Wearable technology isn’t just about smartwatches that can monitor your daily steps and vital stats. Wearables have also made inroads in the construction industry and are proving to be valuable tools that can keep workers safe, improve efficiency, and make jobsites more accessible. Needless to say, they’re revolutionizing the construction industry as we know it.

“There’s a whole wearable component that’s centered on data analytics, which comes to the cloud and provides you with insights and immediate alerts. So it’s more than just the hardware.”

- Niran Shrestha, Kwant

You can also listen to this episode on Apple Podcasts, Spotify, Stitcher, YouTube, and anywhere else you get your podcasts.

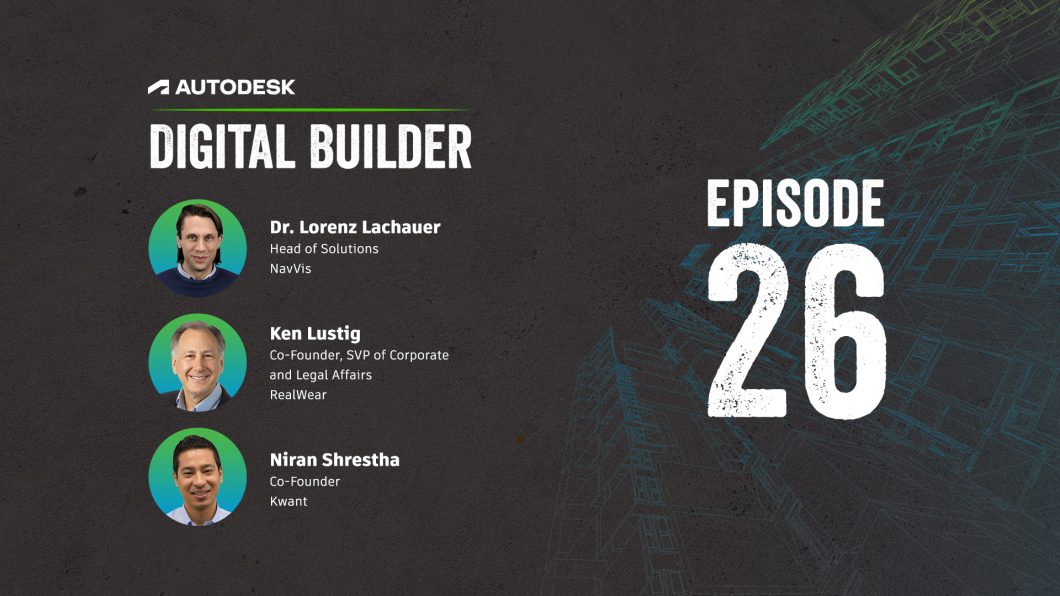

Dr. Lorenz Lachauer, Head of Solutions at NavVis, Ken Lustig, Co-Founder, SVP of Corporate and Legal Affairs at RealWear, and Niran Shrestha, Co-Founder of Kwant, join the show to talk about the benefits and use cases of wearables in construction.

We discuss:

Wearable technology comes in many forms. At a general level, a wearable is “any form of technology that is physically worn by the user,” explains Ken.

Wearables collect data from the user and the surrounding environment, providing actionable insights. Most devices offer improved communication, data collection, and worker enhancements.

In the case of RealWear, Ken says the company provides headworn Android computers that enable workers to have two-way video calls, take notes, and run different applications using voice commands.

Meanwhile, Kwant.ai’s devices are centered around jobsite and worker analytics. “There are different kinds of wearables in the market right now. At Kwant.ai, we’re focused on wearables for worker safety and productivity, as well as understanding their health and biometrics to improve their performance,” says Niran.

He adds that devices can have different form factors. “It could be attached to a hardhat, it could be attached to a wristband, it could be on a belt, or it could be on a vest. Basically, the device is attached to the body, so you're wearing it white it’s collecting data then sending it to the cloud to provide actionable insights.”

As with most innovations, there are many myths and misconceptions surrounding wearable technology. Here are some of the most common ones.

One outdated view, says Lorenz, is that wearable technology yields inaccurate data, particularly in the field of laser scanning.

“There’s been this myth around the inaccuracy of mobile mapping devices, and it was believed that wearables weren’t sufficient scanning solutions. But this is not true anymore,” he says.

“Now, with the evolution of the technology, we’ve found that it’s sufficient for most things in the field of construction.”

Lorenz cites a study conducted in 2021, which found that the majority of construction professionals believe that mobile mapping solutions are effective in laser scanning.

“We can confidently say that our mapping is accurate enough for most applications,” he concludes.

Another myth, says Ken, is that wearable tech is “hard to use and is complex or time-consuming to operate.”

But this is far from the truth. Wearable tech devices have become quite intuitive and easy to grasp, as solution providers like RealWear focus on simplicity and efficiency. Because of this, even someone with no experience can get up and running easily.

“Literally, when a new user puts on a row or a headset, they can operate it in a matter of minutes, with little or no training,” remarks Ken.

“And we've seen that with our technology and with other technology as well; it's becoming so easy and simple to use.”

Wearable devices aren’t vanity technology, and their value goes beyond the hardware itself. It’s worth noting that wearable technology can collect valuable data that can be used to improve productivity and make smarter decisions.

As Niran points out, “There’s a whole wearable component that’s centered on data analytics, which comes to the cloud and provides you with insights and immediate alerts. So it’s more than just the hardware.”

He adds, “The data that we collect and the insights that we provide are the core values of the product.”

When leveraged properly, construction wearables offer several advantages—both in and out of the jobsite.

Perhaps the most obvious benefit is they promote safer work environments.

Wearable technology enables workers to complete certain tasks in a safe manner while on the jobsite. They can take photos, view forms, or hop on calls—all hands-free—so they’re able to safely navigate their environment.

“Wearables allow the user to maintain situational awareness while completing their job tasks,” remarks Ken.

“That situational awareness and safety aspect is a really, really big deal in the construction industry because the worker could be in an environment with lots of things going on. They could literally be walking around on the construction site,” says Ken.

Niran adds that the data gathered from wearables can be used to optimize scheduling and ensure that you have the right number of people on site.

“A lot of times in construction, you are actually adding workers or removing workers without knowing how many people you need. You may be cramming teams in a site or you don't have enough.”

He says that you can prevent such scenarios by paying attention to the data provided by wearable technology.

“If you don’t need that many workers in a single zone, you can actually say, ‘Don't come to work’ or ‘Go to another site.’”

This ultimately leads to safer environments because your jobsites are neither overcrowded nor are they short of people.

The technology can also lower costs.

For one, wearables enable remote collaboration so workers don’t have to be on site all the time.

“People can connect via video and see exactly what’s going on. It reduces the number of people on the jobsite and inspections can be done quicker,” says Ken.

As a result, you’re able to save time and resources, ultimately lowering unnecessary expenses.

Wearables make jobsites a lot more accessible, paving the way for hybrid working conditions.

Take mobile mapping, which has "increased productivity during the era of reduced travel," says Lorenz.

"Our technology allows us to remotely visit construction sites without being physically there," he adds.

Beyond that, wearables can also help teams remotely collaborate and exchange information in real-time.

“With these wearable computing technologies, we’ve seen remote workers push information to the jobsite or provide instructions or live annotation. They can also sign off on additional inspections or assist with other tasks—all while being located someplace different,” says Ken.

In addition to shedding light on the benefits of construction wearables, the podcast also covers actionable guidance on what to consider when implementing the technology. Ken, Lorenz, and Niran weighed in on topics like ergonomics, safety, and other factors to consider when adopting wearable technology. Plus, they shared their predictions and views of where the industry is heading in the near future.

Autodesk’s construction podcast, Digital Builder, is hosted by me, Eric Thomas. New episodes of the Digital Builder podcast go live every two weeks.

If you’d like to take an even deeper look at wearable technology in construction catch the full episode of Digital Builder to learn more.

Listen to the Digital Builder Podcast on: