& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5 min read

Mechanical design software is crucial in product development, enabling engineers to create, analyze, and refine products efficiently.

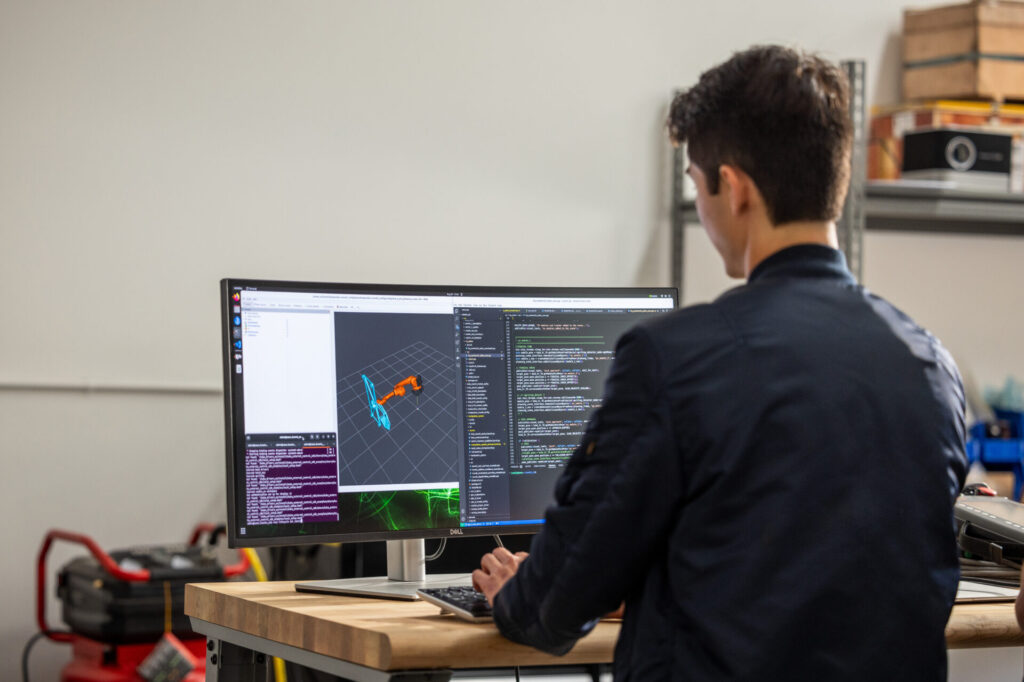

Mechanical design software is an indispensable tool in product development. It offers features to streamline and enhance the design process, allowing engineers and designers to create, analyze, and refine their products with precision and efficiency. Autodesk Inventor, a powerful software that boasts an array of tools specifically designed to address the multifaceted needs of mechanical design.

Mechanical design software is a type of computer-aided design (CAD) software that designers and engineers use to create, modify, analyze, and optimize mechanical designs. It offers a virtual environment where users can develop detailed 2D and 3D models of mechanical components, systems, and assemblies. It is an essential tool in the engineering and manufacturing industries, facilitating the creation of everything from small machine parts to complex machinery and large industrial systems.

Mechanical design software allows for the creation of highly detailed and accurate models, reducing errors and the need for physical prototypes. It provides the ability to visualize and manipulate designs in a virtual environment ensuring that every detail is accounted for before moving to the manufacturing stage. Ultimately, this saves time and resources, while significantly minimizes the risk of costly mistakes.

It also allows for the automation of repetitive tasks and accelerates the design process, saving time and resources. By streamlining workflows and eliminating manual processes, mechanical design software allows engineers to focus on innovation and problem-solving. The automation features reduce the burden of repetitive tasks, enabling faster project completion and allowing companies to bring products to market more swiftly.

Mechanical design software also allows for better communication and collaboration among team members, irrespective of location. In today’s work environment, teams are often in various geographic locations. With a centralized platform team members can collaborate in real-time, share updates, and provide feedback. This enhances collaboration and ensures everyone is in alignment with project goals.

Designers can also simulate and analyze the performance of their models under various conditions, leading to better-informed design decisions. The ability to test and validate designs in a virtual environment helps identify potential issues early in the development process. This proactive approach allows for design optimization, ensuring the final product meets all performance and safety requirements.

Further, documentation tools ensure all aspects of the design are well-documented and standardized. Accurate documentation is a critical piece of the manufacturing process, compliance, and future reference. The generation of detailed drawings, specifications, and reports, ensures all stakeholders have access to the necessary information for successful project execution.

Mechanical design software is a used across various industries, helping engineers and designers to create, analyze, and modify mechanical systems and components. One of the primary industries that utilize mechanical design software is the automotive industry. It’s used to design everything from individual parts to entire vehicles. Engineers model components, run simulations to test perfomance, and make sure that everything fits together correctly before physical prototypes are made. This helps speed up development, while reducing costs and enhancing the final product’s safety and efficiency. Mechanical design software also helps the automotive industry in the creation of more fuel-efficient engines, safer car structures, and advanced features like autonomous driving systems.

The aerospace industry also relies heavily on mechanical design software. In this field, precision and reliability are critical, given the extreme conditions and safety requirements of air and space travel. Aerospace engineers use mechanical design software to design aircraft, spacecraft, and satellites, to ensure all components meet performance and safety standards. The software allows for detailed simulations of aerodynamic properties, structural integrity under various stresses, and the behavior of materials in different environments. By using advanced modeling and simulation capabilities, aerospace companies can innovate faster and with greater confidence. Additionally, industries such as manufacturing, robotics, medical device development, and consumer electronics also leverage mechanical design software to bring complex, high-quality products to market efficiently and effectively.

Autodesk Inventor includes a comprehensive suite of features that cater to the diverse needs of mechanical design. Here’s how some of its key features can help achieve your design goals:

Precise, powerful, and ready for innovation with Autodesk Inventor.

Autodesk Inventor allows for the creation of complex sheet metal parts, which can be unfolded for manufacturing and then refolded to check fit and functionality. Bend tables help standardize bend allowances, maintaining consistency across parts. The flat pattern export feature generates flat patterns for laser cutting, punching, or other sheet metal manufacturing processes.

This feature allows for the creation of structural frames using standard profiles, reducing the time spent on repetitive tasks. Designers can also create custom profiles and save them for future use. Automatic mitering and end treatments ensure proper fit and assembly, simplifying the frame design process.

Inventor offers efficient routing tools for cables and harnesses, ensuring optimal paths and minimizing interference. Libraries of electrical components simplify the design process, and accurate documentation, including wire lists and connection reports, supports manufacturing and assembly.

Auto-routing in Inventor automatically routes tubes and pipes through assemblies, reducing design time and errors. Designers can use standard fittings or create custom ones to suit specific needs, and accurate bills of materials (BOMs) ensure all components are accounted for during manufacturing.

Inventor allows for the design and preparation of parts for welding, including creating weld beads and fillets. Detailed weld annotations help maintain clarity and precision during manufacturing, and weldment analysis helps verify strength and durability.

This feature simplifies the process of adding bolted connections by automatically selecting the appropriate bolt type and size. Users can also design for preloaded bolts to ensure assemblies meet performance and safety standards and perform strength analysis on bolted connections to verify their integrity under load.

Component generators quickly create standard mechanical components such as shafts, splines, gears, and springs. Users can customize components to meet specific design requirements, and performance analysis ensures reliability and efficiency under various conditions.

The adoption of mechanical design software is essential for any organization looking to stay competitive in today’s fast-paced market. The precision, efficiency, and collaborative capabilities offered by these tools enable companies to innovate and deliver superior products. Autodesk Inventor, with its extensive feature set, is an invaluable asset for engineers and designers, empowering them to achieve their design goals and drive the future of product development.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.