By embracing innovation while maintaining the highest quality, Belgian general contractor Vanhout has grown into a diverse construction group since its start in the 1920s. Its unique in-house engineering department has continually evolving know-how in building information modelling (BIM).

Vanhout takes on a wide range of construction work, covering healthcare, office, residential and industrial projects, and beyond – an indoor velodrome is among its recent accomplishments. The company is part of BESIX, Belgium’s largest construction group with more than 15,000 employees worldwide.

As Vanhout’s BIM manager, Yasmine Van Roosbroeck truly appreciates the company’s focus on innovation, particularly as she applies it to digitalisation and sustainability. For Yasmine, going digital is about improving processes, being more efficient, and achieving better results for Vanhout, its partners and clients.

With 10 years’ experience as a project manager on construction sites, Yasmine can take a well-informed approach to change. She knows what works on site, and what doesn’t.

When Yasmine started working at Vanhout, the team used different cloud platforms for design, documentation and execution. Yasmine’s vision was to streamline this work through a single platform, keeping everyone on the same page throughout each project lifecycle.

Yasmine moved Vanhout’s work onto Autodesk Construction Cloud. “Now all our projects start on Autodesk Construction Cloud. For me, this has the big advantage of bringing together a lot of different modules, a lot of different functionalities which are otherwise divided over three, four or five different platforms, which made it a lot more difficult to handle.”

Vanhout introduced Autodesk Construction Cloud to the team through three test projects using Autodesk Docs and Autodesk Build.

“First, two residential projects were selected, because we knew we would get feedback rather quickly on them,” Yasmine explains. “We invested time in making a good model for these projects from the outset, ensuring everything was executable so that we could build the buildings. We knew the projects through and through, and that's why these were also good study cases for how we could use Autodesk construction tools.”

With the two pilot projects going well, Vanhout chose a different kind of challenge for the next phase. “The third project had a larger scope: a combination of a renovation and a new building. It's a very beautiful building with a lot of personality in the city of Antwerp that we're innovating and making into a new school.”

Yasmine describes her team’s progress from its first use of Autodesk Construction Cloud, which focused on getting comfortable with Autodesk Docs, onto learning about Autodesk Build, and eventually going further into the platform’s capabilities.

“We had started by using Autodesk Docs to get to know the basics. To be sure, it’s as stable as we expected and hoped it would be. So we were getting more and more familiar with Autodesk Docs as our centralised document system, and began learning what Autodesk Build could do.

“And then we started to evolve slowly, using more and more functionalities from Autodesk Build on our projects – Forms, for example. We are always working hard on construction quality controls, internal and external. Our main focus is to get our work to the high level we want it to be, not just for our clients, but also for ourselves. We are ISO 9001-certified, and we have been able to add our quality plan to Autodesk Build through Forms.” Over 6000 quality inspection forms were created by the teams, testifying to Vanhout’s commitment to quality. In addition, to maintain order and eliminate waste, Vanhout has been practising the 5S lean principle through ACC’s quality functionalities.

Vanhout found that Autodesk Build offered her further options for streamlining processes. “As we started using Build, I found I preferred using the submittals workflow because of the flexibility it offers. Not only for my team, but also for the external parties we work with, it's really been advantageous.” For the projects, using Autodesk Build has meant the submittal process from start to approval is averaging around 26 working days.

With the three pilot projects now going to handover phase, Yasmine’s focus has turned to issues, which she can search, markup and compare through the Sheets tool. “Sheets is something we're starting to use more and more – Sheets combined with issues.”

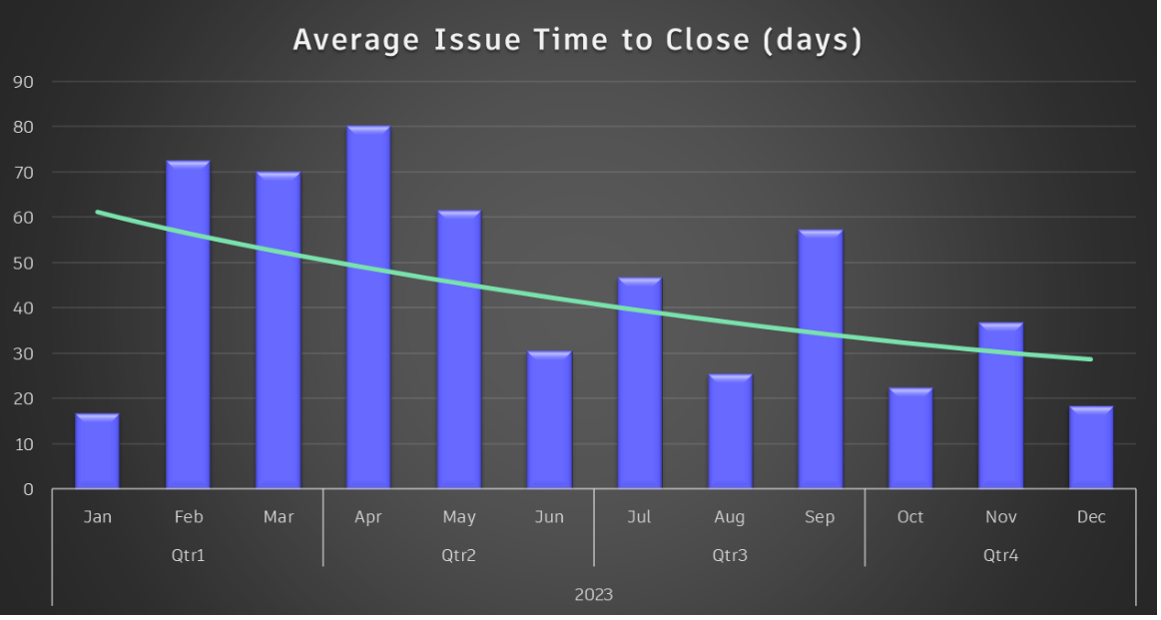

Having all issues, from design to handover, on a single platform “is definitely an advantage,” Yasmine reports. “Subcontractors have to review only one centralised list of items.” Vanhout’s average closing time for issues has reduced by a dramatic 75%, to 18 calendar days, an impressive accomplishment considering the construction FIDIC benchmark of 28 days[1]. In fact, less than 15% of the total issues on the project are older than one month.

After using the pilot phase to learn their way around the platform, Yasmine and her colleagues now aim to use Autodesk Docs and Build for all of Vanhout’s projects. And they continue exploring how the technology can help them do more.

“We wanted to have a solid base before taking the next steps,” Yasmine explains. “And I think by using the forms, sheets and issues functionality, we've got the important things covered and we are ready to move forward. And now it's my intention to look into the Assets and Scheduling tools, for example, in more detail. Those are two big next steps.” These features will allow the team to create a comprehensive visual record of the construction site, simplifying management even further and create accountability through weekly updates.

To enable cloud-based design collaboration on the projects Vanhout is involved in from the design phase, and also getting to know Autodesk BIM Collaborate and Autodesk Takeoff. At the bidding phase, Vanhout has already been trialling the Takeoff tool to improve tendering efficiency. “It’s looking promising,” says Yasmine, “so when the next project comes along, we’ll be driving it further.”

The Vanhout team has found third-party integrations with Autodesk Construction Cloud to further support their efforts at innovation. “We worked with an OpenSpace 360-degree camera on a couple of our pilot projects. It’s an interesting tool and being able to link it to our projects in Autodesk Construction Cloud makes it especially easy to use.” Integrations of this kind help the Vanhout team to capture all issues in their Autodesk Construction Cloud environment.

Rather than a broad rollout across Vanhout, Yasmine’s strategy is to give people the information they need when it’s most relevant to them.

“Not everybody is starting with the technology at the same time. So we are giving everybody who's using it, or going to use it, their own instructions, adjusted a little bit to the nature of the project at hand,” she explains. “We do this when necessary, and not three months in advance, because then they'd forget it. And then for submittals, which usually start a little bit later on the project, I give a follow-up course.”

Yasmine is happy to share materials and know-how with partners. “If we want to use these tools, we have to make sure that our partners understand them too. Most of the companies we work with want to use it as well, especially architects and designers. I give them courses of about an hour or two, to get to know the Autodesk Construction Cloud environment. This gives them the opportunity to ask questions. It’s quite a time investment from my side, but it’s worthwhile, because if we don’t do this, we won’t be able to use the tools to the standards we’ve set.”

Since adopting Autodesk for construction across the business, Vanhout has seen how BIM can save time and expense by reducing rework. “Modelling is eliminating a lot of flaws in design. For example, we had a project where the height of the stairs wasn't usable in reality, which we saw and were able to communicate to the other partners and the owner of the building by using the viewer feature in Autodesk Docs. By using the 3D viewer, they were able to see it, to evaluate it and to draw conclusions – finding a new way forward and adapting the design.”

“For the owners on our projects, the platform is helping them to understand better what they are getting in advance,” Yasmine explains. “Something that we’ve seen on a few projects is the ceiling height. In design it has been proposed to a certain level, but when they see it digitally, they realise that actually they wanted to be a bit higher. So they catch it at the time when we can still make the change.”

In general, Vanhout has found design issues are being registered more thoroughly, meaning they can be addressed before execution.

Yasmine points out that subcontractors have also been better prepared thanks to BIM. “With subcontractors, it's also a good thing to be able to walk through the models. What do we expect from them? What is going to be difficult? In the parts they’re building, for example, what's reachable? What isn't reachable?”

Being able to create a dynamic site accessibility and logistics plan has also helped Vanhout support its subcontractors’ success.

“We try to evaluate the model during different times, to see how the site will evolve, making sure everything is reachable and practical for the different persons involved – for example, if the cranes are placed correctly. And that's also been a great communication tool. Subcontractors are able to look at it, to evaluate it and give their feedback to make our construction sites work better.”

With 20 projects now live in Vanhout’s Autodesk Construction Cloud environment, the team can better monitor and ensure quality from design through to handover. Owners have a clear picture of the final product from day one, and subcontractors know exactly what they can expect on site. Vanhout’s implementation of BIM across the business has already been a success, and the next steps are set to make work even easier and more efficient for everyone involved.