Learn what value stream mapping is, the benefits it can have for your business and how Autodesk design and manufacturing solutions can help.

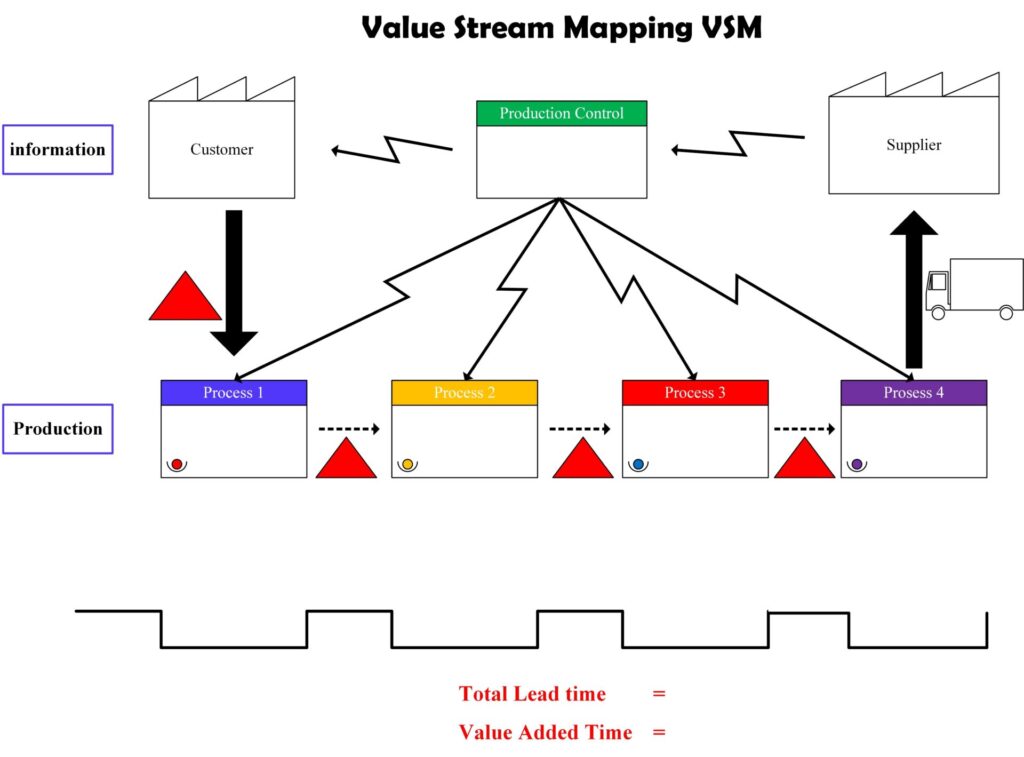

Value stream mapping (VSM) is a lean-management method used to analyze and design the flow of materials and information required to bring a product to market. Originating from the Toyota Production System, VSM has become an essential tool in modern manufacturing. It helps drive efficiency, reduce waste, and enable continuous improvement. This article delves into what value stream mapping is, its importance in manufacturing, its benefits, and applications.

What is value stream mapping?

Value stream mapping is a visual tool that helps organizations see and understand the flow of materials and information as a product makes its way through the manufacturing process. This flowchart-like diagram represents every step in the process, from raw material to finished product, highlighting areas where improvements can be made.

A VSM stream includes:

- Current state map: This captures the existing process flow, identifying each step, the time taken, and any delays or waste.

- Future state map: This represents the optimized process flow, incorporating identified improvements to reduce waste and increase efficiency.

- Implementation plan: This outlines the steps required to transition from the current state to the future state.

The importance of value stream mapping in manufacturing

Value stream mapping plays an important role in manufacturing for several reasons:

- Identifying waste: Waste can take many forms, including excess inventory, unnecessary movement of materials, waiting times, overproduction, and defects. By visually mapping the process, VSM streams helps companies pinpoint areas where waste occurs and develop strategies to eliminate it.

- Improving efficiency: By creating a detailed map of the current state of the manufacturing process, VSM helps identify bottlenecks and inefficiencies. This helps organizations streamline operations, reduce cycle times, and improve overall productivity.

- Enhancing communication: VSM streams provide a clear visual representation of the manufacturing process. Thus, making it easier for teams to understand and communicate about the workflows.

- Supporting continuous improvement: By regularly updating the value stream map and re-evaluating the manufacturing process, companies can always strive for better performance and higher quality.

- Aligning goals and metrics: VSM streams help align the organization’s goals and metrics with the actual processes on the shop floor. This ensures that everyone is working towards the same objectives and that performance metrics accurately reflected.

Benefits of value stream mapping

- Reduced lead times: By identifying and eliminating waste, VSM reduces the time it takes for a product to move from raw materials to finished goods. Shorter lead times mean quicker delivery to customers and a more responsive manufacturing process.

- Lower costs: Eliminating waste and improving efficiency directly translates to cost savings. Reduced inventory, fewer defects, and less rework all contribute to lower production costs.

- Improved quality: VSM streams help identify sources of defects and other quality issues, enabling organizations to address them at their root cause. This leads to higher-quality products and fewer returns or recalls.

- Better resource utilization: By streamlining processes and reducing waste, VSM ensures that resources—whether they are materials, labor, or equipment—are used more effectively. This leads to higher productivity and better return on investment.

- Enhanced customer satisfaction: Faster lead times, lower costs, and higher quality all contribute to improved customer satisfaction. Customers receive their products more quickly, at a better price, and with fewer defects.

- Greater agility: In today’s fast-paced market, manufacturers need to be agile and responsive to changing demands. Value stream mapping helps create a more flexible and adaptable manufacturing process. This helps companies to quickly respond to customer needs and market changes.

Applications of value stream mapping

Value stream mapping can be applied in various areas of manufacturing, including:

- Production planning: VSM streams help in designing efficient production plans by identifying the most effective sequence of operations and the optimal use of resources.

- Process improvement: Value stream mapping identifies bottlenecks and inefficiencies in the manufacturing process, enabling organizations to implement targeted process improvements.

- Supply chain management: VSM can extend to the entire supply chain, helping organizations optimize the flow of materials and information.

- New product development: VSM is valuable when developing new products, helping to design efficient manufacturing processes from the outset.

- Lean manufacturing initiatives: Value stream mapping provides the visual tools and methodologies needed to implement lean principles effectively.

- Quality management: VSM helps identify sources of defects and other quality issues, enabling organizations to implement effective quality control measures.

Autodesk solutions for value stream mapping

Autodesk Inventor and Factory Design Utilities can significantly aid in the Value Stream Mapping (VSM) process by providing comprehensive tools for visualizing and optimizing manufacturing workflows.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

Inventor’s robust 3D CAD capabilities allow manufacturers to create detailed and accurate models of their products and components. This level of detail is critical for understanding the intricacies of the manufacturing process and identifying areas where to make improvements. By simulating mechanical designs and assemblies, teams can foresee potential issues and optimize designs to ensure a smoother production flow. These detailed visualizations support the creation of value stream maps by offering a clear picture of the product’s journey through the manufacturing process, from raw materials to finished goods.

Factory Design Utilities, when used in conjunction with Autodesk Inventor, enhances the VSM process. Together they focus on the layout and material flow within the production environment. This toolset allows manufacturers to design and simulate factory layouts in both 2D and 3D. Thus, providing a comprehensive view of the physical flow of materials and information. By visualizing the factory floor with accurate placement of equipment and workstations, teams can identify bottlenecks and inefficiencies in the current state map and develop optimized future state maps. The material flow simulation capabilities of Factory Design Utilities help in understanding how materials move through the production process. Ultimately, making it easier to identify and eliminate waste. Together, these tools enable a holistic approach to VSM, combining detailed product design with optimized factory layouts to drive efficiency and continuous improvement.

Optimize Your Factory Design Process

Streamline workflows with Autodesk Factory Design Utilities.

Conclusion

Value stream mapping helps transform modern manufacturing by helping companies identify and eliminate waste, improve efficiency, and drive continuous improvement. By providing a clear visual representation of the manufacturing process, VSM helps align goals, enhance communication, and support data-driven decision-making.

Autodesk offers powerful solutions that enhance the implementation of value stream mapping providing advanced visualization, collaboration, and data analysis capabilities. Manufacturers can create more efficient, cost-effective, and agile processes, ultimately leading to higher quality products and greater customer satisfaction.