Macadamia nut trees were first planted in Kenya during the mid-twentieth century. While not a native species, coffee growers discovered the climate and soil were perfect for the trees to flourish. During the 1970s, commercialization took off. Now, macadamia nut trees are prevalent throughout the country and present a budding industry.

Despite the success of the first commercialization 50 years ago, the Kenyan macadamia nut industry still remains unstructured. Seeing the possibilities, Charity Ndegwa, Jane Maigua, and Loise Maina identified the challenges and opportunities available for small-scale farmers to bring the nut to market. As a result, the three women founded Exotic EPZ and began to build a network of farmers for a new processing and exporting business rooted in positive societal and environmental impact.

“Our goal was to start an organization that would bring healthy products from the African continent to the world. We want to have a positive and lasting impact in the community and the environment as well as promote social-economic growth in our country,” says Charity Ndegwa, co-founder and operations director, Exotic EPZ.

One of the largest barriers to success has been expanding access. Some farmers may have only a few trees, while others a small orchard. But all face the same difficulties of getting their product to market; transparency with the supply chain and pricing; and secure, prompt payment.

“We now have 7,000 small-holder farmers in 11 different growing regions and the buying process is very technology based,” Ndegwa says. “We’re keen on leveraging technology to help us streamline the entire process. We use a web-to-mobile based application called ‘Connected Farmer Application.’ This application allows us to register the farmers and record, among other things, their contact details and cite the number of trees, the acreage under cultivation, and their exact location.

“The system enables communication with farmers through the bulk messaging capability,” she continues. “This function is used to send out information on farmer field days, opening and closing of buying seasons, and any other agronomy information. The application also enables payment of farmers through the mobile money system (MPESA). It’s very exciting for them because they are paid promptly and accurately.”

Designing the Processing Facility With AutoCAD

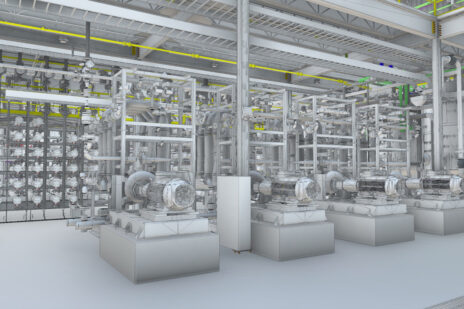

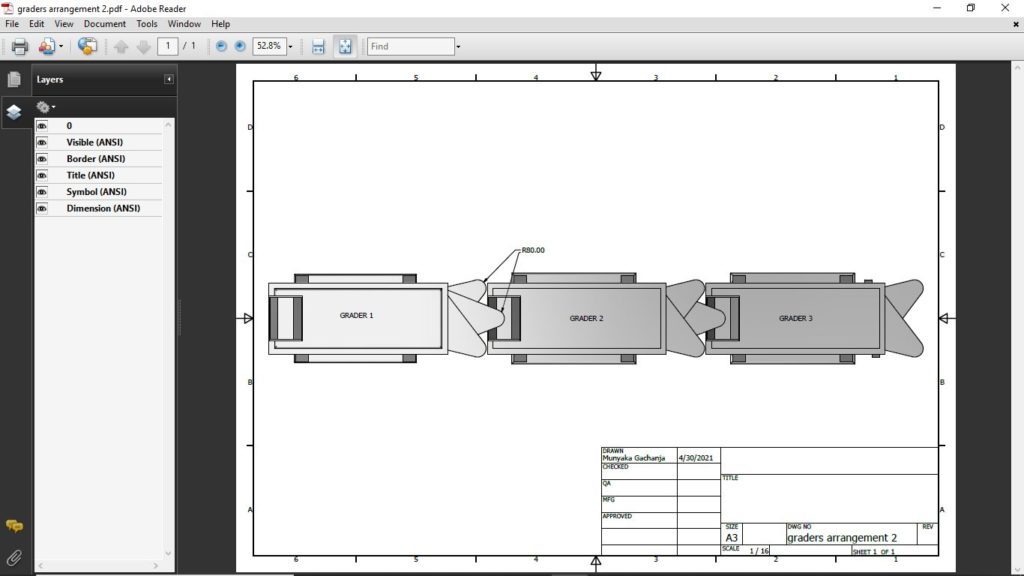

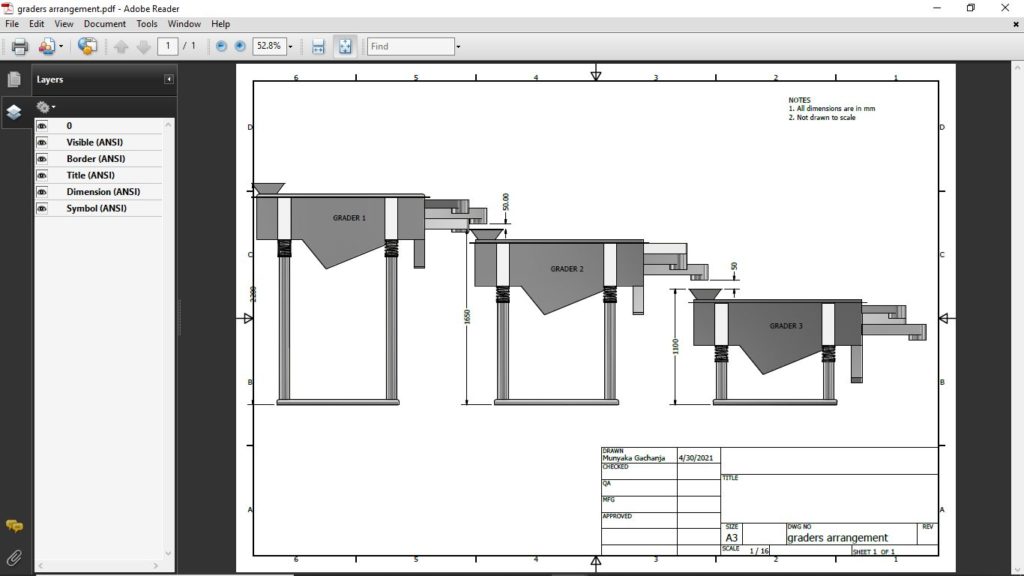

In compliance with the regulations in Kenya, macadamia nuts need to be processed locally before export. After operating for three years, Exotic EPZ needed to redesign the processing factory in order to create more space for new machine installation and expanded workforce as the demand for its macadamia nuts increased. After the redesign, the factory’s processing capacity increased from 5 tons to 10 tons per day and created jobs for 122 workers, 85% of whom are women and 75% youth.

With the help of Autodesk’s Technology Impact Program, the design team used donated AutoCAD licenses to design both the current facility update and the new and improved building that Exotic EPZ is planning to construct and equip by 2023. The new facility will further increase production capacity to 30 tons per day and create 60 new jobs. It is a testament to Exotic EPZ’s commitment to empowerment of small-holder farmers and create decent jobs, especially for women and youth in the community.

The ability to use 3D modeling and visualization, 3D navigation and section planes, a 3D DWG viewer, and PDF and DGN import/export underlay are crucial features for their work and the new facility design.

“AutoCAD is much faster and easier. There is a reusable block library in the software with features like copying and pasting into different drawings, which saves a lot of time. Precise dimensions simply aren’t possible with hand-drawn drawings. This accuracy is an important feature in our factory design, especially for the creation of new partitions and machine layouts.”

Lawrence Munyaka, Engineering Assistant, Exotic EPZ

One of the most important components of the facility is the food safety certification. Food safety standards require that the internal layout is designed, constructed, and maintained to facilitate good hygiene and manufacturing practices. All movement of materials, products, equipment, and people also require a very detailed design to protect against potential contamination sources.

“AutoCAD has enabled us to design a facility that meets international standards of food processing and hygiene, facilitating certification with one of the best food safety standards (FSSC 22000),” Ndegwa says.

The design team also enhanced the occupational health and safety aspects of the facility with AutoCAD, including the mapping of a factory evacuation plan in case of emergency situations and location of firefighting equipment and first aid kits.

“With AutoCAD, we can save time and money because it’s easy to design and view layouts, interpret and identify design problems, and store and transfer data safely.”

Jared Barongo, Head of Engineering Department, Exotic EPZ