Autodesk Moldflow is a powerful simulation tool that helps guide users in decision-making throughout the injection molding process. By providing critical insights on material selection, process variability, and design modifications, Autodesk Moldflow enhances collaboration between designers and engineers. This ensures more informed choices, resulting in optimized product quality, reduced costs, and efficient production workflows.

Is anyone else shocked to learn that Autodesk’s Moldflow products have the ability to guide its users to make decisions? Probably not! It always seems like Moldflow analysts find a reason not to do this. Autodesk Moldflow is well respected and known as the world’s leading simulation for injection molding. Look at how Moldflow has evolved over the last 5-10 years. More importantly, it has grown beyond analysis and into detailed decision making. Let’s get started with a couple simple examples:

Making material decisions

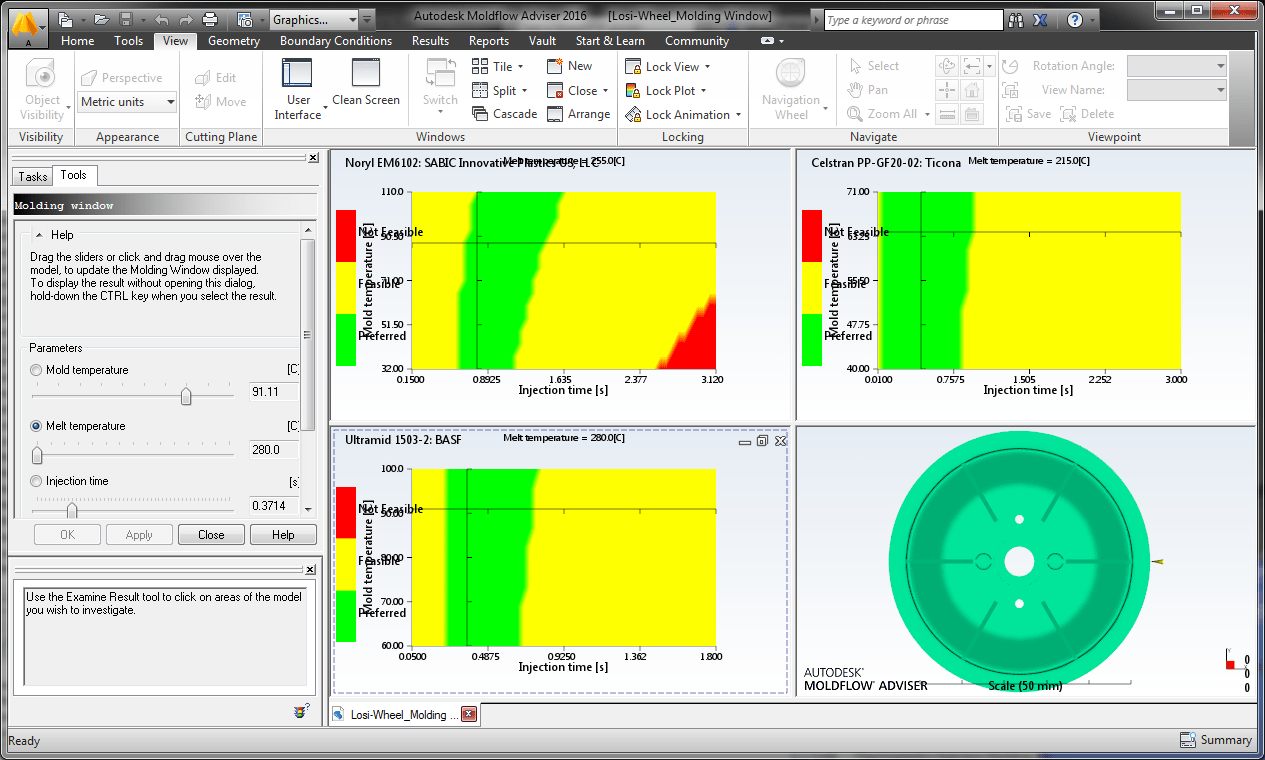

Autodesk Moldflow provides design and analysis level information, all based on the same core technology. So, it’s really not a surprise to hear that both Autodesk Moldflow Insight an Autodesk Moldflow Adviser has the same core technologies, and even very similar outputs. What isn’t really a shock is hearing that not everyone uses, or even knows, about some of our design and engineering level analyses. The Autodesk Moldflow Molding Window Analysis is one of the most underutilized capabilities in Moldflow. And this functionality is available in both Moldflow Adviser and Moldflow Insight.

Imagine you have three materials available to manufacture a product. How do you choose, maybe even if those materials all exist in the same family of polymer? They should all function the same, right? Maybe we just pick this cheapest one? Or the one that we use the most of?

One important lesson about materials is that not all materials are created equal. While many materials have similar properties, sometimes the way they achieve those properties are wildly different. This does not mean one material is better than another. They often get created for specific applications and uses. When working through a new design, having information like energy usage, processing window, part quality, and cycle time matters. It can make the difference between good and better. A material 2% more expensive might save 10% in cycle time. Upfront analysis, like the Molding Window, shows material implications. This enables designers to select materials and alternatives early in the design phase.

Making process decisions

Autodesk Moldflow Insight has been the leading simulation software for plastic injection molding, for as long as I can remember. Injection molding is an extremely difficult process to replicate on a day-to-day basis, and even more so when discussing what it will take to accurately simulate this process. For anyone that has spent any time in this market, the conversation of material variability, process repeatability, and “mold safe” dimensions are all common. What this means though, is that these variations are not only common, but accessed. So, how can simulation software accurately replicate reality when reality is inconsistent? The answer is quite simple: test the variability of the mold!

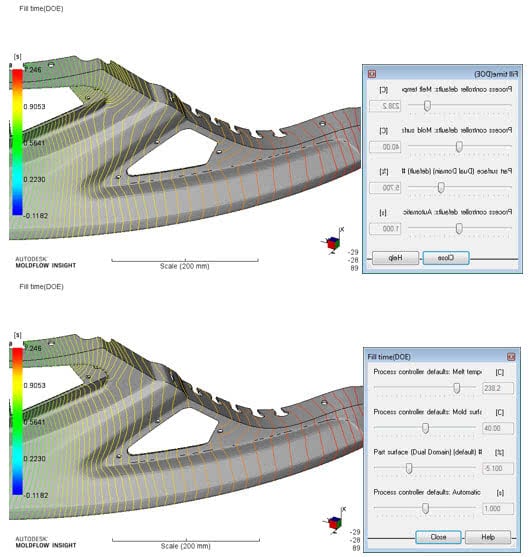

As the mold design progresses, we can use the Design of Experiments in Autodesk Moldflow Insight to run more variability tests and determine the impact of variation. Something as simple as cutting a mold “steel safe” can mean a drastic change to the melt front during injection. In one particular application, a weld line movement was so extreme that it was the difference between a good part, and scrap:

This challenge intensified because the required variation could not meet the quality criteria for this part within mold tolerances. Finding this before mold construction means building a told that can produce a quality part, or having to spend months and money modifying a this mold to make the part “better”.

Using Design of Experiments isn’t just about finding problems, it’s also about understanding your process. Since weather can change, molds and materials change, and even our injection molding machines can have some inconsistencies, at times, knowing which of these are influential to a part can be critical to understanding the quality of any part.

When we understand that melt temperature is critical for maintaining part shape, we can set alerts and limits on injection molding machines to ensure compliance. We can also modify parts to be less sensitive to changes or help establish realistic manufacturing expectations.

For the first time, we can find answers by showing variability, illustrated live and in real-time for anyone to see. We can dynamically show the impact on the part and the results of changes.

Making geometry decisions

Moldflow Insight now includes incredible capabilities that make understanding part design more vivid. Typically, designers and Moldflow Adviser discussions reserve these features.

I know that Moldflow Adviser has always been the simulation tool thought to be the most “upfront” and “designer driven” analysis package. That has become even more clear recently, with many companies starting to implement Moldflow Adviser with CAD Designers. Not just for its ease of use, but its dynamic help and adviser capabilities.

These functionalities of Moldflow Adviser have given to the ability to understand how designs influence manufacturability, how designers can influence designs early, and how to understand what changes are appropriate to resolve a manufacturing problem.

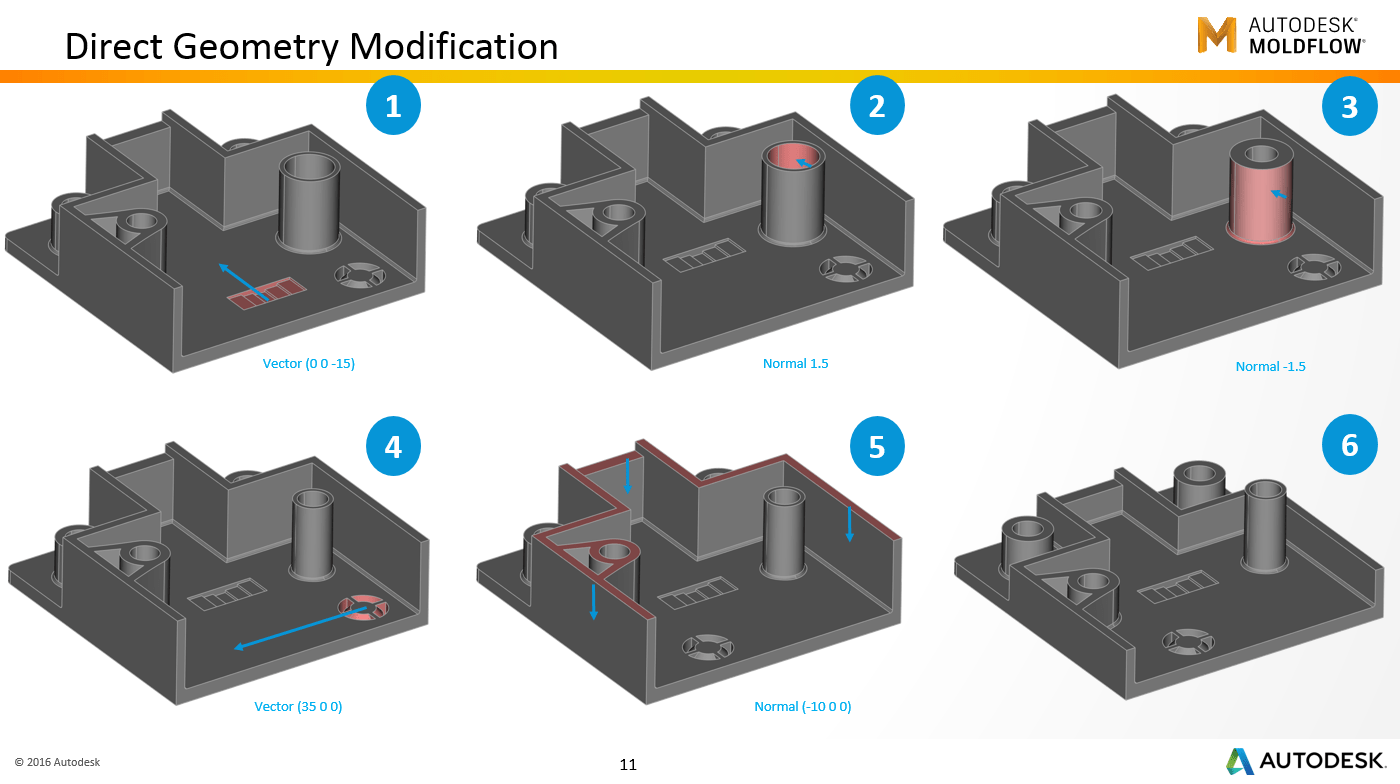

Beyond this point, Moldflow Insight has also added new CAD modification capabilities and now couples them with an automatic mesher, completely automating the design modification process for simulation. While not full CAD functionality, it allows for basic CAD manipulations and modifications.

So, with a practical application, we can take a feature of any part, and show how the modification of the feature can influence manufacturing, part quality, and process capability:

This means understanding designs, optimizing, and making changes within the design’s scope. It also means clearly explaining how changes and variations impact production.

Making engineering decisions

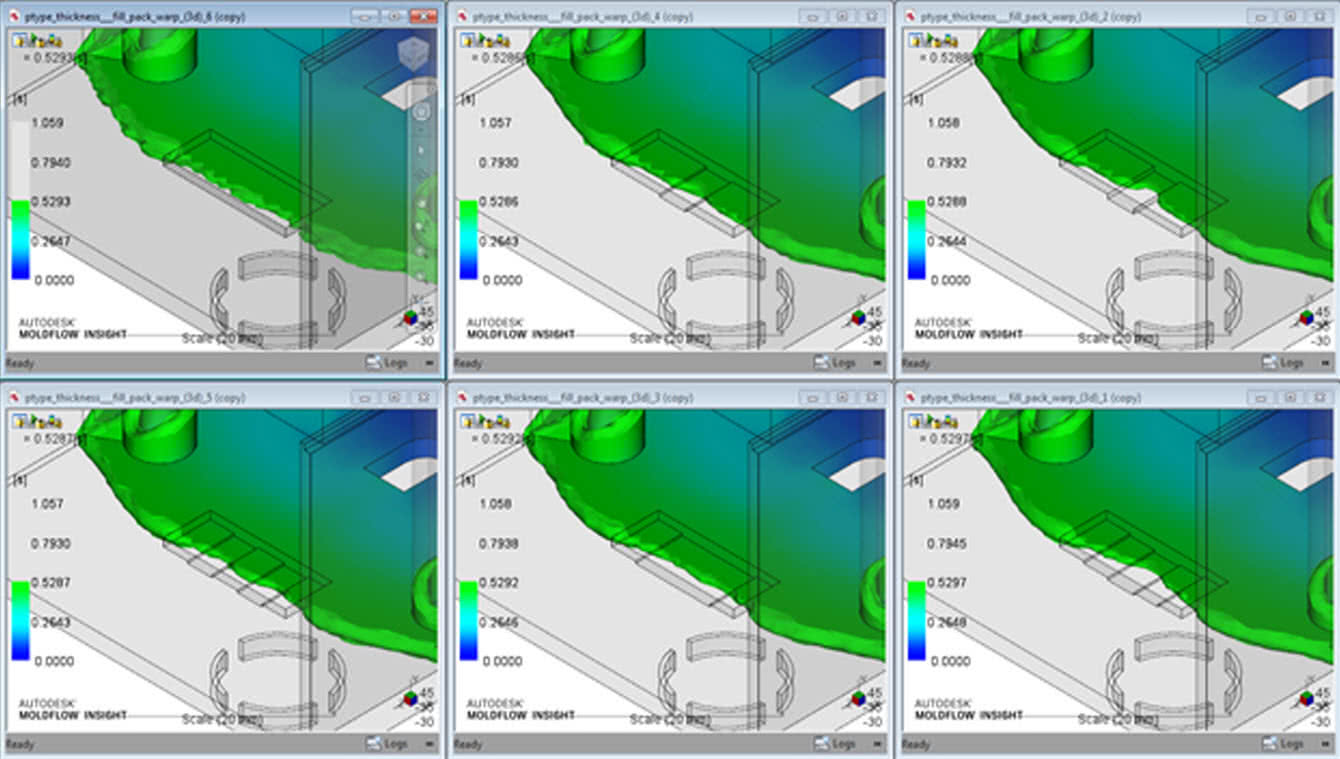

Users have long known Autodesk Moldflow as a simulation product for a single moment in time. It’s been common to apply one set of processing conditions to a nominally designed part, using ideal material information. While this provides users with superb information, the future of Moldflow lies in making engineering decisions.

Autodesk’s “Power of Many” allows automatic simulation of multiple iterations using Cloud Computing, HPC, and mass computing. Leveraging this power, along with DOE and optimization, enables simulations to display results with clear visual imagery. This will transform how simulations impact the plastics industry. It will also revolutionize how we communicate about processes and the industry.