Explore lean manufacturing its benefits and role in modern production. Learn the importance of choosing the right tools for a lean strategy and how Autodesk Vault and Fusion Manage support these initiatives with data management and enterprise collaboration features.

Lean manufacturing is a production methodology that aims to minimize waste while maximizing customer value. Originating from Toyota, it focuses on systematically eliminating non-value-adding activities, such as excessive inventory, waiting times, and overproduction. The ultimate goal is to create more efficient workflows that enhance productivity and quality while reducing costs.

Read on to learn about lean manufacturing and how Autodesk’s data and management tools allow manufacturers to fully embrace the approach.

Lean manufacturing in the real world

Lean manufacturing offers numerous benefits to organizations by focusing on reducing waste and improving efficiency.

One of the primary advantages is cost reduction. By identifying and removing non-value-adding activities such as excess inventory, overproduction, and downtime, companies can lower operational costs. This streamlined approach also improves production speed, enables faster lead times, and allows companies to respond more quickly to customer demands. Additionally, lean manufacturing enhances product quality by emphasizing continuous improvement. With a focus on refining processes and eliminating defects, companies can produce higher-quality goods while reducing rework and waste.

When choosing a lean manufacturing solution, several factors must be considered.

First, the complexity of the company’s processes should guide the level of customization required in a solution. To ensure cohesive workflows, it’s essential to choose tools that can integrate with systems like product data management (PDM) or enterprise resource planning (ERP). Real-time data access and collaboration is necessary for maintaining efficiency, as they enable teams to make informed decisions quickly. Scalability is another important factor. The solution should grow with the company, continuing to support lean objectives as the organization expands.

Autodesk Vault for centralized product data management

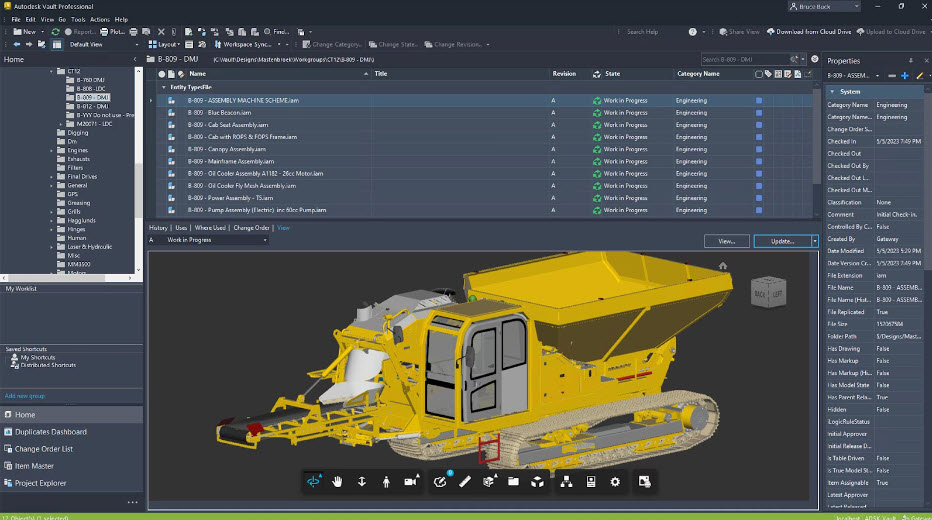

Autodesk Vault is a powerful PDM solution that enhances collaboration and optimizes data management.

Optimize Data Management with Autodesk Vault

Secure, organize, and manage your engineering data efficiently.

By serving as a central repository for all design and engineering data, Vault eliminates the inefficiencies of searching for files, managing multiple versions, and handling outdated data. The CAD-integrated solution integrates seamlessly with Autodesk design software, such as Inventor, AutoCAD, and Revit, making it easier for teams to work with the latest product development data.

Vault supports lean practices through its automation capabilities, such as automated revision control and the ability to track design history. These features guarantee that everyone in the organization is working from a single source of truth with minimized risk of errors and rework—two of the main forms of waste that lean manufacturing aims to eliminate. Vault’s engineering change order (ECO) management process automatically tracks why, how, and when revisions are made along with comments during the design process – which also aligns with lean’s focus on continuous improvement. This provides an efficient way to manage changes without disrupting workflows.

Moreover, Vault’s concurrent design capabilities enables collaboration amongst team members, resulting in reduced delays and enhanced productivity. With features like automated ECO and bill of materials (BOM) management, Vault keeps data accurate and accessible throughout the production process.

Autodesk Fusion Manage for lean pperations

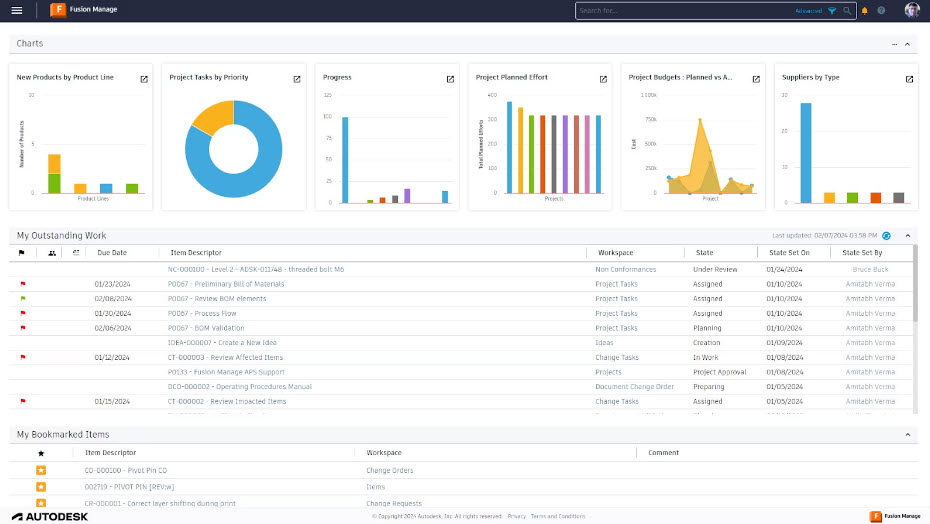

Autodesk Fusion Manage complements Vault by extending its capabilities into product lifecycle management. Fusion Manage is a cloud-based PLM solution that enables manufacturers to manage a product’s entire lifecycle, from ideation to retirement. It provides enterprise-wide access to data and collaboration across the organization – from engineering and supply chain to quality and manufacturing.

Unlock Innovation with Fusion Manage: Your Cloud PLM Solution

Empower teams, simplify processes, and enhance collaboration.

Fusion Manage automates PLM processes, such as new product introductions (NPI), approved and preferred supplier details, BOMs, and quality management. This helps reduce manual effort and improves accurate data accessibility across departments. By also automating tasks such as change requests, approvals, and supplier collaboration, Fusion Manage streamlines workflows and allows stakeholders to work with the latest data at every stage of the product lifestyle.

Fusion Manage is known for its comprehensive process template library, which includes ready-to-use templates for various business processes. These templates are handy in a lean manufacturing context, as they help standardize workflows and reduce the time spent on administrative tasks. The platform also offers customizable workflows that can be adapted to meet specific organizational needs without requiring complex coding.

Fusion Manage’s dashboards and KPI tracking tools allow manufacturers to monitor key metrics in real time. This visibility into production performance helps identify bottlenecks or areas where waste accumulates and provides actionable insights for continuous improvement. Additionally, Fusion Manage facilitates supplier collaboration through secure, real-time access to data.

Supporting lean manufacturing

Lean manufacturing thrives on efficiency, accuracy, and collaboration. By integrating Autodesk Vault with Fusion Manage, manufacturers can achieve a fully connected digital thread that spans both product data and lifecycle management. Together, these tools empower organizations to implement lean practices effectively. The end result – higher-quality products, reduced waste, and faster time to market.