& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

Dive into the fascinating world of Autodesk CFD and discover the power of Local Mean Age (LMA)! This innovative tool reveals the hidden dynamics of fluid flow, providing crucial insights into how fluids behave in your designs. By understanding LMA, you can optimize performance, identify stagnation zones, and enhance overall efficiency like never before. Get ready to transform your simulations and elevate your projects to new heights!

When looking for a new car, the vehicle’s appearance is one of the first things that attract buyers. Misaligned side panels, a wavy front hood, or depressions on the bumper negatively affect potential buyers’ interest. These issues portray a low-quality product and increase the chances of losing a sale.

This is one reason why upfront engineering is extremely helpful for many manufacturers within the automotive industry. With so many of the visible components of a vehicle now being created with plastic through injection molding, identifying shrinkage (side panel alignment), warpage (the wavy hood), sink marks (the depressions on the bumper) using Moldflow is handy to help manufacturers achieve that high-quality look they desire.

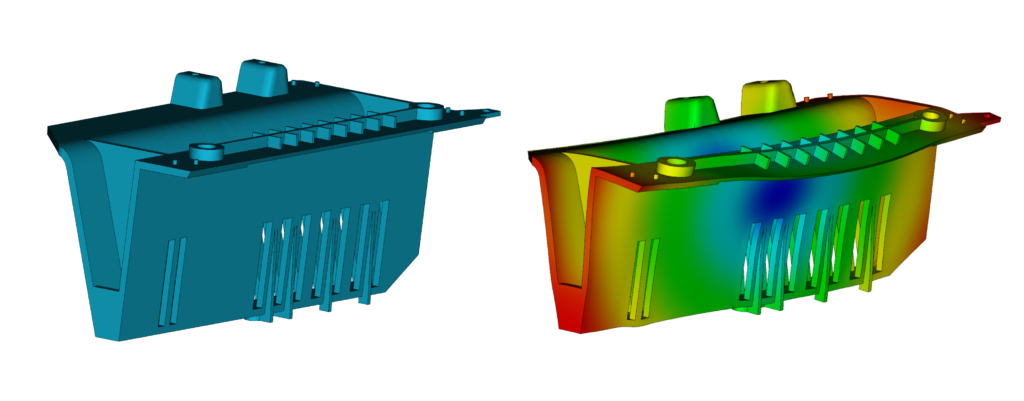

Fill+Pack+Warp

Shrinkage is a key influencer to how a molded part deflects, so the process for investigating and minimizing unnecessary shrinkage includes many similar approaches as addressing part warpage. Within Moldflow simulations, the warpage analysis includes analyzing the shrinkage, but enabling the feature, “Isolate Cause of Warpage”, prior to running the analysis will provide more detailed result plots including a set of results called, “Deflection, Differences in Shrinkage”. These plots display the amount of part deflection due to shrinkage variations. In addition to this plot, other Moldflow results including volumetric shrinkage, shrinkage compensation values, and even the fill result. How the material flows through the cavity (orientation of flow) can help identify where more shrinkage may occur.

Catching excess or unexpected shrinkage through simulation aids mold design. Traditionally, mold designers apply rule-of-thumb values for shrinkage based on general material properties. Moldflow simulation can help make additional steel-safe recommendations to tool designers or provide insights for reducing shrinkage if areas are out of tolerance. Some options for this may include:

Read more about shrinkage in injection molding: Technical Article: Dynamics Affecting the Shrinkage of Injection Molded Parts.

Fill+Pack+Warp

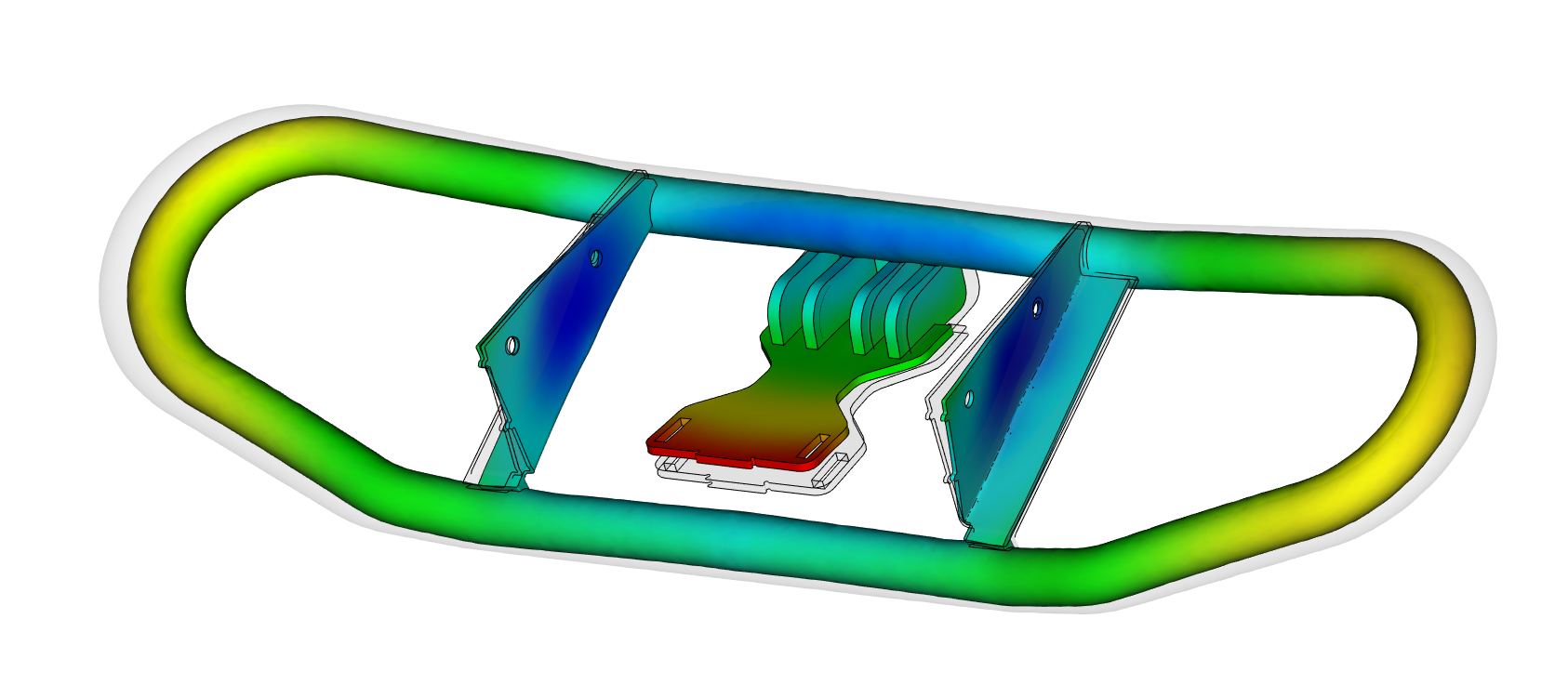

Although Moldflow’s default warpage result plots provide insights into part warping trends, additional plots reveal the full deflection story. Moldflow Insight solves for three main categories that cause part warpage. As mentioned in the shrinkage section, enable advanced warpage result plots before running a Warp analysis by selecting the “Isolate cause of warpage” option. After the simulation completes, review result plots for warpage caused by “Differential Shrinkage,” “Differential Cooling,” or “Orientation Effects.” These plots direct analysts to the main source of deflection. Default result plots like Volumetric Shrinkage and Part Temperature also provide insights into warpage causes.

When reviewing result plots for deflection in Moldflow, identify the main cause of deflection first to reduce warpage. Then, rerun the deflection analysis to see how those changes affect the other warpage plots.

Read more about warpage in injection molding: Technical Article: The Causes of Warpage.

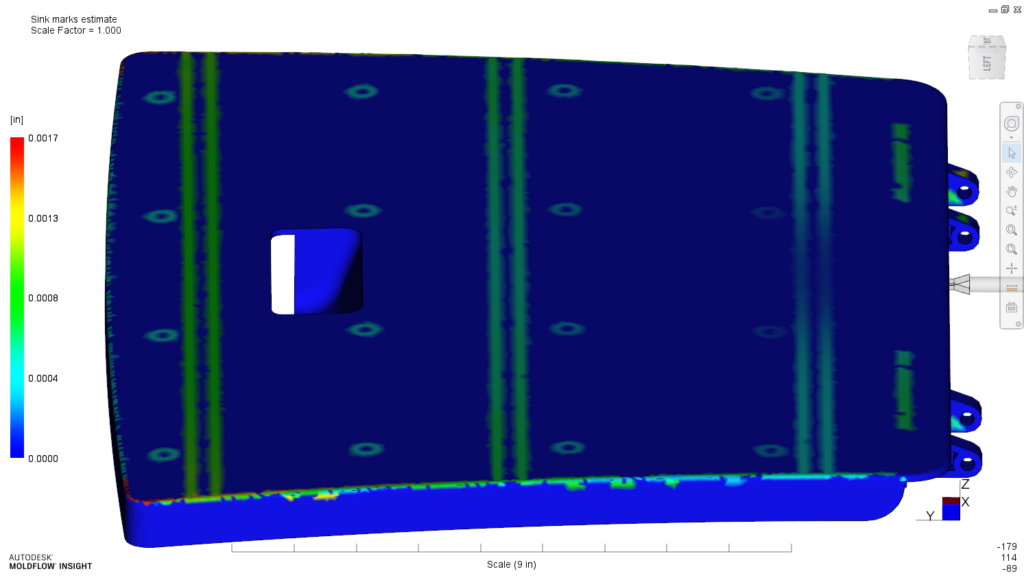

Fill+Pack+Warp

Moldflow’s sink mark result identifies potential part design or processing concerns by predicting material behavior opposite features like ribs. Review built-in sink mark results (Sink Mark, Estimate; Sink Mark Index; Sink Mark, Depth) to find the probability of sink marks and their predicted depth.

For areas not captured by built-in sink mark results (thick regions and non-rib related areas), use other Moldflow results for insight. One example is the Volumetric Shrinkage result, as observing shrinkage differences can hint at voids or sink marks.

Optimizing packing profiles may reduce or eliminate sink marks caused by insufficient packing. A virtual design of experiments (DOE) study in Moldflow Insight can identify if packing pressure resolves sink marks. Select sink marks as a quality criteria factor during set-up. Including melt and mold temperatures in the DOE is also helpful, as some temperatures may affect surface strength for sink marks.

If optimizing packing pressure does not suppress sink mark defects, costly and time-consuming tooling modifications may be necessary for an acceptable appearance. In this case, simulating the following options in Moldflow Insight is ideal. This approach allows you to avoid jumping directly into a tool modification that may fix the issue but could also result in additional problems that need to be addressed.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.