A digital twin in manufacturing creates real-time, dynamic virtual replicas of physical objects, systems, or processes, leveraging IoT, AI, and data analytics for detailed simulations and predictive analyses. This technology significantly enhances product design, predictive maintenance, operational efficiency, quality control, and sustainability.

In the rapidly evolving landscape of Industry 4.0, the concept of a digital twin has emerged as a pivotal innovation driving the future of manufacturing. A digital twin is a virtual replica of a physical object, system, or process that exists in real-time, enabling a seamless integration of the physical and digital worlds. This advanced technology leverages the Internet of Things (IoT), artificial intelligence (AI), and data analytics to create detailed simulations that mirror the characteristics and behaviors of their real-world counterparts.

What are digital twins?

A digital twin is a virtual representation of a physical object, system, or process, existing in real-time and continuously updated with data from its real-world counterpart. This dynamic model is created using technologies such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics, allowing it to mirror the physical entity’s characteristics, behavior, and performance accurately. Digital twins enable comprehensive simulations and predictive analyses, providing insights into the lifecycle of an asset. This constant feedback loop between the physical and digital realms allows for real-time monitoring, problem identification, and the optimization of processes. This ultimately leads to enhanced efficiency, reduced downtime, and cost savings. Digital twins are instrumental in improving product design through virtual prototyping. This helps ensure consistent quality control and predictive maintenance by forecasting potential failures. Digital twins also support better resource management and sustainability practices by optimizing energy consumption and reducing waste.

Benefits

The adoption of digital twin technology in manufacturing offers numerous benefits, including:

1. Enhanced product design and development

Digital twins improve the design and development processes by enabling virtual prototyping and testing. Engineers can simulate different scenarios, identify potential issues, and optimize designs before physical production begins. This reduces the time and cost associated with traditional prototyping.

2. Predictive maintenance

Digital twins can predict potential failures and maintenance needs as they continuously monitor the performance and condition of machinery and equipment. This preventative maintenance approach minimizes downtime, extends the lifespan of assets, and reduces maintenance costs.

3. Improved operational efficiency

Digital twins provide real-time insights into manufacturing processes, allowing for the identification of inefficiencies and the implementation of process improvements. This leads to optimized production lines, reduced waste, and increased efficiency.

4. Enhanced quality control

Digital twins help ensure consistent product quality as they simulate and monitor manufacturing processes. Any deviations from the desired specifications can be detected and corrected promptly. This reduces the risk of defective products reaching the market.

5. Cost savings

Gaining the ability to simulate and test virtually helps manufacturers avoid costly mistakes and optimize resource allocation. This yields significant cost savings throughout the product lifecycle.

6. Sustainability

Digital twins contribute to more sustainable manufacturing practices by improving resource management, reducing waste, and optimizing energy consumption.

Applications of digital twins in manufacturing

Digital twins have a range of applications in manufacturing, improving various aspects of production and operational management. In Product Lifecycle Management (PLM), digital twins provide a comprehensive view of a product’s lifecycle, from initial design and development to production, operation, and eventual disposal, helping to manage and optimize each stage.

For production planning and optimization, manufacturers utilize a digital twin to simulate and streamline production processes. This includes layout planning, workflow optimization, and scheduling, thus ensuring that production lines operate at most efficiently.

In supply chain management, digital twins offer real-time visibility. Manufacturers can track inventory levels, monitor supplier performance, and optimize logistics. This results in more efficient and responsive supply chain operations. Within smart factories, digital twins facilitate the integration of IoT devices, sensors, and automation systems. This creates a connected ecosystem where real-time data is used to monitor and control manufacturing processes, leading to increased automation and efficiency.

Performance monitoring and analysis benefit from digital twins by providing detailed and accurate representations of machinery and equipment performance, which allows for continuous monitoring and data analysis. This enables the identification of performance bottlenecks and significantly improves operational efficiency.

What’s the difference in a digital twin vs. a simulation?

A digital twin and a simulation are both invaluable tools in engineering and manufacturing, yet they serve distinct purposes and functionalities. A digital twin is a real-time, dynamic virtual representation of a physical object, system, or process, continuously updated with data from its real-world counterpart. In contrast, a simulation is a virtual model that replicates the behavior of a system or process under various conditions. Simulations are typically static or based on predefined scenarios, lacking real-time data updates. They are used to test hypotheses, evaluate performance, and predict outcomes without impacting the actual physical system, often during the design and testing phases to identify potential issues and optimize designs. Both tools are essential in manufacturing; however, digital twins offer a more comprehensive, real-time approach, while simulations provide valuable insights through controlled, scenario-based testing.

The future of digital twin technology in manufacturing

The future of digital twin technology in manufacturing is set to change the industry, driving unprecedented levels of efficiency, innovation, and sustainability. As digital twins become more sophisticated, their integration with advanced technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT) will allow for even more precise and predictive modeling of manufacturing processes. These enhancements will help manufacturers anticipate and mitigate potential issues before they occur, significantly reducing downtime and maintenance costs. Even more, the ability to simulate and optimize production lines in real-time will lead to more agile and responsive manufacturing operations, capable of adapting quickly to market demands and disruptions.

Digital twins will also play a crucial role in advancing sustainable manufacturing practices. By providing detailed insights into resource usage and waste, they will help companies optimize their operations for minimal environmental impact. The integration of digital twins with blockchain technology could also enhance supply chain transparency and traceability, ensuring ethical sourcing and production practices. As the technology evolves, digital twins will become more accessible to small and medium-sized enterprises, democratizing advanced manufacturing capabilities. In summary, the future of digital twin technology in manufacturing promises a smarter, more efficient, and sustainable industry, where data-driven decision-making and continuous optimization are the norms.

Autodesk solutions

Autodesk Inventor offers advanced 3D modeling and lifecycle management capabilities essential for modern engineering and manufacturing. Its comprehensive CAD tools help to create precise and detailed models, forming the foundation of digital twins. Lifecycle management ensures continuous insights from design to maintenance, allowing for optimization at every stage. Inventor’s interoperability with other Autodesk products and IoT platforms facilitates real-time data integration, keeping digital twins up to date with the physical asset’s current state. Collaboration features support teamwork across disciplines, and cloud-based services like Autodesk Forge enhance data storage and analysis capabilities. Customization and automation options streamline updates and task management, while high-quality visualization and documentation tools ensure clear communication of digital twin insights to all stakeholders.

Enhance Your Engineering Workflows

Precise, powerful, and ready for innovation with Autodesk Inventor.

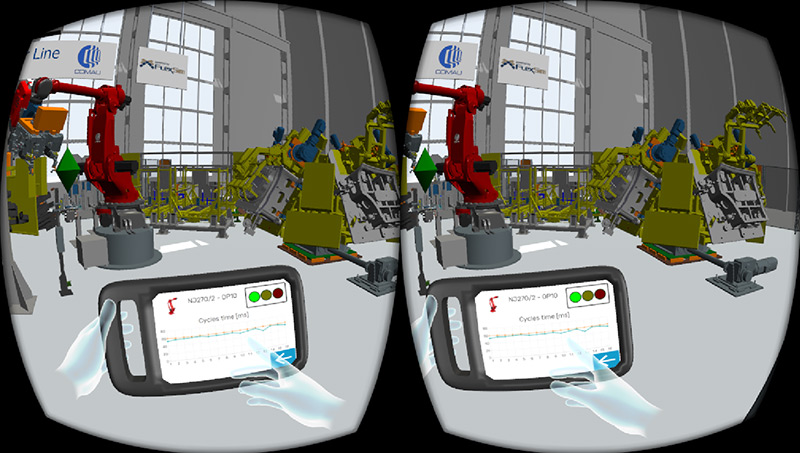

FlexSim is an outstanding digital twin in manufacturing solution due to its ability to help you quicly create accurate simulation models. Its advanced features cater to any digital twin application, with an open architecture that facilitates auto-building models from raw input data. FlexSim offers robust database connectivity for seamless data import and export, essential for digital twin data processing. Advanced communication features, including a RESTful HTTPS API and extensibility through DLLs and the Module SDK, enhance its functionality. FlexSimsupports AI and machine learning, providing tools for training reinforcement learning algorithms. With VR capabilities, users can view simulation models in virtual reality with a simple one-click option, enhancing visualization and interaction.

FlexSim: 3D Discrete Event Simulation Software

Easy-to-use 3D simulation modeling and analysis software with high-end capabilities. Predict and optimize production processes with realistic 3D visuals and data-driven scenarios.

Digital twins empower manufacturers and industries to make data-driven decisions, innovate faster, and achieve higher operational efficiency, marking a significant advancement in the realm of Industry 4.0. By creating virtual replicas of physical assets and processes, manufacturers can achieve higher levels of efficiency, quality, and sustainability. As the manufacturing industry continues to evolve, embracing digital twin technology will be essential for staying competitive and driving innovation.