Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

Anyone who’s ever tackled a colossal to-do list knows that a scattershot approach doesn’t work very well. That’s why you clean house systematically from room to room. It’s why you plan errands in advance, to take the most efficient route and avoid traffic. And it’s why we prioritize tasks that build on one another, to minimize waiting and wasting resources.

It’s all about workflow–and if you’re not thinking about maximizing construction workflows, you’re missing out on key efficiencies. So much so that you might find yourself falling behind competitors and missing major opportunities.

So, what separates a good construction workflow from a poor one? Why does it matter? And ultimately, how do you fix shortfalls? Let’s take a look at all of this, and more, below.

Interested in learning how to better benchmark your construction workflow? Download our guide, "The Ultimate Guide to Benchmarking Construction Workflows."

Before we get into how to optimize workflows in construction, let’s take a step back and look at what actually defines a workflow to begin with: Workflow involves the specification, implementation, and automation of organizational operations. In a workflow, team members transfer tasks, information, or documents to one another for further action, guided by a predefined set of procedural guidelines. Workflows help organizations facilitate task coordination and data synchronization across systems, ultimately enhancing organizational efficiency, collaboration, and profitability.

It’s obvious how this applies to construction, where tracking tasks and managing documents is a considerable part of the overall process, from preconstruction through construction project closeout. Because it streamlines and clarifies each stage of the process, implementing strong procedures for each part of the construction process has significant benefits for any firm.

Need a reason why you should be focusing on construction workflow improvements? Here are a few critical reasons:

While construction workflows can bring huge boons to your company, that’s only if they’re well thought out, understood by every member of the team, and relevant to all processes, methods and materials. Unfortunately, many construction workflows are not well organized and implemented, and that’s a problem.

Typically, they break down in one of three areas:

Luckily, failure isn’t set in stone. Now, let’s take a look at how construction professionals can start to improve workflows, step-by-step.

Before we get into the six construction workflows construction professionals are more likely to waste time on, let’s take a look at traits that equate to universal success. Four of the most critical construction workflow traits include:

Want to whip your most critical construction workflows into shape? Here are six construction workflows to improve stat.

Time is wasted in preconstruction workflows when various stakeholders feel disconnected from one another. Since there are so many teams involved in this stage, the problem is rampant in many projects. Whether it’s bidding, estimation, or qualifying subcontractors, there are a few too many cooks in the kitchen. As a result, documents and data can be disorganized, missing critical files, or get buried in the inbox. Teams struggle to get their ducks in a row when it comes to organizing and collating all the necessary information to start a project off on the right foot.

Here’s how to improve the preconstruction workflow:

Building information modeling (BIM) is generally touted as a time-saving construction strategy–but only if it’s used correctly. Improperly implemented, BIM can lead to even more wasted time, especially if there is the use of duplicate information, incorrect information, or gaps in modeling. This can frequently happen when two different teams model the same set of elements.

Additionally, data is often lost when models are used in the field. Originally detail-rich property data, for instance, is flattened into PDFs when sent into the field, leading to lost information. The attempt to recover or make sense of incomplete data can lead to errors, rework, and wasted resources.

Here’s how to improve the BIM workflow:

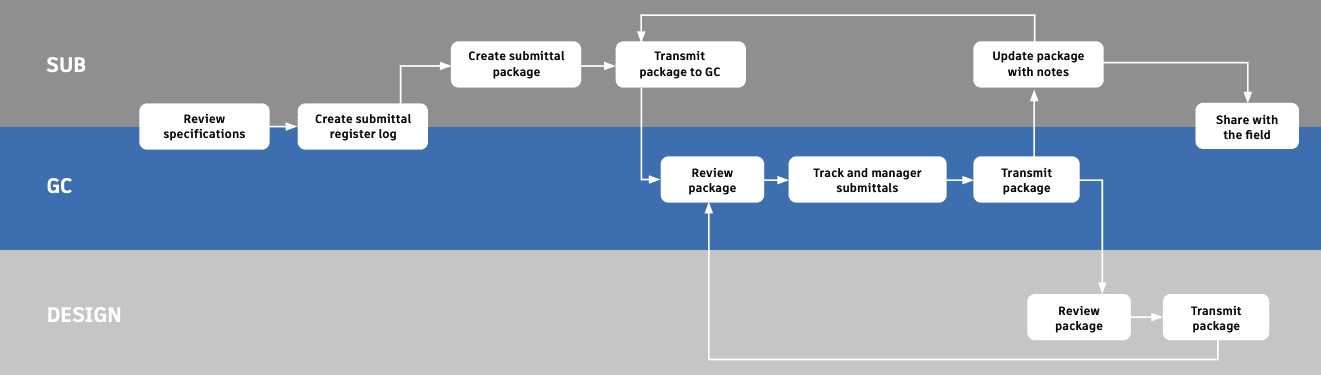

Submittals is one of the most important construction project management workflows to start off a project on the right foot, and one of the most commonly botched.

Typically, the submittals review process is long and brutal. Stakeholders need to aggregate them from all engaged contractors, ensure they cover each aspect of the project and input them into a system–often manually, which introduces mistakes and omissions. This can take weeks or even months, and as the project grows in size and scope, so do the errors.

Here’s how to improve the submittals workflow:

Without a comprehensive submittal log, it would be impossible to manage the submittal process confidently. If you are looking for a submittal log template, download our free template here.

While at times painful, requests for information (RFIs) are a necessary part of any project, and without solid project management workflows RFI processes can suffer. RFIs ensure that crews build correctly, reducing rework and maintaining quality. But for all that they’re essential, RFIs can be roadblocks to a project if the process is not streamlined.

According to a report from Autodesk and Dodge Data & Analytics, 68% of contractors see increasing the adoption of processes to frequently and consistently capture RFI data as a massive barrier. Unanswered RFIs can lead to cost increases and time overruns on all types of construction, so it’s important to manage them with intelligent workflows.

Here’s how to improve the RFI workflow:

Instead of throwing your hard hat down in frustration, using a template for the RFI process provides consistency and improves the process on the whole. Looking for a template for construction RFIs? Download our free template here:

Punch lists are essential to closing out a project, but they can be left to the last minute and can delay closeout further. Manually keeping track of punch lists can also waste time, as there is no transparent and accurate system to see the status of a task.

When it comes to punchlisting continually throughout the construction project (also defined in the Autodesk and Dodge report as punch list-as-you-go), only 44% of general contractors are utilizing this method on at least half of their projects. In many projects, closeout is delayed because punch list items are not properly managed and handled ahead of time.

Here’s how to improve the punch list workflow:

Want to set up for closeout success? Download our Ultimate Project Closeout Checklist:

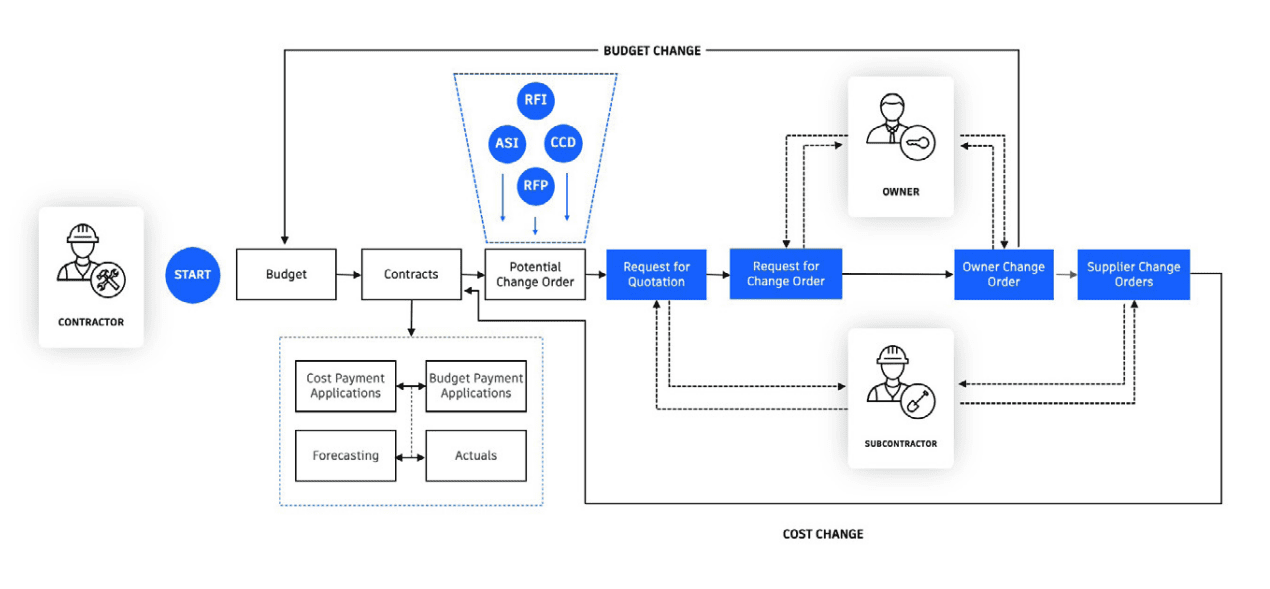

Tracking costs, managing risk, and keeping a project on budget can be one of the biggest hurdles in a construction project. For instance, a typical construction project can have dozens of change orders. Therefore, finding efficiencies in cost management workflows can make all the difference in delivering a project on time and on budget.

Project executives and project managers often have to navigate information silos, which increases risk due to outdated or missing information, unreliable response times, and convoluted processes involving a variety of vendors, systems, and products. Most importantly, teams need accurate, real-time data on the financial health of the overall project so that well-informed decisions can be made quickly.

Managing construction costs throughout the lifecycle of a project, including tracking change orders, managing supplier contracts, and visibility into overall budget impacts, is tedious. Project managers and engineers often have to navigate information silos, which increases risk due to outdated or missing information, unreliable response times, and convoluted processes involving various vendors, systems, and products. Most importantly, teams need accurate, real-time data on the financial health of the overall project so that well-informed decisions can be made quickly.

Finding efficiencies in cost management workflows can make all the difference in delivering a project on time and budget.

Read more: Technology's Critical Role in Cost Management

Here’s how to improve the cost management workflow:

Change doesn’t happen overnight. You can’t expect your team or your firm to finetune every single one of their workflows right off the bat. Approach workflow changes like a marathon – it will take time to implement them, work out the kinks, and onboard everyone, from the highest stakeholder to the newest worker.

Even if you start today, you can expect to go through a transition period of several months. For that reason, there’s no time to waste. Get started with optimizing the fundamental construction workflows above today.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.