& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

The digital factory revolution, founded on robust data, will drive more significant changes in the planning, design, construction, and operation of factories in the coming years than in the past century. Autodesk is here to assist companies in navigating and succeeding in this transformation across various industries and technologies.

In today’s rapidly evolving manufacturing landscape, factories are no longer just physical spaces where products are assembled. They are dynamic, data-driven environments that require strategic planning and continuous optimization. The rise of the digital factory offers manufacturers critical benefits in efficiency, innovation, and stability. However, these benefits are only fully realized when factories are treated like products themselves, with a lifecycle approach that leverages data at every stage.

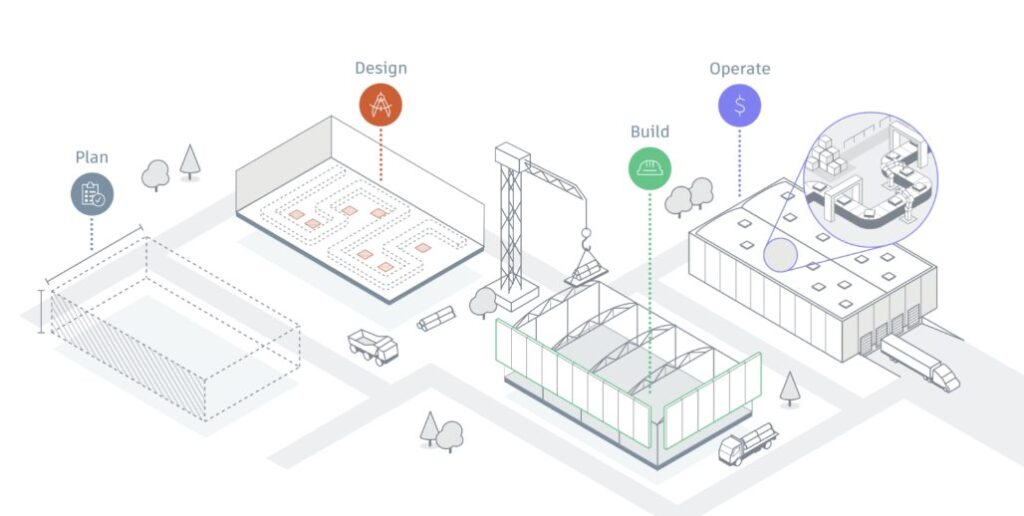

Just as products go through a lifecycle—from concept and design to production and distribution—factories, too, should be developed with lifecycle thinking. This approach involves four interconnected phases:

Traditionally, these phases have been treated as standalone, siloed processes. However, the reality is that they overlap significantly, and decisions in one phase often have unintended consequences in the next. By connecting these phases through seamless data integration, manufacturers can create a more efficient and effective development and operation process.

The prospects for digital factories have never looked brighter than today—and the opportunities are only accelerating. Imagine…

What sets Northvolt apart from other battery manufacturers is their commitment to sustainability. Founded on a mission to design the industry’s greenest battery, Northvolt relies on Autodesk’s integrated software to help their teams connect design and manufacturing through a digital factory approach.

Teams work within the Autodesk ecosystem to ensure that data is captured at every stage and that each stakeholder has full visibility into the process. Architects use Revit to design the facility, while engineers use Factory Design Utilities and Inventor to plan the factory layout. Even more, construction teams use Autodesk Construction Cloud for model management and coordination.

With a digital factory approach, Northvolt has optimized factory design to operate more efficiently and reduce costs. Ultimately, paving the way for the industry to recognize that sustainability and profitability can co-exist.

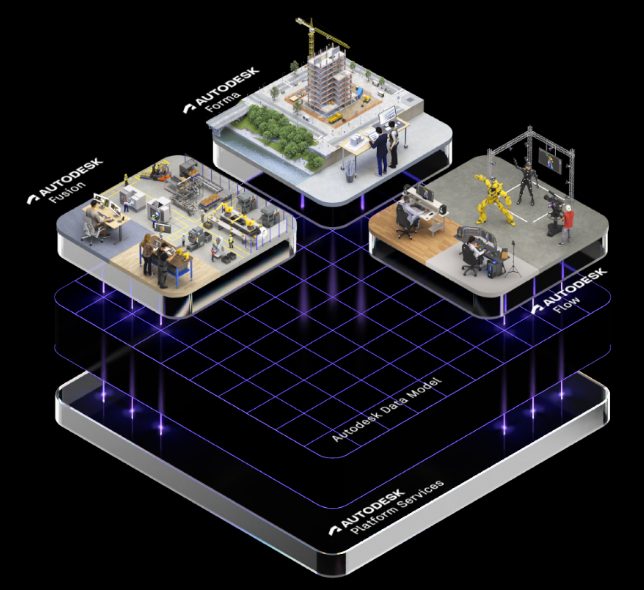

We sit in a unique position astride the intersection of several industries, including architecture, construction, and manufacturing, with technology in both building information modeling and manufacturing. And with that experience, we’re perfectly suited to help our customers.

We can help you manage, organize, and connect project data across our industry clouds, but even more importantly, across all of our cloud-based Autodesk products and third-party solutions, via Autodesk Platform Services APIs.

Currently, our data platform is already powering interoperability between Revit and Inventor, between Inventor and Fusion, and between AutoCAD and Fusion. And these relationships will only get stronger in the months and years ahead. Let Autodesk help you on your digital factory journey.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.