Advanced Work Packaging (AWP) is a Construction Industry Institute (CII) best practice that brings a construction-focused approach to planning and collaboration systems for building capital projects. The process of AWP brings construction professionals into planning from the start to facilitate the early development of detailed work packages that will ultimately guide field activities.

While the AWP process has been well documented, traditional AWP technology applications have been difficult to deploy and not scalable in their application to all projects. While there are many solutions that support massive projects, most projects are small to medium in size and require a different approach.

How can firms find the right solution to leverage AWP applications in a scalable, effective manner?

Generally, uniform solutions fail to fit individual needs. Instead, firms must take a fundamentally different, individualized approach to AWP workflows. In this article, we’ll explore the roots of AWP, its benefits and challenges as well as new solutions designed to enable small-to-mid-sized project success.

Advanced Work Packaging (AWP) is a process framework for industrial construction projects that facilitates engineering planning to be driven by construction sequencing.

Traditionally, the design and construction departments work in silos. The engineering team breaks up work and documents produced by design and construction so they can make sense of needs from an engineering perspective. However, that doesn’t mean those needs translate to logical construction packages. Construction tries to make sense of this information, dividing it up and adding workarounds for anything that doesn’t correspond with actual conditions or constructability.

AWP turns the process in the other direction. This construction-driven approach to project design and execution begins with the end in mind. The order of planning is rearranged to improve efficiency and effectiveness, and construction is involved in planning from the start. Engineering deliverables are aligned with the Path of Construction, so construction priorities also become top priorities for engineering and procurement. From the beginning, work is broken down into smaller pieces of work, or “packages,” that align with the Path of Construction.

AWP addresses many of the obstacles that occur in traditional construction planning such as information siloing and preparation failure. Despite AWP’s simple and logical nature, implementing and perfecting the approach comes with several challenges.

Traditional AWP applications are often not cost-effective enough to deploy small or mid-capital projects. Most construction software is built to benefit large-cap projects yet the majority of projects are small to mid-sized. The good news is there are solutions out there.

Even when these applications are deployed, they often take months. You need solutions that work well right when you need them to. It shouldn't require a time-intensive and costly waiting period to deploy AWP.

Many traditional applications require dedicated server infrastructure and support to manage their operation. This administration and overhead can add substantially to the implementation efforts.

Once complete, AWP projects may still result in paper-based, high latency workflows. This only adds to the frustration of users as they try to get comfortable with a new technology yet still encounter many of the same challenges.

Much of the data stored and used by legacy systems is specific to that system, and difficult to use outside of that system. This enforces a siloed approach and leads to recreation of effort in other systems.

In addition to proprietary standards, many legacy platforms do not have the ability to support integration into all of the other systems that will be required.

Projects may have many design software solutions, but merging all of this data together is a challenge for legacy applications that expect to see all of the data in the formats specific to that platform.

Autodesk has been on a journey to provide a fundamentally different approach to AWP. This approach is centered around an open, extensible platform for core functionality and partners that solve last-mile solutions for specific workflows. It addresses one of the largest challenges in AWP: scaling the solution to projects of all size and scale.

Unlike traditional AWP applications, Autodesk’s solution is completely scalable, making it cost-effective for any project. You can start tapping into the advantages of AWP the same way with a deployment period that lasts just minutes, instead of months. Instead of relying on paper-dependent workflows, AWP’s approach features real-time, paperless workflows. The cloud-based solution is available on the web and mobile as well as offline.

Unlike traditional AWP applications, Autodesk’s solution is completely scalable, making it cost-effective for any project. You can start tapping into the advantages of AWP the same way with a deployment period that lasts just minutes, instead of months. Instead of relying on paper-dependent workflows, AWP’s approach features real-time, paperless workflows. The cloud-based solution is available on the web and mobile as well as offline.

Autodesk Forge and Autodesk Construction Cloud Connect leverage public APIs to help to support many of the workflows within the AWP process. This allows a rich ecosystem of partners and customers to develop and integrate into Autodesk Construction Cloud.

To get started with AWP, focus on these four key areas:

Divide work based on the Path of Construction by packaging plans. The number of packages may vary but the overall goal is the same. You want to make the complex simple by creating manageable and executable packages of information, materials, and work.

AWP relies on specific roles for project team members. These roles include:

AWP elevates time on tools by packaging constraint-free work so that construction teams on the jobsite have the tools, materials, and information they need to perform their work with confidence and without delay. By involving construction early in the AWP process, you can improve efficiency and reduce waste. Be sure to engage engineers and project managers in a collaborative exchange with construction.

To achieve the maximum ROI from AWP, it’s critical to follow the correct order of activities. Let’s walk through what to expect and how to get the most out of AWP.

AWP begins when all stakeholders and project team members agree to collaborate from the very beginning to create the best execution strategy. This needs to include everyone from the owner to engineering, to procurement, and construction.

This team should plan to work together to define the order in which planning will be done. Subsequently, the team will determine what information is needed and when. That way, engineering can put information into the design model that is useful to the team in construction.

Start by defining the POC, which should represent the optimal sequence of activities in delivering the physical scope of the project. Once the POC has been defined, break the project into geographical areas called Construction Work Areas (CWAs) that are determined by the POC.

Identify boundaries for each of the CWP’s as the next layer of granularity in construction sequencing. The engineering team will use these boundaries to create Engineering Work Packages (EWPs) based on these CWPs. As engineering progresses and the EWPs become more complete, the construction team will use this information to continue the process of developing the CWPs.

During this phase, the CWP will be further broken down into Installation Work Packages (IWPs). An IWP contains all the information for a construction work crew to complete a portion of an installation. An IWP is designed with safety, efficiency, and predictability in mind and is typically structured so a crew can complete a single IWP in about a week. IWPs are created by the workface planner, then approved by the responsible stakeholders.

Our extensive, well-supported network of partners offers the solutions needed to scale AWP in one platform: Autodesk Construction Cloud.

O3 Solutions: This modern SaaS platform leverages Advanced Work Packaging and agile methods to help construction firms improve productivity, safety, quality, and predictability.

Datum 360: The connected data platform is designed for managing Engineering Information and Asset Management data requirements.

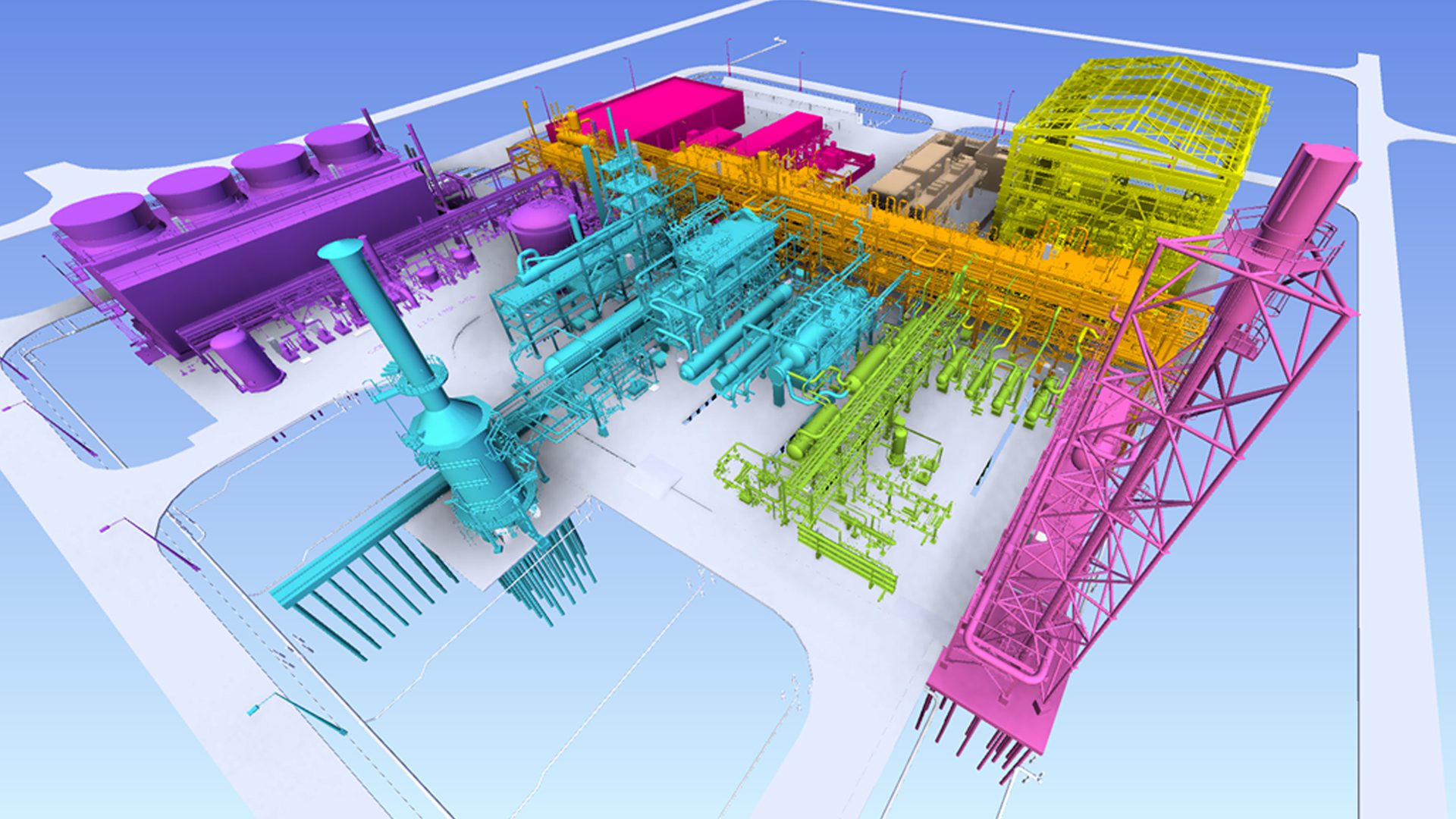

iConstruct: The BIM software for Autodesk® Navisworks® improves project performance, and drives collaboration and efficiency across the project lifecycle by ensuring a high-quality conditioned model.

BlackSmithSoft: The cloud-based platform combines all project-essential elements in one place such as 3D models, schedules, constraints, costs, budgets, documents, field progress, and dashboard reporting.

Intelliwave: This platform supports the identification and tracking of construction materials, equipment, and tools on all sizes of industrial, infrastructure, and buildings projects.

Traditional advanced work packaging applications are monolithic in nature, making them difficult to implement. They’re often bloated with unnecessary solutions. This is where Autodesk comes in, providing an accessible, scalable way to leverage the benefits of AWP. To learn more about AWP, join Autodesk at an upcoming AWP Conference.

For more information about making AWP scalable for your projects, visit our AWP page.