Moldflow simulation enhances collaboration in product development by providing critical insights into design and manufacturing. Moldflow Communicator is a free viewer that allows users to share simulation results easily across teams. This tool facilitates effective communication without costs or interoperability concerns.

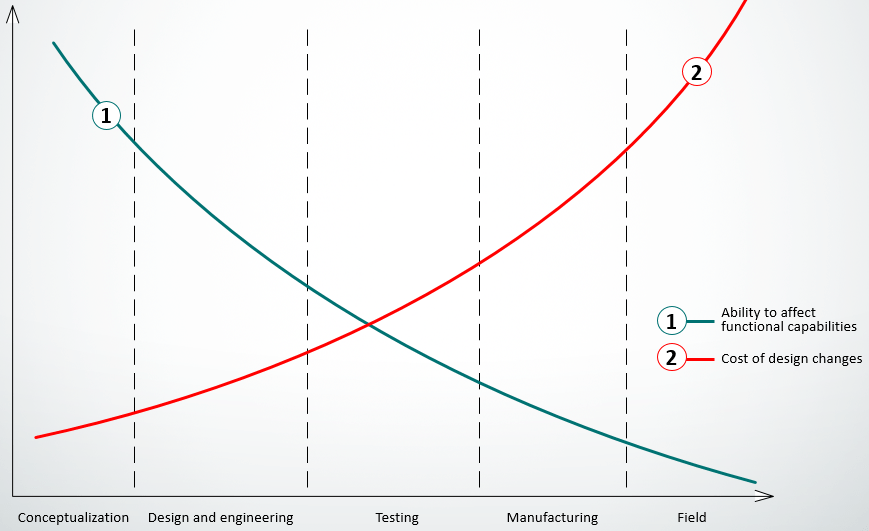

Efficiently working to produce high quality parts at low costs and in short cycles requires effectively communicating between all the groups involved. This includes designers that may lack knowledge on end use function requirements or manufacturability or engineers without an eye for aesthetics. In all these cases, being able to not only communicate those requirements but justify decisions via data driven discussions is essential to minimize downstream costs seen that can range from material waste in process optimization or stabilization all the way through complete retooling.

Moldflow Communicator

Moldflow simulation is a valuable tool that allows all phases of the process to be simulated up front. This ensures efficient designs, optimized processes, and functional capabilities that meet design requirements and end-use tolerancing specifications. However, these simulation tools can be expensive and require expertise in both use and interpretation. This makes their access at all product life cycle levels both uncommon and underutilized. Consequently, this leads to difficulties justifying design modifications and costly production ramp-up processes. In the worst-case scenario, tool reworking can delay production and cost thousands of dollars.

Watch FADO leverage Moldflow to reduce cycle times

Read About Asahi Kasei using Moldflow to reduce waste

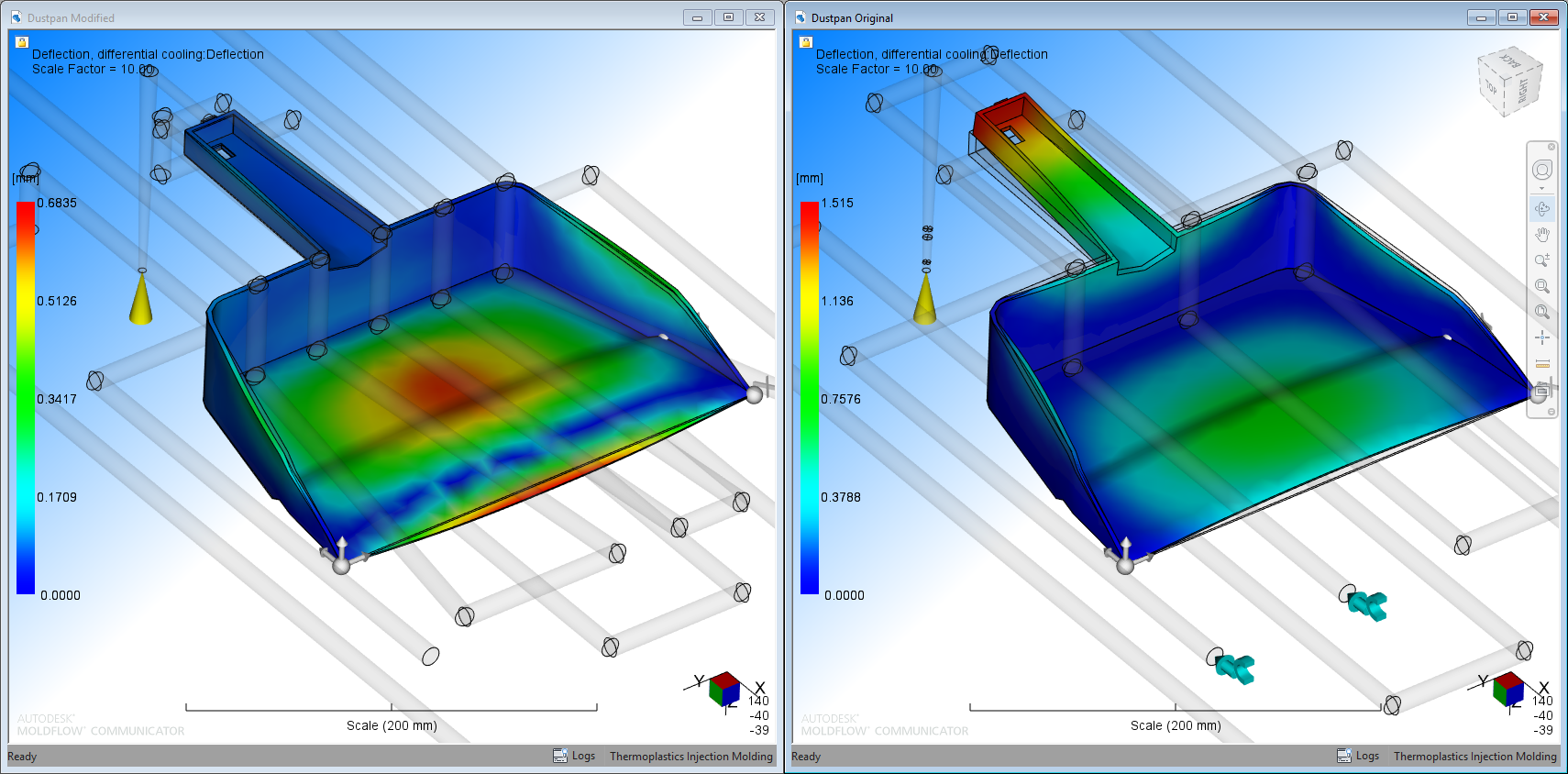

Moldflow Communicator is a free viewer that allows Moldflow simulation results from any phase of your product cycle. These results can be shared quickly and easily with others. This feature allows the engineering group to share design feedback with designers. They can visualize and understand the results more effectively this way. The processing group can relay information on an optimized process. All of this happens without any costs or concerns about interoperability of products.

This allows multiple designs to be compared, processing information and results to be shared, and problems on all front to be addressed in a light-weight, easy and free to access program. In all collaboration becomes easier, allowing more time for new designs, new processes, and faster time to market. To learn more you can review information available on Autodesk Knowledge Network.