& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

Discrete event simulation (DES), provides a risk-free, data-driven way to experiment and evaluate changes, enhancing decision-making in the manufacturing process.

Manufacturers have numerous options to consider when trying to gain a competitive edge. These often include investing in new equipment, optimizing processes, or leveraging AI and digital transformation tools. However, the challenge becomes choosing the right combination of strategies.

Traditional methods like spreadsheets fall short due to the complexity of modern production systems, and physical studies are often impractical and costly. Manufacturers need a way to experiment and evaluate changes without disrupting production. Simulation allows for studying specific systems or entire operations, helping predict the impact of changes on production. Discrete event simulation (DES) is a proven method that uses data to forecast the effects of changes in a manufacturing system. Let’s take a look at how DES works, its advantages, its applications, and how Autodesk FlexSim can help.

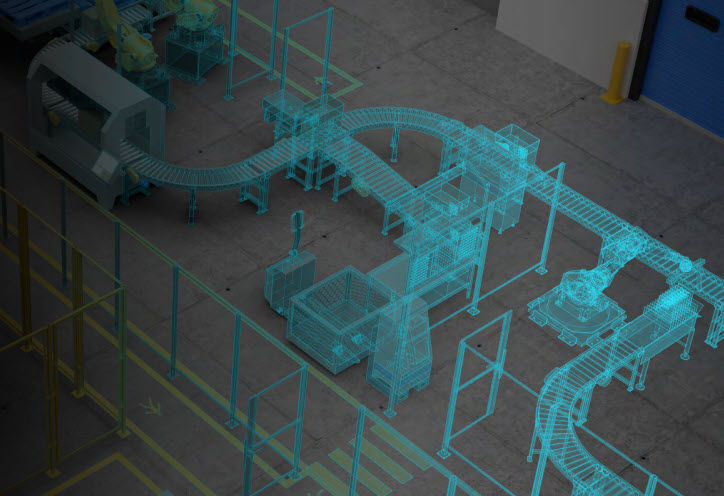

Discrete event simulation (DES) allows manufacturers to test and validate “what if” scenarios in a virtual environment using detailed process steps, current production data, and 3D visuals. This method helps uncover the best solutions without disrupting real-world production and can incorporate real-world randomness for realistic results, unlike spreadsheets.

In a digital factory, which is a shared digital model for planning, designing, building, operating, and reconfiguring a facility, DES offers insights for making better decisions quickly. It can focus on specific production areas or simulate a full production system over time, integrating real-time data for dynamic modeling, as seen in digital twin applications. DES is crucial for modern digital factories, aiding in factory design, optimizing equipment layout, and refining production scenarios during operation.

Discrete event simulation (DES) can be likened to a sandbox, providing a safe environment to test various ideas and see their outcomes. DES offers valuable data under different constraints and conditions, aiding in the planning, designing, building, and operating of a factory:

Here the top advantages of discrete event simulation (DES) for manufacturers:

1. Make accurate predictions and optimizations: Traditional evaluation methods lack accuracy and produce rough approximations. DES models enhance the detail, and prediction of complex systems, allowing for quicker and more accurate solutions.

2. Minimize risks and disruption: DES provides a risk-free environment for experimentation. This allows manufacturers to avoid trial-and-error, explore alternatives without disruption, validate strategic decisions, and prepare for future scenarios without affecting real-world production.

3. Reduce production costs: DES allows manufacturers to make accurate predictions without risking operations, identifying potential issues early, and saving time and money. It validates improvements, aligns project scope with business requirements, and predicts the impact of investments.

4. Create complex models faster: Choose a user-friendly DES solution with features like drag-and-drop layout and pre-built logic. The right software saves time, boosts efficiency, and avoids unnecessary expenses.

5. Collaborate on a complete digital representation: DES accelerates factory decision-making by clearly illustrating the current situation and potential changes. It enables easier information sharing, clarifies complex situations with 3D visuals and process steps, and supports evidence-based decision-making.

These applications represent how discrete event simulation can be extremely valuable to organizations that focus on continuous improvement:

DES helps manufacturers assess and optimize factory layouts and reconfigurations to enhance throughput and efficiency. For instance, one automotive and aerospace parts manufacturer used DES to identify that their initial factory plan would only achieve 88% of the production target. By experimenting with the simulation model, they revised the plan to meet their throughput goals.

DES helps manufacturers identify and address bottlenecks and inefficiencies. A beverage manufacturer used DES to trace a production issue to a poorly performing cartoner machine. Upgrading this equipment increased availability by 12% and improved line throughput by 30%.

DES validates proposed investments, preventing poor decisions. A pharmaceutical manufacturer used DES to increase production from 15 to 25 batches per week. The simulation revealed that dispensing, not blending, needed improvement, avoiding an unnecessary $50 million equipment purchase and increasing throughput to 20 batches per week.

DES excels at manipulating time, allowing manufacturers to speed up processes for long-term estimates or slow down events for detailed analysis. For instance, a delivery company used DES to simulate over a year of truck deliveries in under a minute, optimizing their delivery schedule to avoid a bottleneck at a TSA-controlled gate.

Manufacturers rely on innovation to solve factory problems. DES supports this by validating unconventional or unproven ideas. By simulating a production area, teams can evaluate numerous ideas for efficiency, throughput, cost, or other metrics, eliminating guesswork and trusting the results.

Autodesk FlexSim is a great solution for discrete event simulation (DES) due to its powerful and user-friendly features designed to meet the diverse needs of modern manufacturers. FlexSim offers an intuitive drag-and-drop interface, enabling users to easily create complex models without the need for extensive programming knowledge. This ease of use, combined with pre-built logic objects and a code-free environment, significantly reduces the time and effort required to develop accurate simulations. By simplifying the modeling process, FlexSim empowers teams to focus on analyzing and optimizing their systems, leading to more informed decision-making.

“The FlexSim model allowed us to do optimization runs where we could zero in on how many people we needed on each level and how big a pick wave we can run.” -John Friedl, Senior VP of Automation and Industrial Engineering, ThredUp

In addition, FlexSim’s capabilities extend beyond basic simulation. It provides realistic 3D visuals and detailed process steps, which help teams visualize and understand the intricacies of their operations. This visual clarity is critical for communicating complex scenarios across an organization. As it ensures that stakeholders at all levels understand the potential impacts of proposed changes. Further, FlexSim’s data-driven approach enhances the accuracy of predictions and optimizations, allowing manufacturers to validate strategic decisions with confidence. Whether it’s for planning, designing, building, or operating a factory, Autodesk FlexSim delivers the comprehensive tools needed to improve efficiency, reduce costs, and increase overall productivity.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.