Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

In construction, last impressions matter. Owners and clients expect a seamless handover, which is the key to efficient facility management and operations. For contractors, a clean handover process is also a way to win more work and retain loyal clients. But while construction project closeout is essential, planning for a seamless handover happens well before ground is broken. In fact, the process begins as early as the design phase and is carried on throughout construction. The main driving force behind a successful project is improved commissioning.

Table of contents:

Project commissioning, also referred to as Cx, is a series of milestones that includes the testing of systems, materials, and staff who will be operating the systems. The term originally comes from the shipbuilding industry—once commissioned, a ship is considered ready to operate.

In construction, commissioning is the process of evaluating a building to be ready for service. As a quality assurance test, it starts in design and continues through operations. Much like shipbuilding, the process involves a series of documenting, scheduling, and testing processes. The goal of commissioning is to ensure that the facility operates according to the Owner’s Project Requirements (OPR), which form the basis of all decisions related to construction and operations.

Project commissioning can be broadly broken up into two types of building groups: new and existing. Let's explore the several types of commissioning based on these building types:

This type of commissioning is to ensure a new buildings components, equipment, and installations operate as specified.

The goal of BECx is on performance of the building envelope. These components include energy efficiency (e.g., doors, roof, windows, wall installation), as well as end-user comfort (e.g. air quality).

This type of commissioning extends beyond the baseline commissioning needs. ECx includes everything from extended warranties of systems and equipment, lifecycle costs, and extraneous documentation and plans needed to ensure systems can be operated and maintained on a regular basis.

FCx involves ensuring that the building's core assets and systems including HVAC are operating according to owner requirements and project design intent.

Existing building commissioning occurs after the facility has been occupied to evaluate and identify any improvements for occupants and building owner.

CCx is a systematic and on-going approach to evaluate areas to improve energy and other efficiencies, as well as address any operational issues that impact comfort or pose a risk to occupants and extend the building lifecycle.

RCx is typically a cost effective and periodic commissioning method that analyzes and enhances existing building operations and controls to improve energy efficiency and improve systems holistically.

Retro-commissioning is particular useful for older buildings that did not have extensive or any commissioning practices during original construction.

Every facility is unique and in reality, no two building's commissioning phases will look exactly alike. However, there are common phases when it comes to construction project commissioning.

In this initial phase of commissioning, the overall building and owner requirements and goals are outlined. This includes determining needed stakeholders and the commissioning team, as well as creating a documented plan. Sometimes, a commissioning provider (CxP) will be hired in this phase who is a company or individual that manages the entire process through operations as well as provides reports and recommendations to the project owner. Other companies may have an internal commissioning manager to also fulfill these duties. The commissioning schedule is also typically determined at the construction planning phase to ensure targets can be met.

Once the commissioning team has been selected in the pre-design and planning phase, they will have the opportunity to review all design docs during this phase. This enables the team to create a list of performance and operational requirements for all building systems and equipment. Oftentimes, a commission checklist will be created to keep the entire team on track and ensure design intent.

During construction, commissioning activities are on-going once equipment and systems are installed an are operating as intended. The construction and commissioning teams will work in tandem to ensure issues are identified and resolved to keep on schedule.

Once construction is complete, the acceptance phase begins. Final testing occurs during this phase of commissioning. Notably, construction handover processes begin with extensive walkthroughs with and training and documentation for the building owner and building operation team. A final commissioning report is typically produced at the end of the post-construction phase to document everything is up and running according to requirements.

At this time, on-going commissioning efforts are handed off to the building owner and operation team. This involves maintenance on all required systems, equipment, and controls to extend a facility's lifecycle and efficiency for as long as required.

According to Whole Building Design Guide, “Buildings that are properly commissioned typically have fewer change orders, tend to be more energy-efficient, and have lower operation and maintenance cost.”

Let's explore the additional benefits of a well run commissioning process throughout the project lifecycle.

Commissioning is especially important for energy management. Today’s owners are looking to build more sustainable and energy-efficient buildings in order to cut costs, and OPRs might include sustainable goals like those outlined by Leadership in Energy and Environmental Design (LEED) standards. These standards were created by the United States Green Building Council (USGBC) over 15 years ago to promote practices focused on sustainability, and commissioning is an important part of the LEED certification process.

In general, the LEED building commissioning process is a highly effective method to improve the performance of building systems and equipment. It ensures the presence of energy related systems such as HVAC, plumbing, electrical, fire safety, building security, and renewable energy systems. A strong understanding of these standards throughout the different phases of the process can lead to greater satisfaction for owners and clients.

LEED lays out several phases of project commissioning. In the first phase, a commissioning lead is selected, and development of project requirements begins. This is when the initial OPR is reviewed or created and the commissioning plan is laid out, and this plan is updated as the design phase continues. In the next phase, submittals and shop drawings are reviewed for related systems, and observation and testing are carried out throughout construction. In the last phase, outstanding issues are reviewed and resolved and a final report is submitted. With commissioning, quality assurance occurs at all of these phases.

If the commissioning agent (CxA) has knowledge of LEED, they can help project teams meet the requirements to become LEED certified. They do this by ensuring design plans meet both OPRs and LEED certification requirements, making sure equipment and systems are working at the correct efficiency level, organizing regular site visits throughout construction to confirm ongoing efficiency, and modifying control programs to improve operational efficiency and occupant comfort while decreasing energy use. Improved commissioning can earn as much as six points towards a LEED label.

In this first phase, the commissioning agent is generally hired by the owner to ensure an unbiased assessment. Early participation of the commissioning agent in the design phase ensures that potential issues found during occupancy can be addressed before becoming major problems, thus reducing construction risk. In fact, the USGBC now requires that the commissioning agent be engaged by the end of this phase for this reason.

In design review, the commissioning agent can identify problems that may arise during handover and bring that knowledge back to design. Important aspects of this well coordinated process include centralizing communications and construction documentation. It is crucial to explicitly document design requirements needed to meet performance expectations. This also serves as a comparison to what actually gets installed during construction. Better access to models and documents for schematic design, design development, and construction document review, as well as proper LEED documentation, can help ensure that the design meets the owner’s requirements.

Throughout construction, a well-coordinated commissioning process entails constant communication and collaboration to ensure project requirements are met. A useful solution to improve commissioning in the construction phase is utilizing a construction management and asset platform. This type of solution offers software that allows for the tracking and management of assets within a construction project from start to finish. It can easily include the commissioning agent and provide access to the field. Project teams gain easy visibility into the status of the project, keeping everyone updated and reducing the time needed to move into operations. This allows for accelerated commissioning and reduced risk throughout the process.

A collaborative workflow submittals process is vital in the commissioning process. Prior to breaking ground, the general contractor will provide the commissioning agent with a set of equipment and system submittals. These include equipment and product data sheets, shop drawings, details on installation and start-up procedures, operations and maintenance data, performance data, and temperature control drawings. The agent should be kept in the loop regarding these submittals throughout the process. This way, they will understand any new design intent or operating changes, and change orders that may impact commissioned systems, ultimately ensuring compliance with OPRs and a satisfied owner.

For successful commissioning during construction, it is also important to bring in the facilities management team to review maintenance needs. Shop drawings, models, and virtual reality technology can be used with the facilities management team to review clearances and accesses to important post-construction needs.

As part of quality assurance, issues identified during design should be revised by the design team and tracked during construction to ensure these problems are taken care of. Any checklists created by the commissioning agent can be easily set up in field software like Autodesk Build and tracked collaboratively throughout construction. These checklists can be pulled up during inspections to ensure that equipment has been delivered to the jobsite, a system or component is started up per the manufacturer, operational, and more.

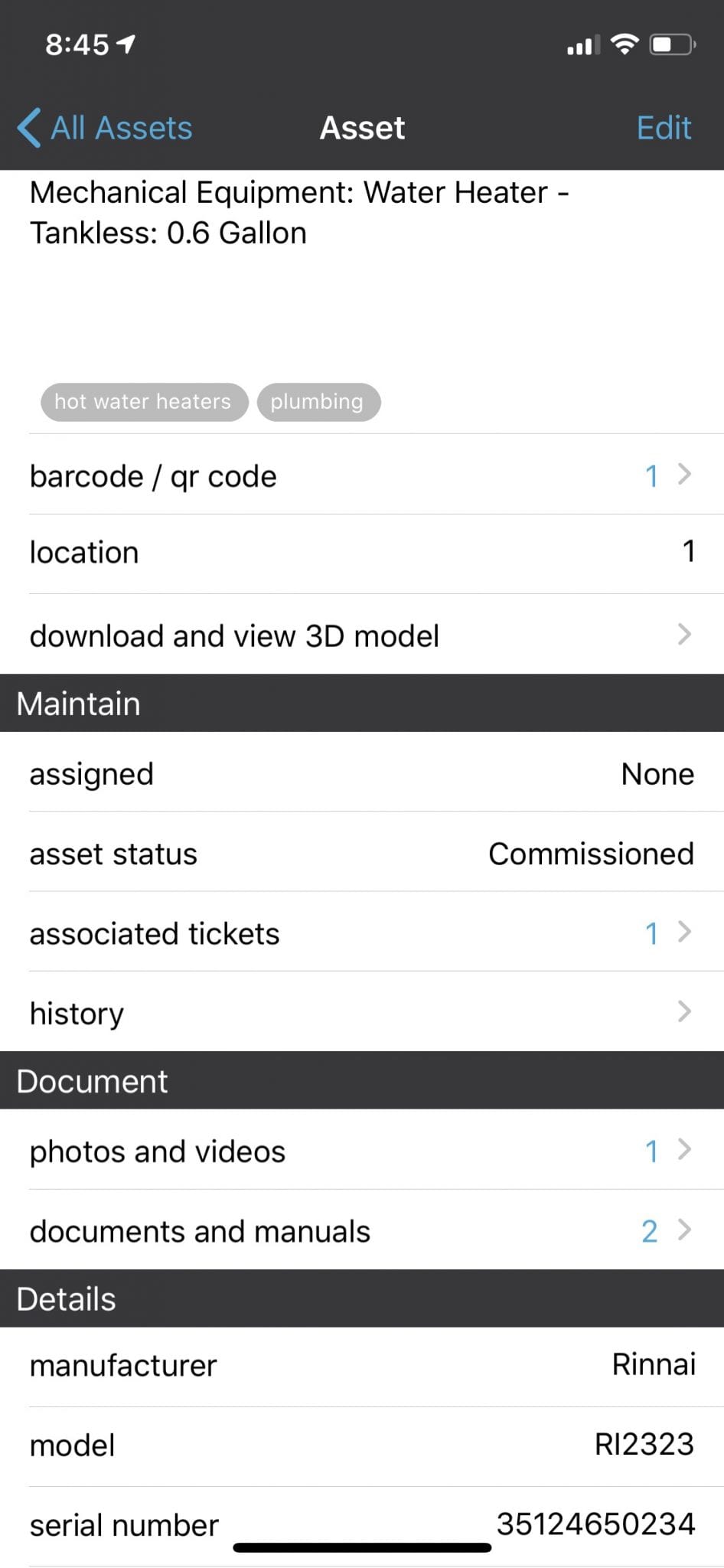

Finally, asset tracking is critical to an efficient commissioning process. The Assets module in Autodesk Build helps speed up the commissioning and handover process. Asset and equipment serial numbers, warranty dates, and other necessary information must be collected for the owner while installing and starting equipment. This can be done directly on the jobsite on a tablet or mobile phone using the cloud-based technology.

During this last phase, all remaining commissioning issues must be closed. Whether you’re on a mobile device or desktop computer, ensure all commissioning issues created proactively via checklist have been resolved before handover. Using Autodesk Build, teams can alert crews to any possible issues as well as inspections that take place during the commissioning phase of construction. And when construction is over, the appendix and documentation for the commissioning report is only a click away.

To ensure that the building is operations ready from day one, handover documentation needs to be effortless. All the data collected during construction must be readily available for operations teams. Facility teams need to access detailed asset information including both PDFs and 3D models, create and update tickets, training videos and allow for predictive and preventive maintenance, all from the convenience of a mobile device.

Owners today are looking for greater sustainability in order to reduce lifecycle building costs and increase building performance. To meet these requirements and have a seamless handover, there must be strong project commissioning from the design phase, throughout construction, and all the way to closeout. Following LEED guidelines while commissioning can provide improved sustainability, thereby giving owners the cost reductions they are seeking. Improved commissioning centers around adherence to these LEED guidelines, as well as using technology to ensure the process is proactive and everyone is kept informed at all times.

With effective commisioning comes a smooth handover, less change orders, and repeat clients. When done well, project commissioning leads to greater satisfaction and a successful project overall.

Learn how to optimize your Construction Handover workflow with this ebook:

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.