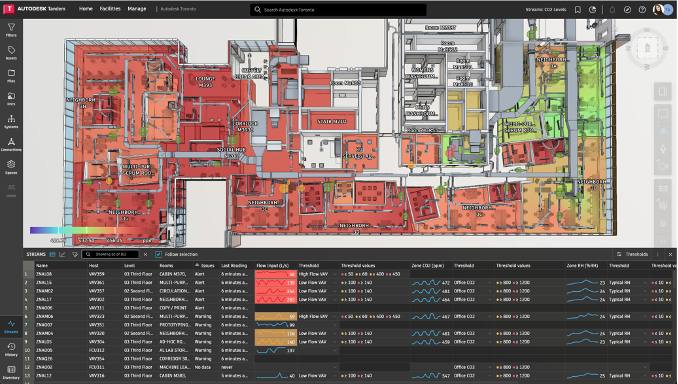

Design professionals who are trying to understand how a current space is used, for example, can utilize a digital twin to better plan for future renovations can rely on data from occupancy, CO2, and other sensors by visually analyzing the data in context to the building with heatmaps and historical data.

Find and flag problems

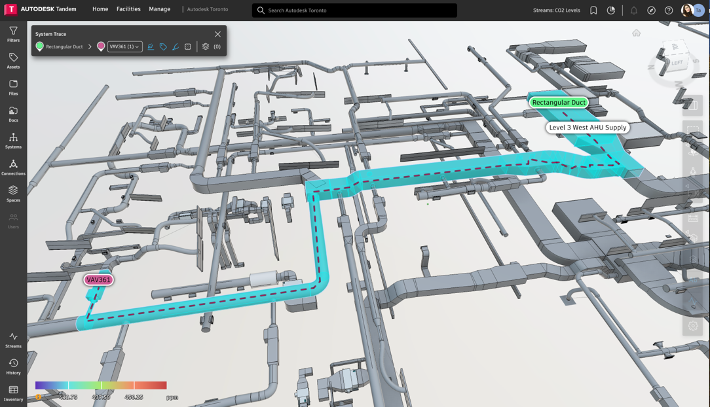

Engineers and contractors looking to pinpoint the location of a failed VAV box, for example, can utilize the digital twin to discover the problem, thanks to incoming data streams, and quickly understand the impacted spaces and systems via Tandem’s system tracing functionality.

Review efficiency

With Tandem for AEC, evaluating the efficiency of various building systems and creating commissioning reports is easier because the information is housed in a single source. With Tandem for AEC, evaluating the performance of various building systems is easier because data like pressure sensors and flow rates are reflected in a single pane of glass in near-real time.

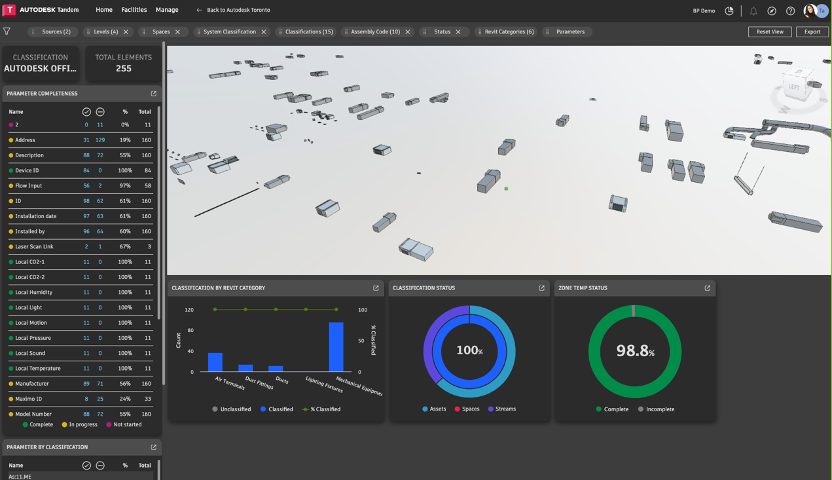

A Repeatable and Scalable Process

Easily track twin building process with Tandem’s dashboards. Tandem Dashboards make it easy to track which assets have completed information for handover facilitating a timely transition from construction closeout to building occupancy

What’s more, users can create templates so that the same information can be tracked across multiple properties — perfect for clients that own multiple properties like big box stores.

Easier digitized handover

Tandem for AEC also helps improve the relationship between AEC professionals and clients with a digitized handover for occupancy. All of the information about equipment serial numbers, installation dates, warranties, and more can be embedded in the digital twin – providing clients with digitized handover, making it easy to find, navigate, and maintain their asset data.

New source of revenue

Finally, Tandem for AEC provide a new source of revenue potential for AEC firms, since developing a digital twin is a new scope of work beyond the basic design and construction services. It’s one that can be done for in-progress designs as well as existing, completed buildings and projects.

Digital twin development

So, when should the decision to use a digital twin be made? Ideally, digital twin development happens early in a project, so that there’s an opportunity for close collaboration with the client or owner to confirm what data should be tracked and collected.

When it’s implemented early on, a digital twin created with Tandem for AEC helps project teams align and achieve desired operational outcomes. However, AEC firms can begin building a twin by leveraging BIM data at any point in the building lifecycle.

Packaging and interoperability

Tandem for AEC is available with BIM Collaborate Pro – so AEC firms can now expect even more value from their subscription. Direct interoperability with both Revit and IFC projects simplifies the process of updating models on both platforms for AEC professionals. Users can also employ an Excel plug-in to check, update, and add asset data.

Is Tandem for AEC right for your projects?

The saying “knowledge is power” exists for a reason: the more data a project team has, whether it’s the AEC professional or the owner, the better decisions can be made, regardless of project type, location, or size.

A variety of clients are already using Tandem for AEC — from complex, multi-year projects to small, simpler ones — and reaping the benefits of streamlined project delivery and asset maintenance with the help of digital twins.

Learn more about Tandem for AEC or contact Autodesk.