Navigating the complex world of new product introduction can feel like a tightrope walk. As a simulation engineer, I’ve witnessed the chaos firsthand when projects go awry. A seamless process—from designing a product to launching it—should be the goal. However, unexpected hiccups often disrupt this flow, leading to delays and rising costs. In this post, I’ll share common pitfalls I’ve encountered in the industry and effective strategies to prevent them. Let’s explore how simulation can be the game-changer in delivering successful projects.

In my career as a simulation engineer I’ve helped businesses of all sizes to successfully deliver projects by applying CAE software. In this post I’m going to explore some of the most common issues I see, and how to prevent them.

New product introduction is supposed to go like this:

- Design a product

- Make a mould tool

- Produce parts

- Go to market

“If only!” I hear you cry. The process isn’t always as smooth as we’d hope. Hiccups along the way can delay product launch and incur significant unexpected costs. When parts don’t meet specification, it can descend into the dreaded blame game between designers, toolmakers and moulders. Things can get messy quickly, and I’ve seen it happen when all parties are in the same company or spread over all 4 corners of the world.

What defines a successful project?

For me a successful project combines innovative design and the timely delivery of reliable tooling, enabling the cost effective production of quality parts.

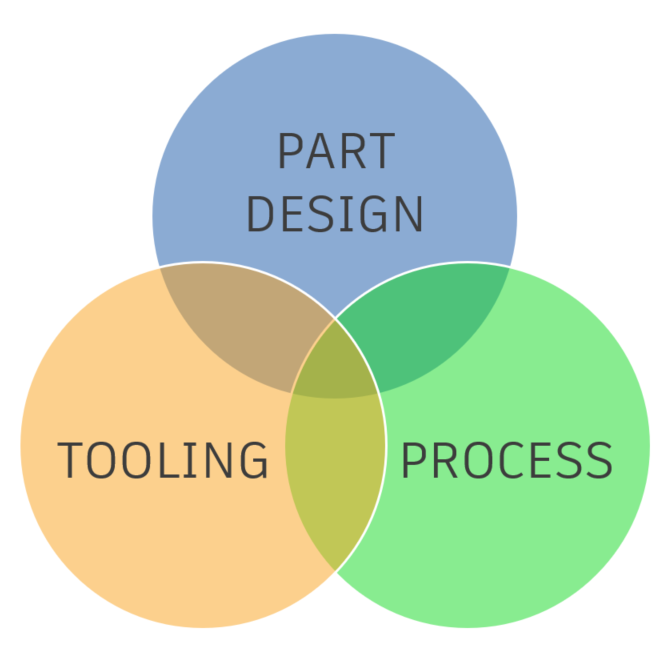

The most successful projects demonstrate effective collaboration between part design, tooling and processing. If we lose focus on any one of these areas there’s a good chance of problems down the line. This is where Autodesk Moldflow comes in, as a unifying thread running through the whole project.

So why isn’t everyone running simulation? I’ve had the privilege of seeing all sides of this discussion – here’s a snap shot.

Part designer

“…it’s up to the toolmaker and moulder to supply me good parts!”

I hear this all the time, and it’s an understandable point of view. You’re paying for the experience and skill of the Toolmaker so why can’t they get on with it? However, having worked on hundreds of injection moulding projects over the years I would estimate that 80% of quality issues are rooted in the part design. Integrating simulation into the design process can achieve huge improvements in product quality, reduce costs and accelerate product launch.

A common fear for a Designer is taking on ‘too much responsibility.’ For example, you might worry that specifying a gate position will lead others to blame you for any moulding problems. This comes down to ensuring a collaborative working relationship. Always listen to your Toolmaker’s recommendations, but make sure they are justified and ideally validated with simulation.

Toolmaker

“…whenever I find problems with the part design its always “too late to change that”!”

What’s the point in running simulation when the end customer doesn’t act on the findings? This frustration often arises when the project engages the Toolmaker too late. If the team views Moldflow analysis as just a ‘tick box exercise,’ then the product development and delivery strategy needs to change.

As a Toolmaker you have a difficult job; juggling tight tolerances, feed system design, ejection, venting, robustness and cooling design. Make sure you’re up to date with the latest technology and how this can differentiate you as a premium supplier while saving your customers money by, for example, reducing cycle time with conformal cooling.

Process Engineer

“…I’ve got to do my best to make good parts with what I’ve been given!”

Workers on the shop floor often receive their Moldflow invitation last, if they get invited at all. As a Process Engineer, you possess valuable insight into the realities of production and should get involved early on. One example of this is gate size. If a tool arrives with too small a gate, you may need to slow the injection speed to avoid over-shear, which can compromise other hidden aspects of part quality, such as residual stress.

Every Process Engineer should have access to Autodesk Moldflow Communicator; it’s free and will allow you to see what’s actually going on inside the mould. Closing the loop between production and simulation is a fundamental but crucial step – and the one most often skipped.

Golden rule

Communicate. Communicate. Communicate. It’s that simple. If you establish a framework that ensures all voices are heard, you will take care of the rest. If you’re not sure how to start, drop me a message.

Looking forward, the collaborative workflows enabled by Autodesk Fusion will transform new product introduction, so watch this space.