Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

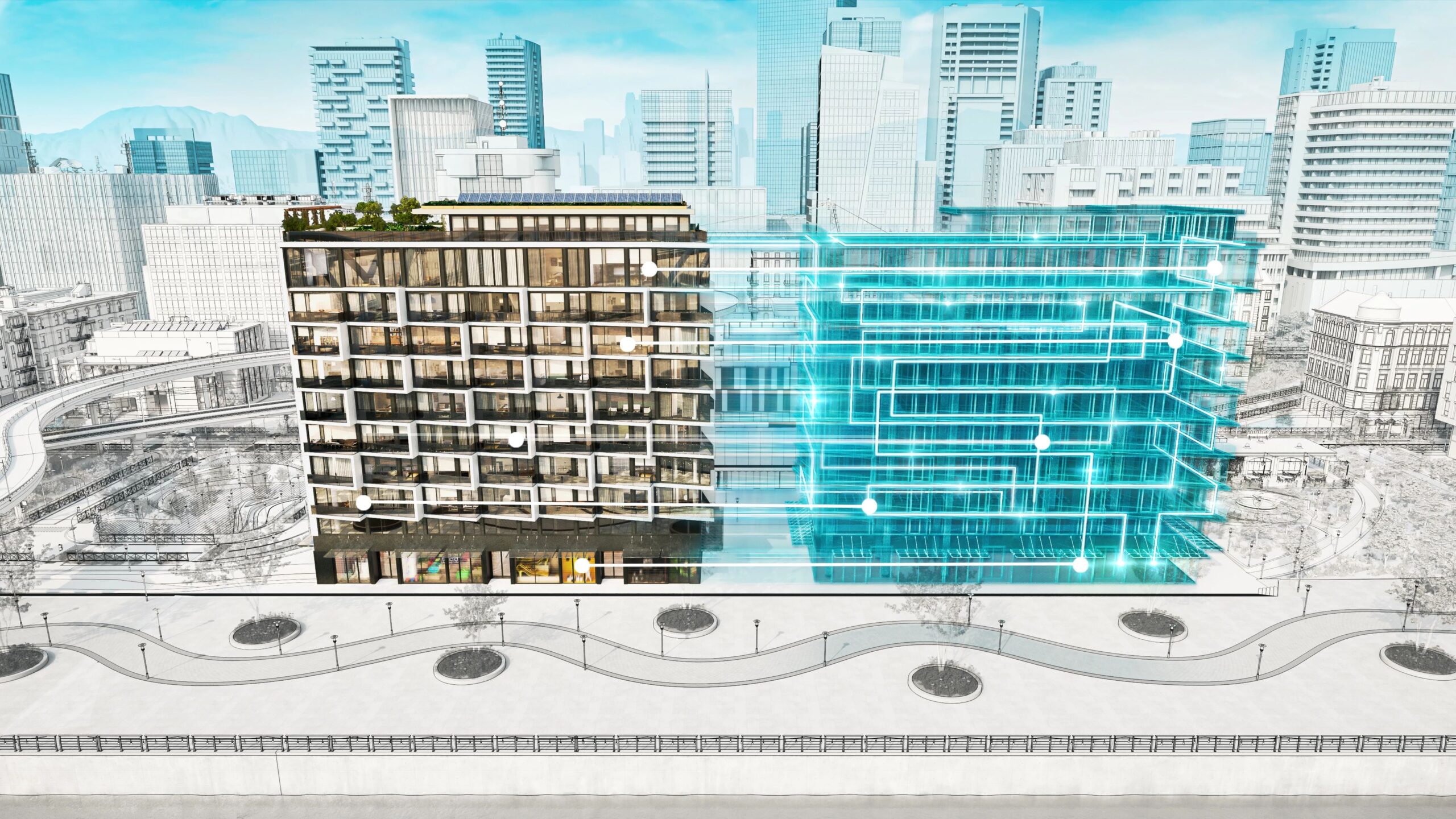

Real-time digital twins are set to reach a new point of maturity in 2023 with growing customer-proof points and technology advances improving scalability.

While static digital twins are already widely used across building industry, real-time digital twins represent the next stage in innovation. They link together building models, smart building data, and analytics to offer intricate replicas of real-world operations.

Read more: Bring Your Facility Manager to Your Next Design-Build Project

To date, real-time digital twins have largely been locked in the hype phase. There has been buzz, excitement, and proptech funding but limited deployments at scale. Many real-time digital twins have been built through services-heavy processes with bespoke data collection approaches, often resulting in expensive digital twins with limited repeatability.

But change is on the horizon as technology innovation meets customer demand.

Pilot projects have been helping the building industry to better understand the value proposition of real-time digital twins for facility operations. Autodesk’s own Project Dasher has shown the potential of digital twins to enhance the availability and quality of information across assets, energy, air quality, and space usage. This research project integrates building sensor data with model data to explore the value of contextualizing IoT data in 3D format.

Research firm Verdantix recently identified seven high-value applications of digital twins in facilities management. Their analysis of pilot implementations globally revealed that digital twins are helping facility managers improve fault detection and maintenance task prioritization processes, driving cost savings. Verdantix expect growing investment in digital twins; their survey of 350 facility managers found 31% will invest in the 2023.

From a facility manager’s perspective, digital twins have broken out of the ‘technology looking for problems to solve’ realm.

It is widely acknowledged that for digital twin adoption to grow, the industry needs easier and more cost-effective ways to create them.

Today, technology advances are starting to ease some of the challenges in building and maintaining real-time digital twins. Data integration platforms facilitate faster connections between digital twins and IT/OT systems. Richer built-in software functionality enables customers to deploy digital twin platforms with less customization.

To drive industry transformation, Autodesk Tandem is focused on building highly scalable digital twins and is working with numerous customers on digital twin implementations. One of the core enablers is Tandem’s framework of repeatable workflows that will make it easier for owners and AEC firms to embrace digital twins. Its workflow starts with helping owners specify their data requirements and operational outcomes from the start of a project. It also offers templates to capture asset, space, and system data during design and construction.

Read more: Mind the Gap: Connecting AEC And Operations Data

Tandem has also partnered with cloud integration vendor Reekoh to leverage its rapid, scalable, and repeatable integration tools for operational technology and business data. This will enable Tandem to use low-touch data acquisition and integration processes to connect with a customer’s physical and digital environments in a scalable way. This will enable owners and operators to use their digital twin to understand the performance of their assets and spaces with granular operational data. Drawing on this partnership, Tandem is in public beta for a new set of facility monitoring capabilities that enable users to review real-time data from systems and connected assets.

What will fuel digital twins to truly scale up?

We expect the AEC services firms will be a major driving force for the digital twin landscape. And for good reason. The foundational data for digital twins are generated during design and construction processes. Digital twins with the capability ready to link into real-time operational data, should be the natural output of the project lifecycle. AEC firms looking to get on the front foot of this opportunity to grow their business and differentiate against competitors should act today.

Read more: 3 Things We Learned About Getting Started With Digital Twins

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.