The world of construction takeoffs has been evolving over the last decade. Rather than relying on manual measurements and static drawings, teams can now work with dynamic, detailed 3D models that streamline processes. Done right, 3D takeoffs are a game-changer in construction projects, improving everything from accuracy and efficiency to data gathering and collaboration.

Estimating teams are always under immense pressure to produce estimates faster while not sacrificing accuracy. You have to bid more jobs to win more jobs in a highly competitive landscape. With labor shortages across the board, any efficiency that can be gained through the digitization of outdated manual processes can result in big gains for a company. 3D takeoffs, when done with the right tools, can be that winning advantage that sets companies apart from the rest.

In this article, we'll explore how 3D takeoffs work, their benefits, and why they're becoming a must-have tool for construction professionals aiming to stay competitive.

Table of contents:

A 3D takeoff is a technology-driven process that uses 3D modeling software to extract accurate material quantities and measurements directly from digital project plans. For example, someone performing a 3D takeoff can calculate the exact volume of concrete needed for a foundation or the amount of steel required for a structural frame, all while visualizing these components in a detailed 3D model.

This approach not only enhances precision but also provides a comprehensive visual representation of the project.

3D takeoffs have several benefits that can transform your construction estimating process. Consider the following.

Unlike manual takeoffs, which rely on flat for 2D drawings, 3D models display the actual spatial relationships of project elements, so every detail is accounted for. This accuracy minimizes mistakes during procurement and construction, which means teams avoid over-ordering or under-ordering materials.

3D takeoffs automate calculations and measurements, so you spend less time manually estimating materials and costs. What once took hours or even days can now be completed in a fraction of the time. This efficiency streamlines the preconstruction phase and frees up your team to focus on other critical tasks.

3D takeoffs can help teams visualize the project in its entirety and quickly align on expectations. Interactive models allow contractors, designers, and stakeholders to understand the scope of work, putting everyone on the same page.

With 3D takeoffs, data is organized systematically, making it easy to access, update, and share information. Automated processes like quantity extraction and report generation reduce manual effort while keeping all information centralized. That way, your team always has reliable, up-to-date data to support decision-making throughout the construction project lifecycle.

By visualizing the project in 3D, you gain a more comprehensive understanding of how different components fit together. This paves the way for better planning for material procurement, labor allocation, and construction activity scheduling. When you have accurate data from the get-go, you're able to anticipate challenges and address them proactively.

3D takeoffs contribute to sustainability by reducing material waste and promoting resource efficiency. When your calculations are more precise, you can ensure that only the necessary materials are ordered and cut down on surplus that might otherwise end up in landfills.

For instance, Autodesk Takeoff even integrates with sustainability tools like the Embodied Carbon in Construction Calculator (EC3), which evaluates the environmental impact of building materials. EC3 analyzes data from Environmental Product Declarations (EPDs) to help construction professionals choose materials with lower embodied carbon. This empowers teams to make informed, sustainable decisions during the planning and procurement stages.

We've talked a great deal about the benefits of 3D takeoffs, but 2D takeoffs still play a significant role in today’s estimating workflows.

2D takeoffs are incredibly useful for straightforward projects or situations where simplicity and speed are key. 2D models, for example, come in handy when working with traditional drawings or when you need to focus on basic material quantities without getting bogged down by unnecessary information.

Meanwhile, 3D takeoffs excel in handling complex designs and providing deeper insights.

No matter what takeoff type your project calls for, a solution like Autodesk Takeoff streamlines the process by allowing you to conduct both 2D and 3D takeoffs within the same platform.

A 3D takeoff helps you get from model to estimate with ease. Here's what that process typically looks like.

You can't perform a 3D takeoff without the model, so the first step is to create an accurate and detailed 3D representation of the project.

With that in mind, the design team must ensure the model includes all necessary components, materials, and dimensions to support precise takeoff calculations. Collaboration between the design and estimating teams at this stage is crucial to avoid missing critical details.

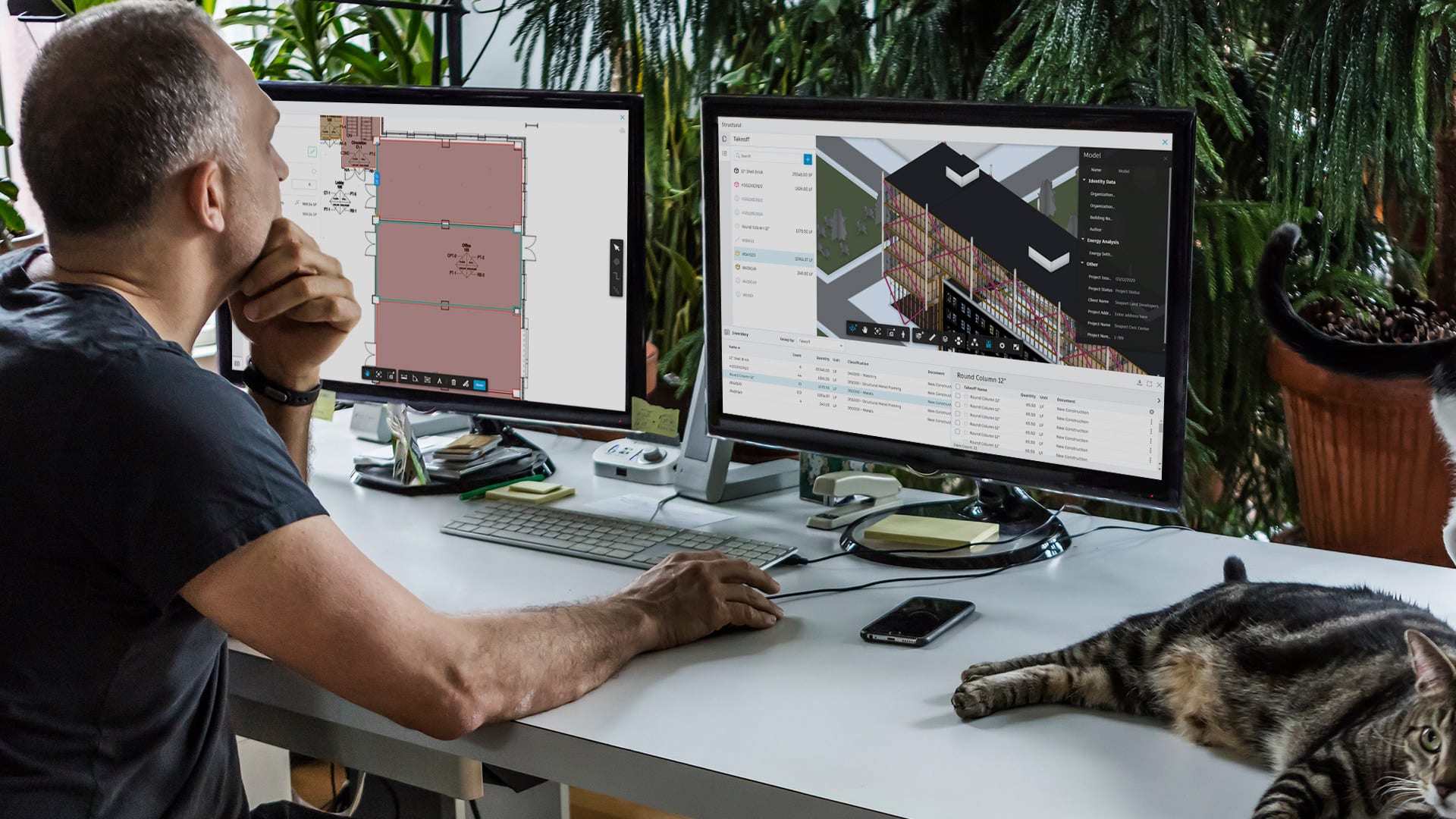

Upload your 3D model into your takeoff software. If you're using Autodesk Takeoff, for instance, you can upload 3D models in RVT or IFC format in the Sheets & Models tool.

Once uploaded, the tool processes the model, allowing you to view, navigate, and interact with it in a 3D space.

Next, set the parameters for your takeoff, including the specific materials, dimensions, and components you want to measure. In 3D takeoffs, these parameters can be as broad as total material quantities or as detailed as measurements for individual elements like beams or piping.

Using the tool's interface, select the elements within the model you want to analyze. For example, you can isolate walls, floors, or roofing components for material estimation. Highlighting these elements visually separates them, so you can review quantities and measurements without confusion. This step can also involve using filters to pinpoint specific materials or areas. Filters can be applied to exclude elements from the model to help you focus on specific design elements that you wish to account for in your quantities.

Once elements are selected, the software calculates and generates material quantities automatically. This includes calculating precise measurements for materials like concrete, steel, or insulation.

After generating the takeoff, review the results for accuracy. Many tools allow you to cross-check measurements against project specifications and adjust outputs as needed. You could also consider doing a 2D quantity takeoff for a couple of rooms and compare them with the 3D takeoff to see if the figures are consistent. If you find discrepancies, make sure you correct them before exporting and sharing the takeoff data.

The final step is exporting the takeoff data in a format that suits your workflow, such as Excel spreadsheets or PDF. Autodesk allows you to export one or more sheets with takeoff as PDF files so you can easily share them with stakeholders.

3D takeoffs have been around for a while now, but the space continues to evolve. If you're using 3D takeoffs, you can look forward to even more improvements, particularly in the following areas.

Put more takeoff-related tasks on autopilot. From generating material quantities to managing project data, estimating teams are increasingly benefiting from automated solutions.

Case in point: automated takeoffs in Autodesk. The platform lets you quickly extract quantities directly from models, saving time visualizing a project's scope. You can use customized formulas to automatically calculate complex quantities across 2D and 3D views and even save snapshots to preserve project data at specific phases.

Implement 2D and 3D takeoffs from one platform. With tools like Autodesk Takeoff, you can work with traditional 2D drawings and advanced 3D models within a single interface. This flexibility ensures that you can handle projects of varying complexity while maintaining consistency, accuracy, and collaboration across your team.

As more construction firms embrace sustainability, the demand for tools and practices that reduce environmental impact continues to grow. And it's worth noting that sustainable construction practices start even before the project breaks ground. As mentioned earlier, choosing low-carbon materials during the planning phase can significantly reduce embodied carbon and improve a project's overall environmental footprint.

The good news? With tools like EC3 integrated into 3D takeoff software, users can evaluate and select low-carbon materials directly within the platform, aligning projects with environmental goals.

3D takeoffs make construction estimating faster, smarter, and more accurate. Plus, with AI, automation, and sustainability being a bigger focus, adopting tools that keep you ahead of the curve is more important than ever.

With Autodesk Takeoff, you can streamline your workflow, reduce errors, and plan more sustainably—all from one platform. Ready to see it in action? Try Autodesk Takeoff today.