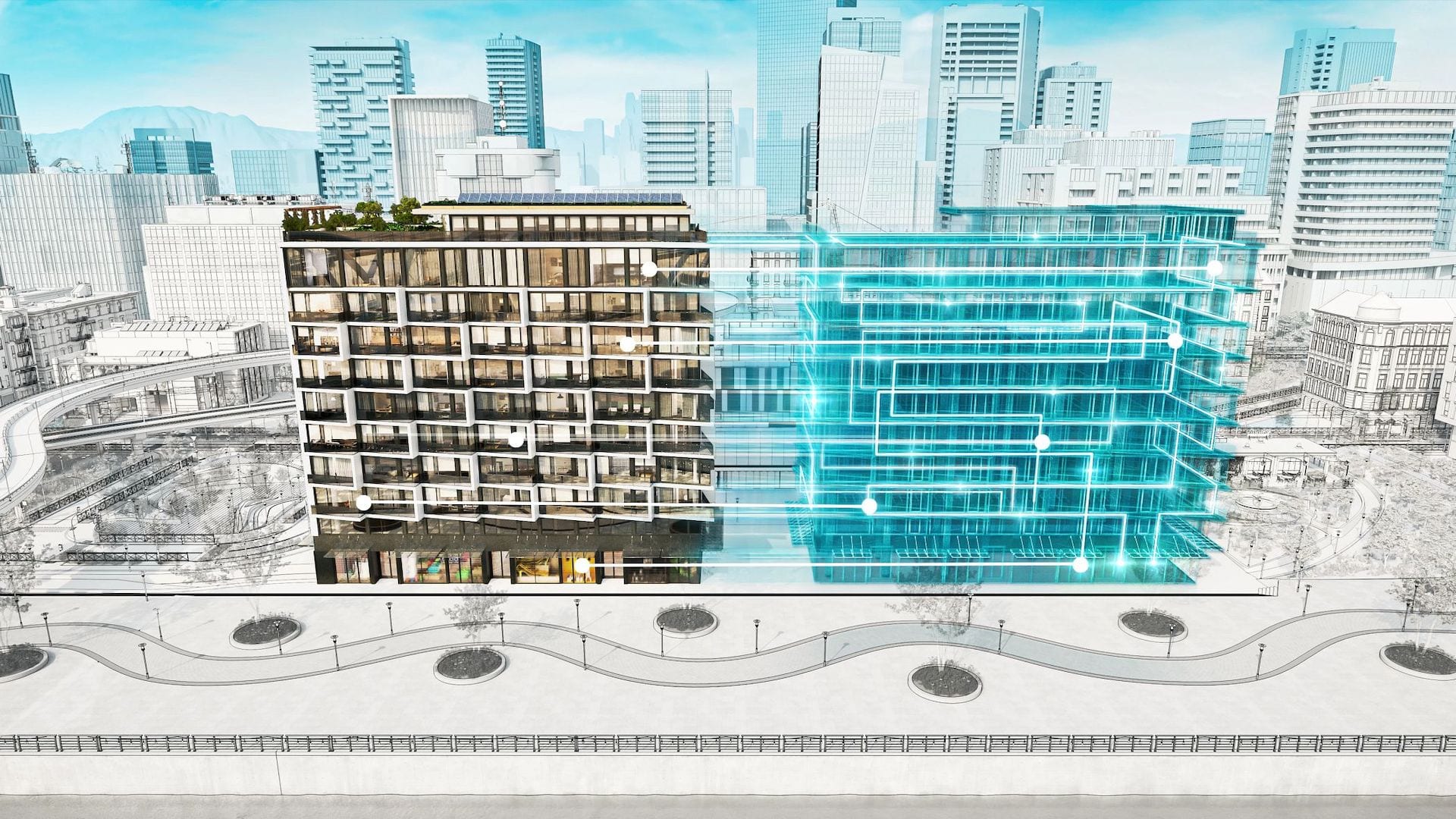

Digital twins, or digital replicas of something that actually exists in the physical world, have become quite a buzzworthy topic in the AEC industry for the last several years. And for a good reason. New technology and innovations are rapidly opening up new opportunities for teams to embrace digital transformation and leverage digital twins in a project’s lifecycle.

To help understand the impact of such innovations, we caught up with Brendan Dillon, the Digital Facilities and Infrastructure Program Manager at Denver International Airport. As someone who has embraced digital twin technology, he has witnessed first-hand its impact on a firm's overall operations.

Brendan recently participated in a webinar hosted by the Construction Owners Association of America (COAA), titled "Delivering the Value of BIM to Owners with the Digital Twin Revolution."

As a bit of a kickoff to this upcoming webinar, we took some time to chat with Brendan about how he got started in the industry, his use of digital twins at Denver International Airport, and more. Here's a look at what all he had to say:

I've been on an interesting career trajectory. I started off as a fine arts student then ended up making a switch to architecture. Then I thought I would be a designer and realized that I wasn't that great at design. But I've always had a knack for software and technology in general, and I became the in-house expert on various aspects of Revit. During the Great Recession, I found myself with a very small firm called Iron Horse Architects. At the time, we were a four-person firm, and I had to do everything. I had to become the Revit expert and essentially the IT department. In six years at Iron Horse, the company eventually grew up to 30 employees, and we landed some major projects with the Denver International Airport (DIA). That’s how I first became introduced to the team at DIA.

I've been on an interesting career trajectory. I started off as a fine arts student then ended up making a switch to architecture. Then I thought I would be a designer and realized that I wasn't that great at design. But I've always had a knack for software and technology in general, and I became the in-house expert on various aspects of Revit. During the Great Recession, I found myself with a very small firm called Iron Horse Architects. At the time, we were a four-person firm, and I had to do everything. I had to become the Revit expert and essentially the IT department. In six years at Iron Horse, the company eventually grew up to 30 employees, and we landed some major projects with the Denver International Airport (DIA). That’s how I first became introduced to the team at DIA.

One of those projects that we did for the airport was the new hotel and transit center. As a part of that work, I was essentially the BIM compliance manager for the design team. I had to review all the content that was coming through and make sure that it was in compliance with the brand-new BIM standards the airport had released. Let me tell you, that was interesting, and it was challenging to meet all of the requirements.

As we were completing the hotel and transit center, the airport posted a position for an internal BIM manager, and I applied. A few Fridays later, I delivered our final package for the hotel and transit center project as an Iron Horse Architects design team member. The following Monday, I received that package as the BIM manager for Denver International Airport. I've been with the airport for seven years this month.

From my perspective, a digital twin is a digital model that is reflective of the existing built condition, containing the information that you need to either operate that facility or connect it to other operations software. We're never going to track asset management data in our Revit model or a digital twin. Still, we are connecting it so that those two systems can inform each other and maximize each other's functionality.

There seem to be two schools of thought on digital twins. One is that the digital twin has everything, and then there's the approach of the digital twin that facilitates everything. I'm more in the second camp. I would say we've been trying to build a digital twin since the day I started. It simply doesn't make sense to do something like BIM or even to be working in the 21st century and not try to build something that facilitates the flow of data across all of your platforms. Unless you've only got a single platform that you're working in, you need to facilitate that data flow. For us, that's integrating our BIM platform with our PROPworks property management information. It's our asset management system, our emergency management system, and our SCADA system. All of it, we're trying to pull together.

It’s highlighted the gaps and duplication we have, both in the data and internal process. Because we didn't have a holistic approach previously, different divisions maintained their own sets of CAD files. If the electrical shop is maintaining their own one-line diagram, that's great. If they're maintaining their own architectural backgrounds, that's a problem. Why? Because they're not necessarily going to get the same information that another shop will get, they all end up looking completely different. So really, identifying gaps and duplications is where we're seeing the biggest benefits at this point in time.

For us, it's all about process evolution. All of our projects have quality assurance (QA) staff who perform inspections on site as part of day-to-day work on that project. Some of them are general site inspections, which consist of making sure the number of contractors on site is what we were told. Others are more specific inspections of welds and systems along those lines.

We had our QA inspectors switch over to a digital inspection tool. And the idea there was to streamline and improve the flow of data. So instead of producing PDFs from a Revit model, then printing those PDFs and bringing the sheets of paper out to the jobsite to make sure they flowed in with anything they were replacing, we were just generating PDFs and posting them to the environment. Then they'd be out on site with their iPads, always with the most current version of the drawings and specs and any change orders.

When we first rolled this out on our test project, we had a lot of resistance. These are old-school folks — literally hundreds of years of experience between them on the team. We said, "Look, this is a pilot. Just give it a try." By the end of the week, they were all knocking on my door saying, "Hey, can I use this on my other projects?" Instead of carrying around a huge roll of drawings, they were just carrying around a single iPad. Instead of having to go back to the trailer to check the spec, they've got the information right on their iPad. They can look at the issue in the field and the spec at the same time.

The time to write their reports was reduced by half an hour a day, which means they spent an extra half hour a day on the site instead of in the trailer writing reports. That's value improvement. The cost reduction on paper is a whole other matter.

And then, when the project is over, all of that information flows back into the common data environment for the facility. We've got all that information available downstream as well.

Don't feel like you need to reinvent the wheel. There are lots of folks out there with good sets of standards. Find a set of standards that seems like it would make sense for you and use it. Don't start from scratch. Start with something that's working for someone else.

Two, don't try to capture everything. If you ask someone, "Hey, what information do you need?" They're probably going to say "everything." That's likely not going to be feasible. Identify the absolute minimum. Get down to the barest bones, start there, and build from that.

And finally, don't be afraid to reach out to other owners. I love talking to other owners. Every time an owner asks me a question, it may be phrased in a way that I didn't think about previously. While I may have an answer to that question at the time, I could have a completely different answer six months later after I've given it more thought. Never stop being curious, learning, and trying to grow.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.