& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

6 min read

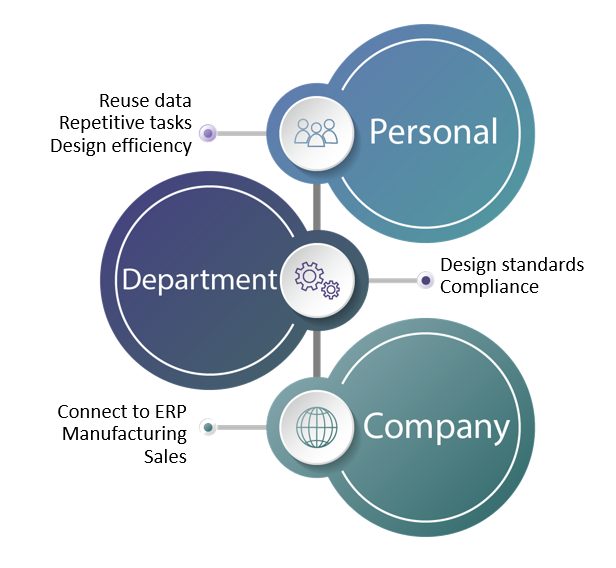

Design Automation tools boost innovation, streamline manufacturing, and reduce repetitive tasks, helping meet customer demands for customizable products and protecting profit margins. Autodesk Inventor’s automation capabilities allow for scalable solutions that enhance efficiency and productivity across personal, team, and company-wide levels, with efforts easily repurposed for larger projects.

Automation tools help tackle common problems by boosting innovation, helping you win more business, making manufacturing smoother, and cutting down on repetitive tasks. They help you meet customer demands for customizable products and solve issues like outdated tech that can slow you down. Plus, automation can help protect your profit margins from competition and make sure valuable engineering knowledge is well-documented, so you don’t lose expertise when key employees move on.

In this article, we’ll discuss automation at all levels: personal software use, team tasks, and company-wide initiatives like connecting engineering and business systems. Design automation grows with you and your company, having a positive impact on big and small tasks alike. Your automation journey is scalable, meaning work done on small projects today can be repurposed for larger automation efforts later. You should never lose the effort you put into a project.

Design automation refers to the use of software tools and technology to automate repetitive and time-consuming design tasks. This allows designers and engineers to focus on more creative and complex aspects of their work. By leveraging algorithms, artificial intelligence, and machine learning, design automation can optimize design processes, improve accuracy, and accelerate project timelines. Various industries, including architecture, engineering, and manufacturing, use design automation to enhance productivity, reduce errors, and ensure consistency. As a result, design automation helps organizations achieve greater efficiency, innovation, and competitiveness in their respective fields.

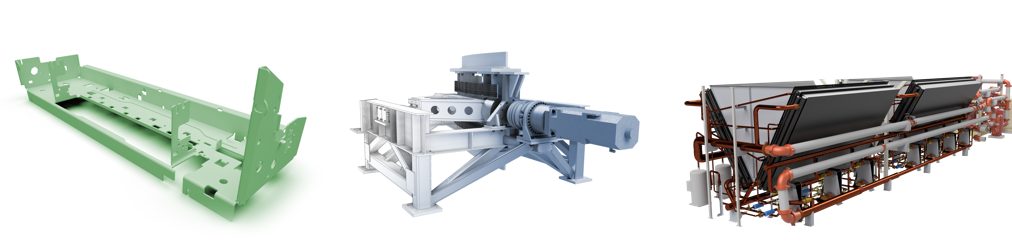

Design automation in 3D modeling with Autodesk Inventor makes designing easier and more efficient. It’s not just about moving from 2D to 3D; it’s about using automation to save time and work smarter. Inventor helps you predict how your designs will behave and lets you build intelligence into your models. Any changes you make update everything else automatically, like manufacturing drawings and CAM toolpaths. There are also specialized tools for different model types, like sheet metal, frame design, and tube and pipe, which simplify the process and ensure accuracy.

Autodesk Inventor offers powerful tools for designing and developing sheet metal components, automating many aspects to save time and ensure accuracy. These tools adhere to your defined standards, such as sheet metal thickness, bend allowances, corner treatments, and unfolding rules, ensuring your designs meet manufacturing requirements. Features like flange, hem, fold, punch tool, and corner treatments streamline the creation and modification process. Standard 3D modeling tools like rectangular pattern and mirror also aid in quick development. When creating a flat pattern, Inventor performs all necessary calculations based on your standards, providing an accurate 2D profile. Additionally, Inventor Nesting groups similar materials and thicknesses into individual sheets, optimizing efficiency based on parameters you set. These tools help you develop precise sheet metal components and seamlessly connect your designs to manufacturing processes.

Autodesk Inventor simplifies frame design by automating the process of creating welded frames. You start by drawing line segments and then select cross-sections, their locations, and angles. The tools allow for easy insertion of frame members from a library of standard profiles, with options for placement, offset, and rotation. Once the frame members are positioned, corner treatments like trimming, mitering, and notching can be applied, and end caps can be added. Inventor also includes fast and easy structural analysis to test for stress, deflection, and bending moments without the need for creating and solving a solid mesh. This ensures your frame design meets performance requirements quickly and efficiently.

Autodesk Inventor streamlines the design and documentation of piping and tubing systems by offering tools for route creation, component placement, and automatic updates. It includes a library of standard fittings, flexible routing options, and interference detection, ensuring accurate and consistent designs. The feature generates detailed documentation and a bill of materials, integrating seamlessly with other Autodesk tools like AutoCAD Plant 3D and Navisworks. This automation enhances efficiency, accuracy, customization, and cost savings in complex piping system projects.

Autodesk Inventor’s Content Center streamlines the process of adding standard components to your assemblies. It offers a library of over 750,000 parts like nuts, bolts, bearings, and gears. You don’t need to model these parts yourself; simply select what you need, and Inventor will size and place them for you. Design Accelerators help create specialized components, and built-in engineering calculators provide essential tools from your machinery handbook. Content Center supports various international standards and integrates with Inventor’s design tools. This allows for the quick generation and automatic placement of components. Ultimately, you’ll save time and increasing efficiency in your design process.

iLogic, is a powerful rules-based design engine in Autodesk Inventor. It allows for the creation of forms and configurable models that simplify the design process. Users can input data through various methods like input boxes, radio buttons, slider bars, and pull-down menus, and even see images for clarity. As users fill out these forms, their answers drive the parameters and variables in the iLogic rules, making it easy to configure new designs without knowing specific values. The iLogic rules editor is user-friendly, guiding users similarly to VB.net, with a learning curve that becomes intuitive over time.

Creating forms involves dragging variables into the editor. When a new product is configured, existing simulation setups and CAM toolpaths are retained and can be recalculated. This results in quick analysis of high-stress areas and updated manufacturing paths. The process finishes with assembly drawings and automatic bill of materials.

Product configurators save engineering time and boost sales of custom products. Setting up a configurator in Inventor is straightforward with iLogic technology, requiring no specialized programming. Users define the logic, create intuitive forms, and organize parameters, rules, and properties. Inventor Nastran allows for advanced analyses directly within the CAD environment, automating the simulation process for faster results.

The Inventor API and Visual Basic.NET offer endless automation possibilities, extending beyond configuring new designs to automating entire engineering processes. The powerful API allows you to automate nearly any function available in Inventor’s user interface. This includes automating repetitive tasks, setting up design rules, checking drawings, and integrating with ERP and MRP systems. You can even create custom add-ins for Inventor.

Precise, powerful, and ready for innovation with Autodesk Inventor.

“We are now over 10 times the size that we were when we started all of the automation.”

“In the next five years, we are going to grow from 100 million dollars a year in revenue to 500 million. Automation is critical for scaling at the rate that we are going. We would not be able to do the things we are doing today and looking into the future without the Autodesk tools.” – ViewRail

Design automation efforts in Autodesk Inventor can vary in scale. The work you do today can be leveraged for larger projects in the future, ensuring no effort is wasted. The tools provided in Autodesk Inventor support a comprehensive automation strategy, covering all your needs.

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.