The headquarters of Triodos Bank near the Driebergen-Zeist has some very distinctive features. The building sits beneath the tree line to respect local bat flight routes and hosts drinking pools for deer and sand heaps for badgers.

With over 3,000 square meters of solar panels, a rain-collecting grass roof and vehicle2grid electric car charging, it’s plain to see that the office is very environmentally-conscious.

But the building has another significant, if less visible, green feature: a material passport, which tracks every component that was used in the construction. That’s because Triodos Bank is designed to be the world’s first completely demountable office, so that every element can be reused.

There will need to be significant changes in the construction industry, if the government is to meet its target of a fully circular economy by 2050. As a result, the concept of the material passport – a digital record of the characteristics and value of every material used in a building – is gaining traction in the Netherlands.

Fortunately, there are significant advantages for construction firms that begin their journey to the circular economy now – and technology can help.

Thanks in part to the production of building materials, the construction industry is one of the biggest contributors to carbon emissions in the world. In the EU, the sector accounts for a staggering 40% of final energy consumption and 36% of CO2 emissions.

Materials are normally used only once, in a model that’s not only environmentally unsustainable, but is a waste of money. Estimates suggest that the average residual value of a building’s materials is 18% of the original project cost – which is usually lost during refurbishment or demolition. In Amsterdam alone, it’s estimated that 2.6m tons of materials, worth €688m, are released each year.

With the Dutch government targeting a 50% reduction in raw materials over the next decade – on the road to a fully circular economy – it’s time to rethink how materials are used in construction.

A major barrier to reusing the materials in a building is simply knowing what they are. As innovator Thomas Rau said, “waste is material without an identity.”

This is where technology can help. A material passport is a digital record of the characteristics and value of every material used, based on BIM data. This record is registered on a database for future use. To date, Madaster – Rau’s company – has collated a public database of resources containing over 2.5 million square meters of logged building materials.

This model has official support. The government has introduced tax incentives for project developers that register material passports and will include circular criteria on all public procurement by 2023. It’s therefore important for construction firms to be ready to adopt the material passport into the lifecycle of their projects.

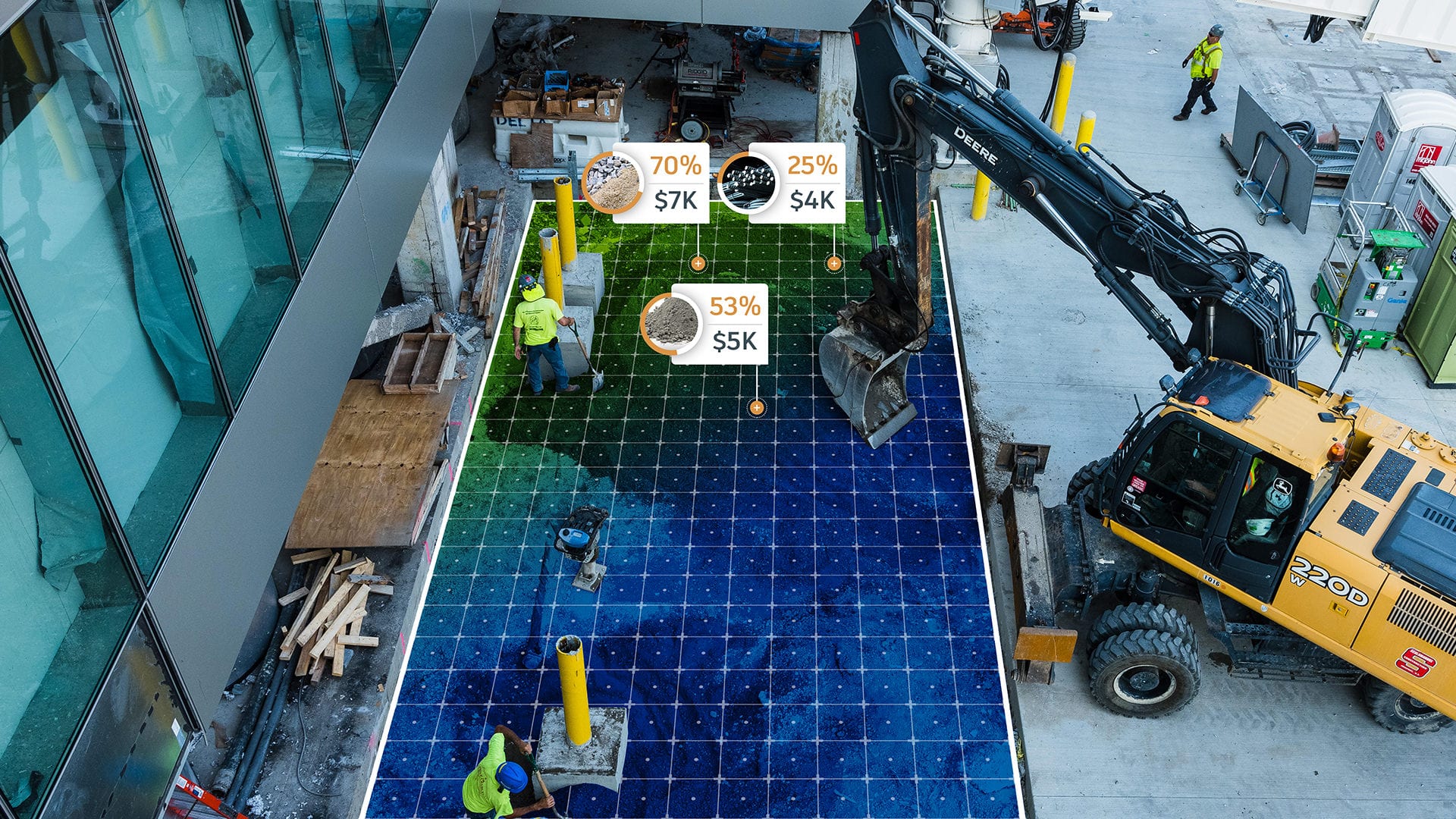

Construction firms can use technology to both deliver material passports and embrace more sustainable practices across the building lifecycle. Tools like Assemble seamlessly extract data on all the components and raw materials contained in a BIM model, to inform material passports. These inventories are linked to a model viewer, so it’s even possible to visualise the materials on the site.

Digital tools also help to ensure that no resources are wasted during the build itself. Collaboration software like PlanGrid enables teams to access up to date information from the site, to build right first time – and avoid wasting materials and energy on rework. The advanced issues management tool also ensures that close out is completed thoroughly and that the digital record accurately reflects the final build.

Finally, digital collaboration tools can also help firms to adopt new, sustainable construction practices. Modular construction, for example, uses less energy and produces components that can be easily extracted and re-used elsewhere. Collaboration software can help firms manage the installation and quality management of these modules – to embrace this sustainable method today.

The need to re-use building materials will only grow, as the population increases and resources become scarcer. As the Green Transformable Building Lab says, to realise a circular economy we need to reach a place where “waste is considered a design error.”

There will be many new innovations on the road to 2050, but firms can begin their journey to the circular economy today. With digital tools, construction firms can adopt more sustainable building practices early, meeting growing demands from public and private sector clients – and enjoying increased efficiency across their builds as a result.

Read more about embracing sustainable construction in our blog on another flagship sustainable development, the Bloomberg offices in London.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.