Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

Help us improve your experience. See content that is made for you!

See how IBM increased their efficiency by up to 30%!

A recently published report from Autodesk titled Digital Sustainability: The Path to Net Zero for Design & Manufacturing and Architecture, Engineering, & Construction (AEC) Industries shows that the Nordic construction sector is in a healthy position with regards to sustainability and digital technology adoption, in relation to other European regions.

The comprehensive study from Autodesk, in partnership with Market Research Consultancy Frost & Sullivan, is based on a survey of 600 organisations across the AEC and Manufacturing segments in three key European regions: UK & Ireland, Benelux and the Nordics. The survey garnered responses from 126 Nordic AEC companies, 53 of those were in construction.

In this piece we’ll take a brief look at the current environment for Nordic construction, the key stats from the report, and how technology can help accelerate sustainability. Firstly, let’s take a look at some of the positive highlights of the report:

Before getting into the stats from the industry, it’s worth looking at the Nordic market in general, for context.

The research shows the Nordics as the most mature for sustainability. There is a long legacy of companies in the region driving sustainability through strategic leadership rather than through government, focusing on the environmental, social, and governance (ESG) aspects of corporate strategy and building capabilities and expertise in sustainability when servicing their projects and clients.

There is also a cultural drive towards sustainability, innate in the region, evidenced by the fact that customers and investors are driving the urgency and momentum of sustainability.

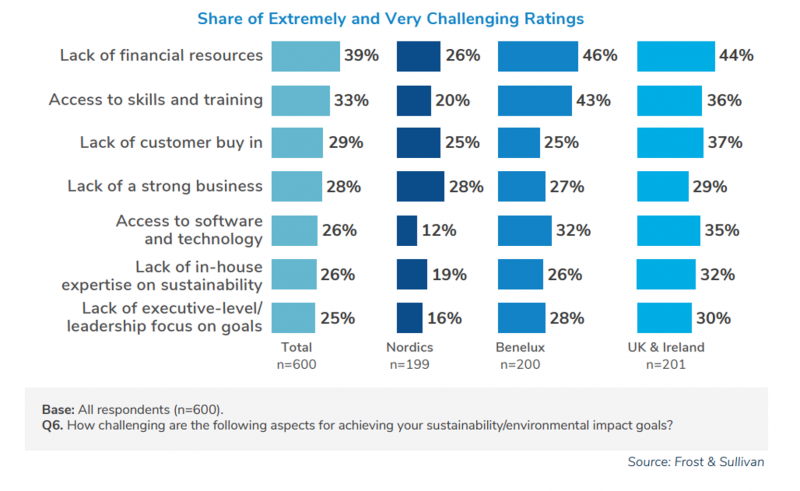

The maturity of digital sustainability in the Nordics is highlighted by the region’s view of access to software and technology as a challenge at only (12%) compared to the other regions - 32% (Benelux) and 35% (UK/IE). Overall Nordic respondents rated all perceived barriers to achieving sustainability as much less challenging than the other markets.

Given the maturity level on the Nordic markets, it was perhaps surprising that when asked, how important sustainability/environmental impact is to company strategy, only 6% of Nordic construction companies said that sustainability was a cornerstone of their strategy. The majority (51%) said that sustainability was ‘one of their areas of focus’.

70% of AEC companies and 65% of all Nordic companies surveyed cited better use of resources as the strongest benefit of sustainability to the Industry.

It’s also worth noting that Nordic companies are least likely to engage in sustainability initiatives for awards and recognition (22%) compared to almost half of Benelux and UK/IE respondents. The second highest score amongst the perceived benefits of sustainability was reducing energy consumption.

When looking at the impact of different stakeholder groups and departments as the drivers of sustainability, the view of all regions was the sustainability strategies are driven by customers and clients, followed quite closely by strategic leaders. Interestingly in the Nordics employees are seen as fundamental in driving impact strategy (68%).

Competitive advantage was seen as the key driver of embracing sustainability at a corporate level (83%) in the Nordics. Ranked second at 73% was regulation and market forces, which is further testament to the sustainable maturity of the region.

One other key score when comparing regions was that employee attraction as a key factor (59%) was much higher than both Benelux and UK/IE at 30% and 39% respectively.

When we look at it by region, the score is slightly reduced (42%) with 49% in the Nordics stating that Circular design is the most important driver of customer projects.

The demand for easier collaboration between supply chain and partners is particularly high in construction (52%), due to the large number of suppliers and vendors involved. This is in contrast to Architecture and Engineering’s (A&E) 43%, which has far fewer suppliers. However, support via new data insights and capabilities are stronger in A&E given the need to influence the downstream construction segment in terms of material specifications and performance linked to sustainability.

Material alternatives and zero waste (Lean Construction) is a key trend set to accelerate in the sector also. The high rating of zero waste (Lean Construction) is a strong indication of the promising prospects of key technologies, such as robotics, 3D printing, and pre-fab and modular construction.

There is a growing importance of a common data environment (CDE) also, which will give teams access to real-time data for design coordination and review.

Not confined to the Nordics, but very much worth noting were the responses around what will have the biggest impact on carbon emissions in construction. The biggest opportunity is Prefabrication (53%) with Circular construction and Lean following at 43%.

Embodied carbon in materials, in both manufacturing and construction, is a priority as companies look to reduce carbon intensity with use of alternative materials on the journey toward net zero.

“Circularity is emerging as a new way of thinking. Success requires a shift in a mindset of the construction industry enabled by technology. The main objective is to help our customers achieve their sustainability goals by driving circularity”. - Janicke Poulsen Garmann, EVP for Norway at Norconsult

The report shows that the businesses across the Nordics are forward thinking, driven both internally and externally on sustainability. However, there are still opportunities to accelerate change, embrace new ways of thinking to drive further and faster towards a more sustainable industry. Key to that acceleration is the utilisation of digital technology is a key enabler.

Net zero building construction is critical in tackling climate change. The evolution of BIM extending to the digital twin solutions enables sustainable construction by incorporating economic efficiency, energy and resource efficiency, and environmental performance in different stages of construction. The key role of the solutions is monitoring, measuring, and managing the processes and operations, in terms of architectural and energy performance.

“When we do large scale construction projects, we place a big emphasis on BIM to ensure we minimise the impact in the process. We also do this to digitise what is in the building, such that years later, it becomes a resource bank so that we might not need to go to Congo for cobalt or to China for earth metals”. - Mattias Goldmann, Head of Sustainability at Sweco

Cement production and calcination account for 8% of global anthropogenic CO2 emissions, which is about four times that of the aviation industry. Due to the massive consumption of carbon-intensive materials and the associated high emissions, robotics and 3D printing can significantly reduce the construction sector's environmental impact, and project costs.

“Our focus is on how the technologies we develop can have a potentially enormous positive impact in reducing construction's environmental footprint. To achieve this, we are making robots accessible. Factory on the Fly is a robot module in a container and can go to the construction site and the factory. Basically, that means that you can avoid a lot of emissions that are related to logistics because you can bring the factory to the construction site”. - Asbjørn Søndergaard, Co-founder and CTO at ODICO

In Sweden, research and development projects involving various stakeholders in the construction sector are aimed at tracking information from the source to the building, and then developing standards, frameworks, and protocols. This can have a significant impact and help drive sustainability and circular economy agendas with respect to construction projects.

Companies are also looking to drive good health and well-being in construction, with a focus on air quality and lighting. The role of digital solutions is increasing, ranging from sensors to drones. A shift in design and manufacturing from mitigation to adaptation is needed as the world deals with systemic change from increased natural disasters and the Covid-19 pandemic.

Mistakes can increase the carbon footprint of construction projects. Rework creates waste, emissions, and pollution. Reducing errors, minimising waste and increasing quality – the principles of lean construction – can not only support sustainability but improve the performance on projects.

Digital collaboration platforms like [Autodesk Build] help to reduce mistakes by ensuring everyone has up to date information at their fingertips: enabling the team to build right first time.

And finally, prefabrication is seen as having the greatest potential to reduce the industry’s carbon emissions (53%). Fabricating components off-site is not only more energy-efficient, but reduces the waste created during construction – and so the environmental impact of the build.

Nils Rage at Landsec explained that using a design for manufacture methodology on a project in London optimised the amount of materials needed, “so for that same building, we’ve shown a reduction of about 20% in embodied carbon compared to the same building being built traditionally.”

If you’re interested in learning more about the Autodesk Construction Cloud, visit https://construction.autodesk.eu/

Or download the full report - Digital Sustainability: The Path to Net Zero for Design & Manufacturing and Architecture, Engineering, & Construction (AEC) Industries

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.