Surgical Site Infections (SSIs) are a major concern in operating rooms, prompting a need for improved air quality. Enter Computational Fluid Dynamics (CFD), a groundbreaking technology that transforms our understanding of airflow! Using scalar mixing analysis, we can simulate how clean air circulates, eliminating stagnant zones and ensuring optimal conditions for surgery, ultimately enhancing patient care and safety.

Surgical infections due to airborne bacteria are an area of concern for doctors, hospitals, and patients. According to a 2002 paper published in the Journal of Surgical Research, researchers found that 2.6% of all operations were complicated due to Surgical Site Infections. Traditionally, hospitals have deployed industrial high-efficiency particulate air (HEPA) filtration systems to supply operating rooms with clean air that adheres to strict CDC standards.

While these initiatives have proven to decrease the chance of SSI’s, many unknowns still exist.

- How long after a patient enters a room and HEPA filters are turned on can surgery start?

- Are there areas in the room prone to air stagnation? If so, is the location in a critical area?

- What effect does adjacent room leakage/air quality have on operating room air quality?

Irregular room dimensions, retrofitting existing operating rooms, and tightly packed surgery schedules have led to a need for a better understanding of operating room air quality. In recent years CFD has been leveraged to better understand, predict, and improve airflow in operating rooms.

This transient scalar mixing analysis simulates the cleaning, or flushing out, of a dirty room from time = 0. This is similar to some surgical patient or hospital personnel entering a vacant operating room, then turning on the HEPA filtration system and waiting for the room air quality to reach an acceptable level to begin surgery. This analysis will be done using a scalar mixing analysis.

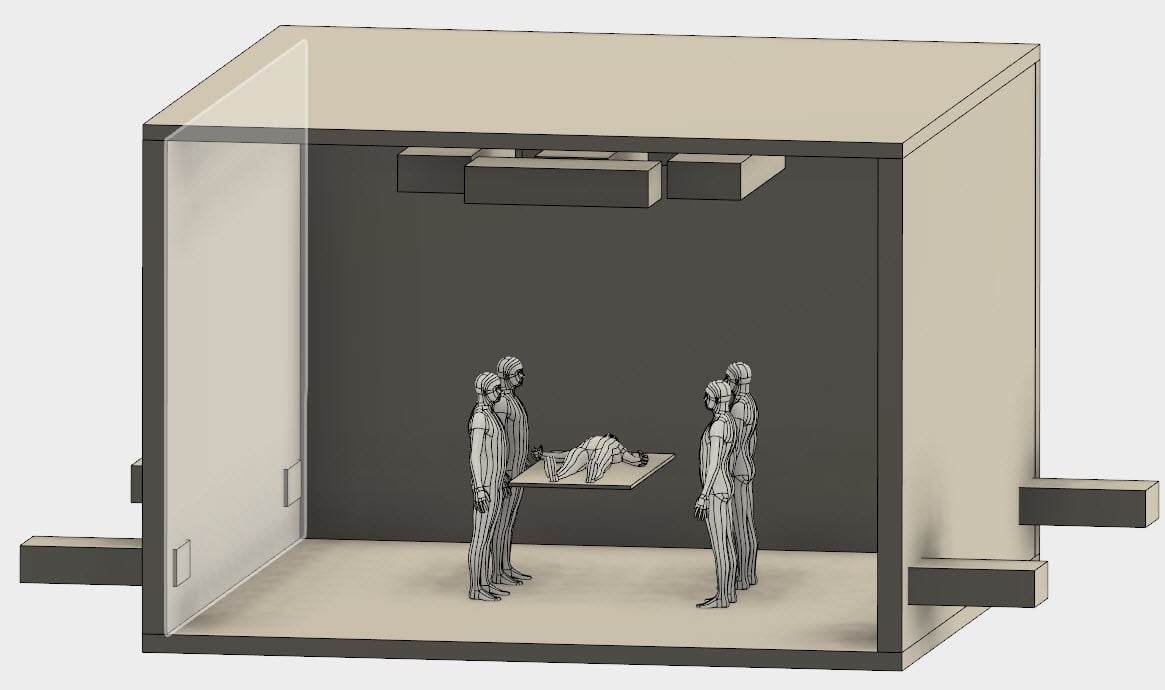

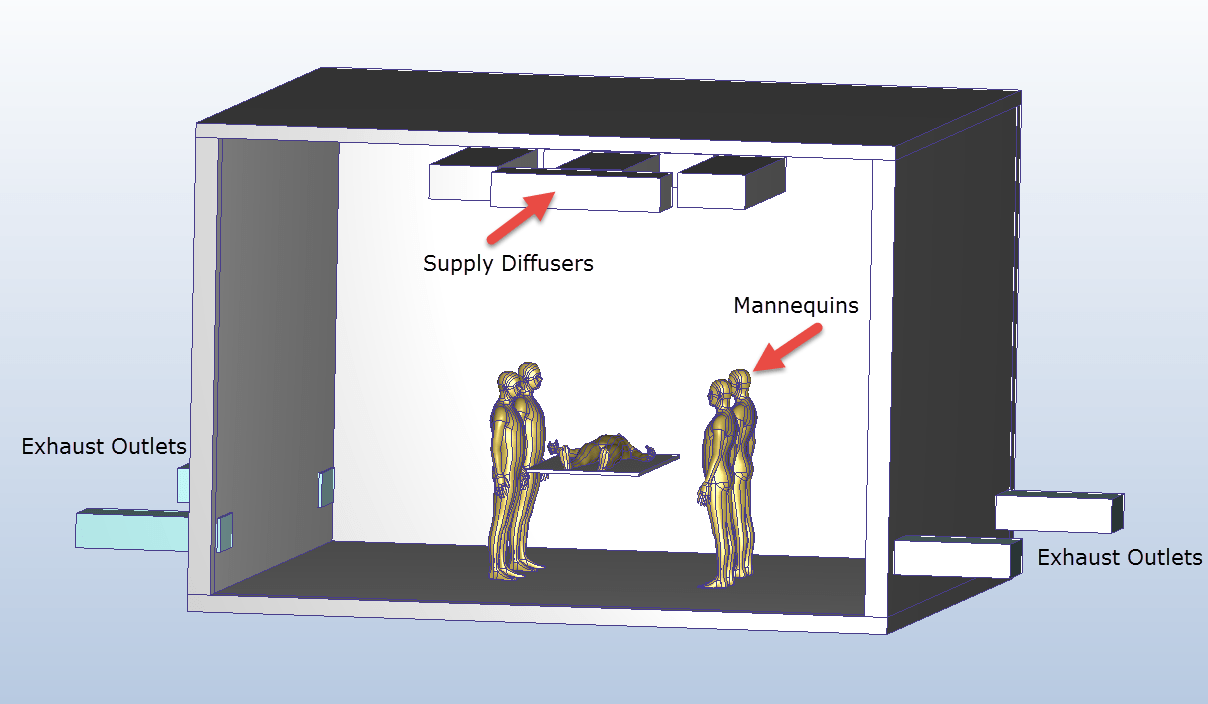

CAD model:

This CAD model consists of an operating room table, 5 air supply diffusers, 4 outlets, and 5 mannequins.

Operating room in CAD:

Materials:

Assign the internal volume as air. Assign the walls, diffusers, and operating room table as steel. Suppress the solid materials from meshing.

Materials in Autodesk CFD:

Initial conditions:

| Location | Initial Condition |

| All air volumes | Scalar = 0.2 |

Boundary conditions:

| Location | Boundary Condition |

| Supply Diffuser 1, 2, 3, 4 | 100 l/s, Scalar = 0.01 |

| Supply Diffuser 5 | 400 l/s, Scalar = 0.01 |

| Outlets | 0 Pressure Gauge |

The scalar values are arbitrary and scaled to industry standards. The initial condition of scalar = 0.2 represents dirty air. The boundary conditions of supply air with a scalar of 0.01 represent clean air. In this particular situation, air which has a scalar quantity of 0-0.05 is considered clean.

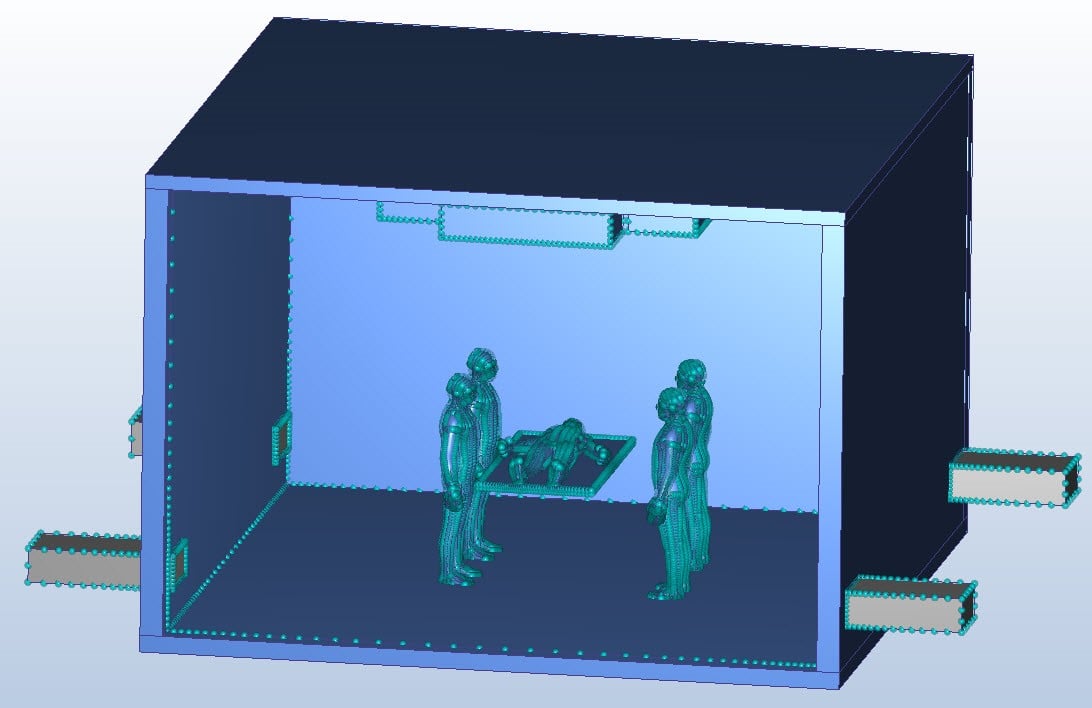

Meshing:

Suppress all walls and diffusers, along with the operating table and mannequins. Use an automatic mesh with surface and gap refinement for this model. After an initial autosize, refine the sizing by selecting the air domain and changing the size adjustment bar to 0.7. Apply a refinement region below the diffusers.

Mesh in Autodesk CFD:

Solve:

Set the Solution Mode to Transient via the Solve dialogue box. Use a 0.25-second time step along with 3 Inner iterations. Set the Stop Time to 240 seconds. Enable the scalar module via “Advanced” on the Physics Tab. Set a save interval to record intermediate results every 10 seconds.

Results:

Use an isovolume to visualize where air in the room meets surgical quality. Set the save intervals to 10 seconds. Create an animation showing how clean air enters the room and circulates over the 240-second time period. Each frame represents 10 seconds of time.

Velocity Profile at 240 Seconds: