& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

8 min read

Working with large assemblies in Inventor can get complex. Let’s dive into 10 tips that will help you work more efficiently.

As designs become larger and more complex, they consume more computing time. As a result, you may notice your load times are increasing as your assembly grows. You may even receive out of memory errors, experience poor graphics performance, or it takes entirely too long to create your drawing views and annotations.

Why is this happening? Well, it can be due to a number of reasons including:

Let’s dive into some common scenarios and top tips for working with large assemblies in Inventor.

It’s natural to want to add as much detail as possible when creating parts. However, do you really need all of that detail in the main assembly as you are working? What exactly is the impact of adding a lot of detail? Take the part above as an example: observe the progression of adding features to the part. You can see the highly simplified part on the left and the impact at each stage of adding new 3D modeling features. Complexity doesn’t increase significantly until you begin adding numerous faces, such as with a helicoil cut or extruded text. The part is not just four times larger; it can become 50 times larger. So, consider the impact of some of the features you are adding to your parts and take into account the best practices that will give you the results you are looking for.

When you need very complex features for operations, model states can be a great solution. It’s an excellent way to manage parts that have both machined and casted versions. It is also useful for families of parts, such as different sizes of fasteners, or for quickly displaying sheet metal folding operations in a model or drawing view. Model states help with alternate assembly positions, like an air cylinder that is extended or retracted. Model states can also be used to simplify parts or subassemblies. When you create a simplified model state, it can then represent that simplified version in the main assembly or subassembly.

When referring to model states in drawings there are a few things to look out for. For instance, you can display different model states per view, which is a great option when you need it. However, when your assemblies become very large, you may want to handle this differently, as each model state used in a drawing act like a copy of the data. Instead of using model states for different views, consider using different view representations or create a separate drawing for each model state. This approach can help manage data size and complexity more effectively.

Use the Simplify command to reduce the number and cost of components in large assemblies. There have been some great enhancements to the Simplify command and user interface. Within the command, there is an option to create a substitute part, which is a fantastic tool for collaborating with customers on various types of projects, including BIM model creation. Substitutes can also be an excellent way to simplify an assembly, resulting in a simplified part that remains associative to the assembly or subassembly it was derived from. It is not necessarily recommended to create substitutes early in the design process when heavy design work is ongoing. It’s more common to do this later when the design is near completion.

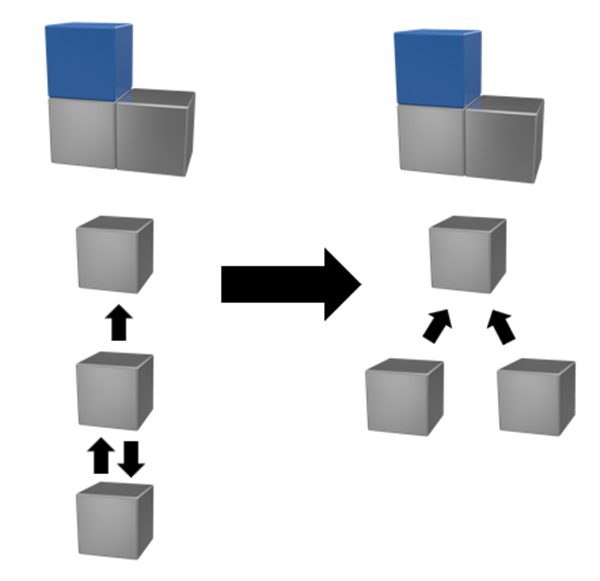

Adaptivity is a valuable method for designing around other components in an assembly environment. It allows you to associate elements like hole alignment or general relationships that are maintained from one part to another. However, in a large assembly environment, it’s recommended to avoid overusing adaptivity. Keep in mind that the relationships created between components must periodically recalculate, which can impact performance. If you do use adaptivity, make sure that your parts are related to a top-level component. As shown in the image on the right, avoid cascading relationships where Part C relates to Part B, and Part B relates to Part A. Additionally, try to avoid cyclic relationships between components where two features are related to each other. When adaptive relationships are not a concern, it makes sense to turn adaptivity off.

Next, let’s look at your assembly browser and examine how you are structuring your assemblies. Are you taking advantage of the benefits of using subassemblies? It’s best practice to combine parts into subassemblies because this results in fewer top-level constraints that need to be calculated. The constraints within a subassembly do not have to be recalculated at the top level; they can be assumed to be calculated the same as a rigid object, unless you decide to change the subassembly to flexible. You can also have subassemblies inside subassemblies, with the depth being up to you. Generally, it is advised not to go too deep, but doing so should not affect performance.

With constraints, it’s important to fully define the location of your components as much as possible to reduce the degrees of freedom in your design. Even more crucially, if you over-define components, make sure to resolve the conflicts as you work, as conflicting constraints will impact performance. You can fix errors manually or use tools such as the Design Doctor to guide you through the process of editing, deleting, or suppressing constraints. Additionally, you can right-click on a constraint with a warning to find the Recover tool, which can help address the issue.

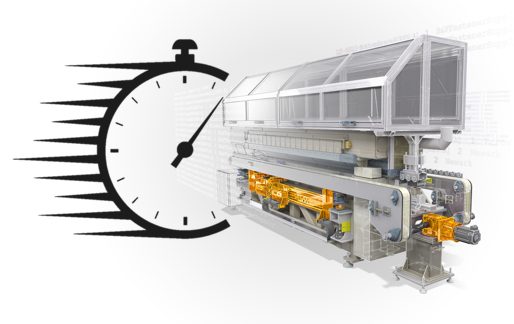

Let’s talk about express mode. What is it? Usually, when you open an assembly, it fully loads all of the component data into memory. For large assemblies, you can open them in express mode, where only the component cached graphics are loaded into memory. This cached graphics data is saved from the fully loaded model, allowing you to use express mode later, which enables you to load your assemblies several times faster. So, why not open everything in express mode? The reason comes down to what you want to do when it’s open. You can do a lot in express mode, especially with recent enhancements, but some features will require you to fully load the model. You may notice that models are automatically loaded based on the features or commands you are using, which is an on-demand load workflow and a big improvement from the early phases of express mode.

Remember that express mode was released nine years ago, and a lot has changed since then. Significant work has been done to improve the experience, so if you haven’t used it in a while, it would be worth looking into the enhancements made by the Inventor development team. One last thing: if your team is using express mode, make sure you are all using the same settings for consistency.

In express mode, you can place components, add constraints or joints, create and edit components in place, use section view, create and edit work features, pattern a component, copy or mirror a component, and manage assemblies and representations.

As you know, the parts and subassemblies are reference files that need to be stored and maintained. What is the best way to save those files? A flat folder structure works best when possible, where you save all files in one folder. This approach makes it easier for Windows to find referenced files in the main assembly. Some designers follow this method, while others may find it impractical and use subfolders instead. The idea is to make that subfolder structure as flat as possible. Another rule of thumb is to keep the number of parts in a folder to 800 or less. Additionally, there is a Windows limit of 10,000 files in one folder.

There are a number of things you can do with projects and libraries to optimize your workflow. Set the Included File path option to point to a single, read-only project file maintained on the network by the CAD administrator, and make sure all users have access to that project file. Never locate a workspace on a network location; it is best practice to open your models and drawings from a local directory instead of a network.

Additionally, avoid cross-referencing workspaces or library locations with another workgroup, as mapped network drives can slow down the machine’s ability to open and save files due to Windows attempting to resolve these every time. Keep the relative paths set to true, meaning paths should be relative to the location of the project file. The fewer workgroup search paths defined, the better, as fewer search paths improve file searches. If your projects require portability, be sure to define all storage locations as subfolders of a project folder, which contains only the project file.

And there you have it, 10 ways to make working with large assemblies in Inventor less stressful. Keep your eye out for more tips on this topic coming soon.

Precise, powerful, and ready for innovation with Autodesk Inventor.

Haven’t had a chance to try Inventor? Start with a free 30-day trial today.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.