As leaders in developing regenerative infrastructure to design a better planet, Acciona is dedicated to the development and management of infrastructure and renewable energy. Their services cover the whole value chain – from design and construction to operations and maintenance.

Acciona’s business activities are based on its strong desire to contribute to economic and social development in the communities in which it operates. And making a positive impact to society is something that its largest project on record is doing in São Paulo, Brazil.

Acciona is the lead company responsible for resuming the construction of São Paulo’s new metro line. In 2021, it signed a deal to take over the construction, maintenance and operations of the São Paulo Metro Line 6 – also known as the Orange Line. The project is valued at €3.3 billion and once complete, will serve 633,000 passengers per day.

The sheer size and scale of the project is the biggest undertaking to date for Acciona. It is also the largest public-private infrastructure project under development in Latin America, and during the construction period, it will generate up to 9,000 jobs.

Fifteen underground metro stations are currently under construction, running along a total of fifteen kilometres of railway, with 22 trains in operation. In aggregate, it consists of:

Over the project lifecycle, more than three million cubic metres of earth and more than one million cubic metres of rock will be excavated.

The metro line will connect the centre of the capital to the city’s northwest corner, crossing through several neighbourhoods where some of São Paulo’s main universities are located.

For Acciona’s team, the project was challenging on account of several factors:

But one extra challenge faced by Acciona’s team was that it was resuming the project after several years of it being on hold, meaning that a pre-construction phase was almost non-existent and that construction should be resumed almost immediately.

Where do you begin when it comes to resuming a mega project of this size after it has sat idle for so many years? The answer is simple: Building Information Modelling (BIM) coupled with a fast-track design development.

On resuming the project, Acciona began a journey to implement BIM across the various disciplines supporting the design process. Pedro Rey Anton, Acciona’s BIM Manager, comments: “We needed to move away from manual methods to resume work quickly and efficiently. We needed to stablish platforms, rules, systems, and a multitude of a connections generating since the project inception a collaborative environment. Additionally with the help of reality capture, we began supporting the construction process right from the onset.”

Multidisciplinary teams are essential for the successful delivery of complex infrastructure projects. And the São Paulo metro line project involved several different specialties from Acciona’s internal project team and supply chain partners including structural, architectural, plumbing, fire safety and ventilation teams. But with so many different specialities involved, it can be difficult to ensure everyone is on the same page.

To ensure that all information flowed smoothly between different disciplines and stakeholders on the São Paulo metro line project, Acciona partnered with Autodesk to deploy Autodesk Docs, an Autodesk Construction Cloud product, to establish a Common Data Environment (CDE) for all project parties.

This meant Acciona’s internal and external project team members had access to important project data wherever and whenever they needed it. Now, whether it’s information on the as- built-to-date to plan for works, or information on design revisions, all project team members know where to go to find the information they need.

Reflecting on previous ways of working, Pedro says: “A project of this size and scale would not work if we used manual processes – they are often slow and prone to errors. We also used to rely on paper-based workflows on other projects which can lead to a lack of coordination and communication between team members.”

For the Acciona BIM team, using a digital environment to review the project design, identify interfaces between different elements of construction, and develop constructability solutions meant significant time savings.

“Our team accesses Autodesk Docs from their laptops or smartphones on site or in the office,” shares Pedro. “We’ve established Autodesk Docs as one of our key tools when it comes to decision making in both the design and construction phases of our project.”

But a project of this magnitude and complexity requires more than one use of BIM. Variations between project sites and disciplines required the team to analyse and develop different uses of BIM for the different workflows that make up the project.

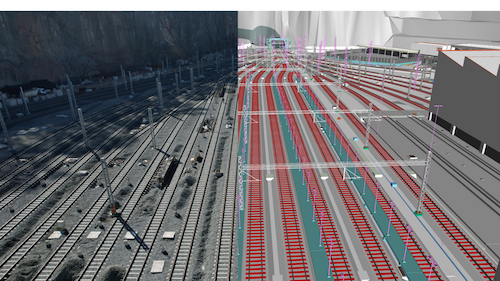

Coordinating models to conduct clash detection in the design phase has helped, for example, the team working on the Morro Grande train yard to identify issues before getting onto the construction site. For Acciona, using technology like this supports project teams to access the information they need whenever they need it.

“The filter feature in Autodesk Docs made it incredibly straightforward for project team members to navigate to the information they need. And we also used the permissions feature to make sure the team could only access data for the stations they were working on,” reflects Pedro.

“With Autodesk Docs it’s very easy, simple, and quick to navigate through a pretty complex and heavy model,” says Pedro. Previously project members would have had to have used high-powered computers to access federated models from the office. Now everyone can access the right information within seconds – regardless of the size and complexity of the model.

Paola Garcia, a construction area manager with responsibility across four stations, describes the ease of accessing Autodesk Docs on site. “We in the field use the Autodesk Viewer to view the model from any device, whether that’s a computer, phone or tablet. We can view the work-in-progress models as we find ourselves walking through the actual work.”

Acciona BIM team can set permissions so users in the field can’t modify the designs, though they can contribute to the model by verifying information and commenting on possible improvements – all in real time.

Using BIM methodologies means the São Paulo metro line team at Acciona and its partners can visualise all elements to the project.

“Being able to see the project in a 3D model has allowed us to catch potential errors and problems much earlier in the process,” says Pedro. “In the past, the site teams had been constructing assets without a visualization tool to show them what the result would look like.”

This resulted in wasted time, construction needed to be reworked, and created frustration for the teams working on site. “Being able to visualise the end outcome before construction begins has added clarity.”

Paola underscores how BIM methods are saving time and money. “Once all the information is collected in the BIM model and arrives in the field, we can do a preliminary study of the upcoming elements to build and generate a step-by-step of how we will prevent rework and reduce the risk of executing an element that causes us to go over budget.”

For Acciona, establishing Autodesk Docs as the project’s CDE means all stakeholders can access digital models of the assets – even if they have limited knowledge or use of BIM.

With more than 1,000 models for this project alone, team members with little BIM expertise can gain access to project data in a simple way, allowing them to better understand the project and contribute more effectively.

For site managers like Paola, this access has helped to simplify the complex for all the teams supporting her work. “We’re entering into a stage within the project where we need the information to be summarised not only for us, but also the subcontractors and the technical staff that support the work, given its volume.

“Autodesk Docs allows us to visualize how the different units will be finished and how much we have left to do. This helps us involve all the support teams in fulfilling what is, in the end, our ultimate goal: to finish all the different construction units in time, with quality, and taking into account all the requirements the customer requests.”

By being able to easily view and navigate the 3D models of the station at Santa Marina, for example, team members can see the station in reality and in Autodesk Docs.

“This has helped our supply chain understand how the various elements fit together easily. It reduces confusion and ensures everyone is on the same page – something that is crucial when we must deliver the whole project in such little time,” says Pedro.

Acciona’s newfound data standardisation has really changed the game when it comes to enhanced partnerships. “For us, standardising how we manage and share information has upgraded our collaboration techniques, reduced errors, and enriched the quality of the information we capture,” says Pedro.

For the community of São Paulo, the successful construction of the metro project is proof new ways of working can be delivered. And for ACCIONA, implementing BIM on large-scale infrastructure projects has led to improved efficiencies and better outcomes in record time compared to traditional method.