Daiwa House Industry Co., Ltd. is developing a range of construction businesses, not only in single-family house building as seen in TV commercials, but also rental housing, commercial and distribution facilities, medical care, and nursing care facilities. Behind these promising developments is the enthusiasm of young employees and site managers, and the “Digital Construction Project” that supports them. For this issue, we interviewed Mr. Kazuaki Ishizawa, General Manager, Yokohama Branch, Kanto Construction Works Division of Daiwa House Industry, and Mr. Yoshinori Shimizu, who is working in Construction Works Department I in the same division. We asked them about the present and future utilization of PlanGrid

Daiwa House Industry is diversifying its business, from construction to the management of single-family homes, condominiums, commercial and distribution facilities, hotels, and other areas. The Kanto Construction Works Division led by Mr. Kazuaki Ishizawa is in charge of commercial and business facilities, which means that it engages primarily in the construction of distribution facilities, stores, elderly care facilities, and hospitals. It is one of the leading divisions within Daiwa House Industry. The huge number of construction units underlies the strong performance of this division.

“As far as I know, when compared with other construction companies, our company constructs a huge number of buildings. I think one of the reasons for this is that our contract amount per building is more affordable than other companies. On the other hand, even while constructing a large number of buildings, we ensure that we are always able to deliver consistent construction quality management and control to our clients.” (Mr. Ishizawa)

In order to consistently deliver high-quality buildings to our clients, it is certainly important that individual workers improve their skill levels through experience. However, from the perspective of the company as a whole, instead of depending on the technical capabilities of individuals, the company believes that the power of digital technology is important in terms of developing technical expertise.

Going forward, in order to continue our successful development as a company, organizational technological capabilities should be emphasized over individual technical abilities. —Mr. Kazuaki Ishizawa

“Going forward, in order to continue our successful development as a company, organizational technological capabilities should be emphasized over individual technical abilities. ‘Digital Construction Project’ started with this concept in mind under the direction of the President and CEO. The use of technology and the standardization of these techniques lie at the heart of this project.” (Mr. Ishizawa)

Autodesk, with whom Daiwa House Industry maintains a strategic partnership, introduced PlanGrid to Mr. Ishizawa, who was assigned as a project member, as one solution to promote the digitalization of construction sites. Mr. Ishizawa’s impression of PlanGrid was that it seemed to be “a very promising and deep solution.”

“PlanGrid enables us to inspect and check the site, store the site conditions, and immediately share and view the necessary information with all the concerned parties. Furthermore, it enables us to send necessary information to the people in charge both in and outside the company in a timely fashion. I immediately felt that these functions could be applied to a wide variety of jobs.” (Mr. Ishizawa)

Mr. Ishizawa initially thought about using PlanGrid to perform completion inspections, which are carried out before a building is handed over to the client. While learning more about PlanGrid, however, he realized that it might not only be useful for quality inspections of completed buildings, but also for overall quality checks, which include checking and recording site conditions obtained from safety inspections and patrols.

“Of course, such inspection operations are routinely conducted. However, each inspection operation has sheets in different formats and is conducted by different departments/sections. I thought that all of these differing formats and data collected by different departments/sections might be able to be coordinated in using PlanGrid.” (Mr. Ishizawa)

Mr. Ishizawa then instructed several members including Mr. Yoshinori Shimizu of the Kanto Construction Works Division to start initiatives for the practical utilization and the introduction of PlanGrid into sites in cooperation with Autodesk. Mr. Shimizu, who is working as site manager, says that he saw the immense potential of PlanGrid from the moment he was introduced to it.

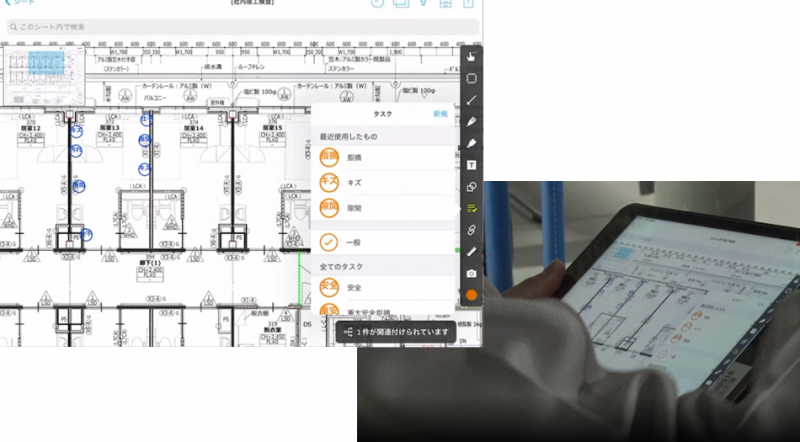

“When using conventional paper documents, sharing information and decision-making took a long time. With PlanGrid, on the other hand, we can share information about the root causes of defects or other findings very easily and quickly if we have a tablet on a site.” (Mr. Shimizu)

When inputting data for the first time using PlanGrid, he realized that PlanGrid would help in on-site decision-making and improve work efficiency, and that it would possibly result in a substantial reduction of time and labor.

“The knowledge of the engineers working on their respective sites will be gathered and stored in PlanGrid, and by doing so, such data can be used effectively in the future.” (Mr. Shimizu)

By utilizing PlanGrid in practice, Mr. Shimizu realized a number of other advantages. He noticed its “usability” at construction sites where people are extremely busy.

“For example, without going to all the trouble of preparing an inspection sheet, the preparations for inspections and safety/site patrols can be completed by inserting a single drawing into PlanGrid. I only need to visit the site and input the site information and photos in the stamps that are on PlanGrid. I do not need to go to the trouble of returning to my office to compile the sheet, and I can finish the work on site. Photos taken on your smart phone can be uploaded immediately. Just by placing the photos in their proper positions on the drawing, there is no longer any needs to send an e-mail to someone else. All the project members can share this information immediately.” (Mr. Shimizu)

Through the introduction of PlanGrid, workers can easily find whether a task has already been finished or is still in progress simply by checking the stamp. They can uniformly manage tasks such as site patrols and safety checks, which would normally require a number of different people to visit the site. Furthermore, there is no need to visit the site; instead, they can check the tasks from the office, meaning that work efficiency will dramatically increase, which will also lead to a drastic improvement in the quality of construction.

“The fact that we can share findings, technical information and prevent problems in advance is significant. This will lead to improvements not only in near-term performance but also in future building quality, which today’s young employees will provide.” (Mr. Shimizu)

The range of uses of PlanGrid is continually expanding. At present, PlanGrid is being promoted for use not only in safety patrols and a variety of inspections, but also for use during pre-construction site investigations.

“Before a site manager is assigned, a supervisor conducts a site investigation. The supervisor investigates the access of vehicles, the conditions of neighboring buildings and surrounding fences, and the infrastructure. I had the idea that PlanGrid might also be useful during such investigations, and therefore, I asked Shimizu to customize PlanGrid so that not only site managers but also supervisors would be able to use it effectively. Preparations for this application of PlanGrid have already begun.” (Mr. Ishizawa)

At present, Mr. Shimizu is heading up the widening use of PlanGrid, and the number of PlanGrid users is continually increasing. However, Mr. Ishizawa is not satisfied with the current state. Mr. Ishizawa hopes for a time when everyone on site will be able to use PlanGrid and will continue steady efforts toward that goal.

“At present, all the members who have a relatively high level of technological knowledge are tackling how to utilize PlanGrid; however, enabling this technology to reach all employees is our next challenge. I think it is necessary that this technology be used by a larger number of workers.” (Mr. Ishizawa)

By gathering and storing the knowledge of different people [in PlanGrid], younger or less experienced site managers can refer to this information easily by searching for a keyword, allowing them to deal with problems quickly on-site. —Mr. Yoshinori Shimizu

According to Mr. Ishizawa, he set a target for the branch offices he manages in Kanagawa, Chiba and Ibaraki Prefectures and made at least two people in each office use PlanGrid on-site. They also have opportunities to share opinions with other members.

“If members who use PlanGrid on the site steadily continue to share their experience with other members, the use of this technology will spread quickly across the company. I am currently working with Autodesk to promote the general use of PlanGrid across the company.” (Mr. Ishizawa)

Mr. Shimizu says that customization (preparation) will be essential to develop the use of PlanGrid horizontally across construction sites.

“We will thoroughly customize PlanGrid so that it will become very simple to use. At first, we will try to reach a level where everyone feels that ‘a job can be completed using only the tools on hand’. By gathering and storing the knowledge of different people, younger or less experienced site managers can refer to this information easily by searching for a keyword, allowing them to deal with problems quickly on-site. Used in this way, the value of PlanGrid will be easily understood by the workers on-site.” (Mr. Shimizu)

Mr. Ishizawa says that he thinks that the utilization of PlanGrid is an investment for the future.

“Up until now, the output differs depending on the person in charge, and this has been covered by the whole staff to maintain a consistent level of quality. Going forward, I am sure that by continuing to accumulate data in the cloud, integrating that data and drawing on it as information, we will definitely be able to increase not only quality stability, but further increase the quality level of staff.” (Mr. Ishizawa)

On the other hand, while Mr. Ishizawa admitted that there are concerns about the future role of technical skills in the construction industry, he says that balancing technology and human skills is the key to moving forward.

“The technical skills that are learned by sweating over your work on-site and by sharing experiences with other skilled construction workers are also very important, because we work with people. We may be able to create a good product using digital technologies, however, we cannot establish a trusting relationship without skilled construction workers. I think that only our people who worked on sites while using digital technology are in the end able to communicate accurately with skilled construction workers. While teaching PlanGrid is important, we should not neglect other kinds of teaching. I do not believe that the Japanese construction industry will completely change in the next five to ten years. However, I hope that the generation following Shimizu will be able to work more easily and enjoyably, while at the same time carrying out consistently high-quality work for our clients. I am engaging in this challenge with considering such thoughts.” (Mr. Ishizawa)

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.