& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

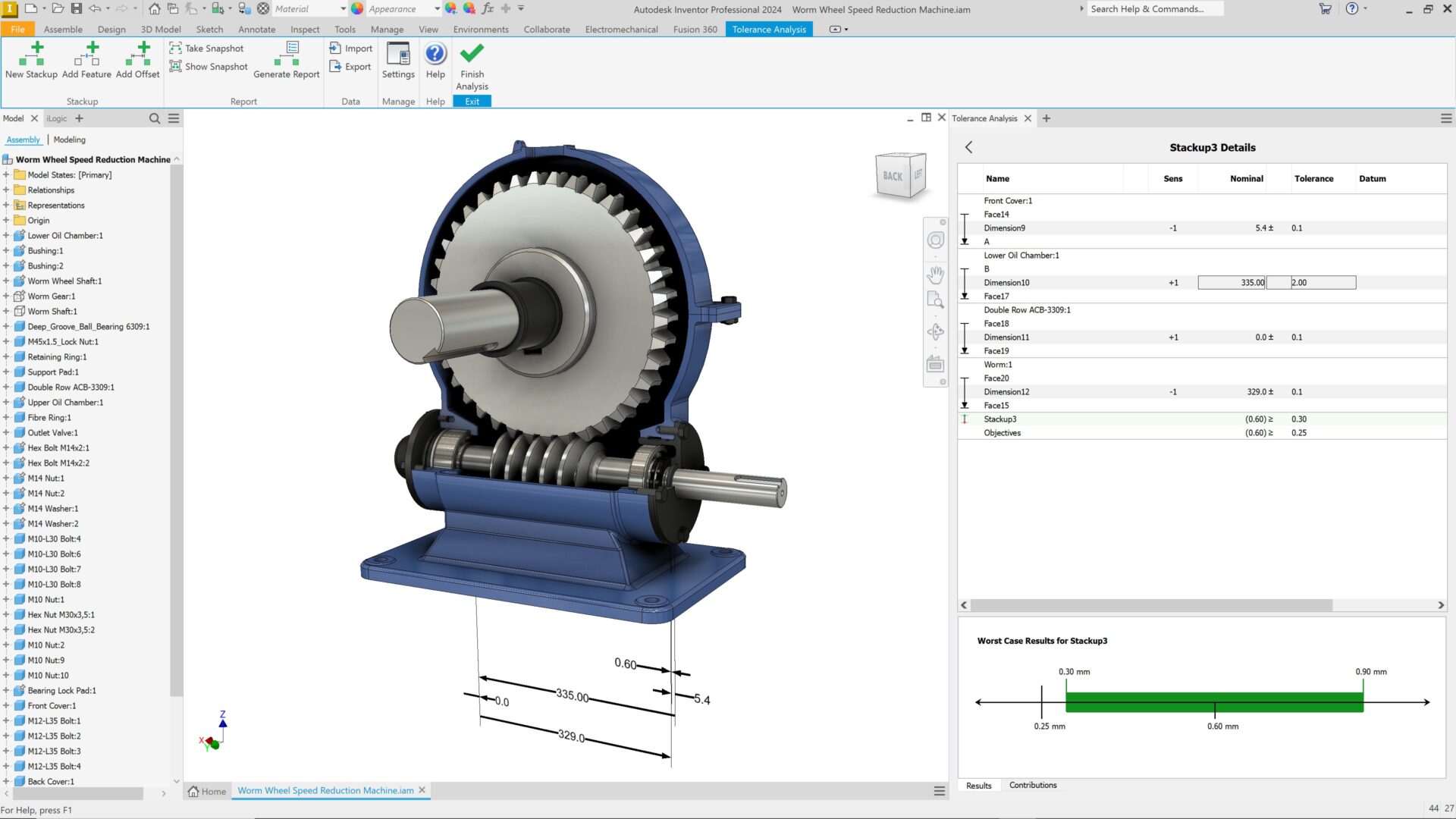

Discover the value of simulation software in design and engineering, its applications across industries, and how Autodesk Nastran and Autodesk Fusion provide powerful tools for optimizing product design and manufacturing. Through advanced modeling and analysis capabilities, simulation allows for thorough evaluation of designs under realistic conditions, unlocking efficient problem-solving, cost reduction, and product innovation. Let’s…

Design & Engineering

The integration of 2D and 3D workflows using AutoCAD and Inventor enhances productivity, quality, and competitiveness by enabling a seamless design process, improving collaboration, and automating tasks. The integration of 2D and 3D workflows is crucial for enhancing productivity, product quality, and market competitiveness in manufacturing. AutoCAD and Inventor, offer powerful capabilities that, when used…

Design & Engineering

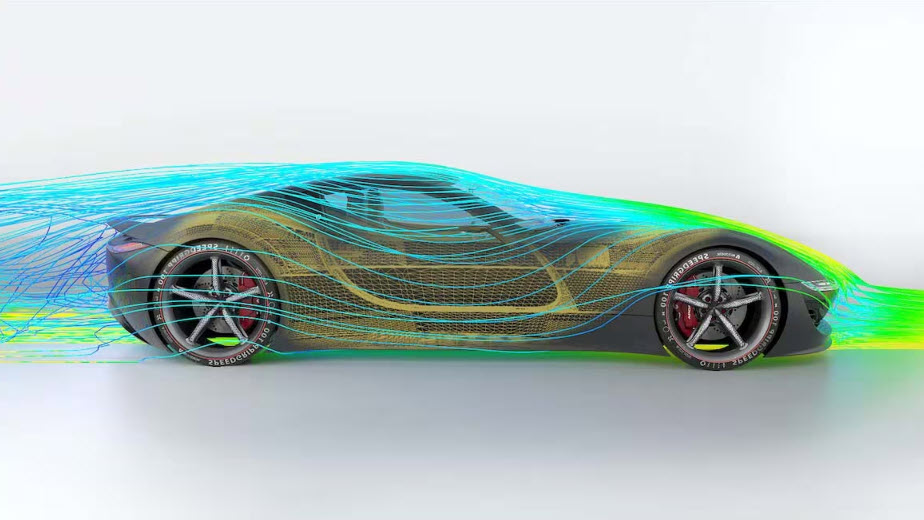

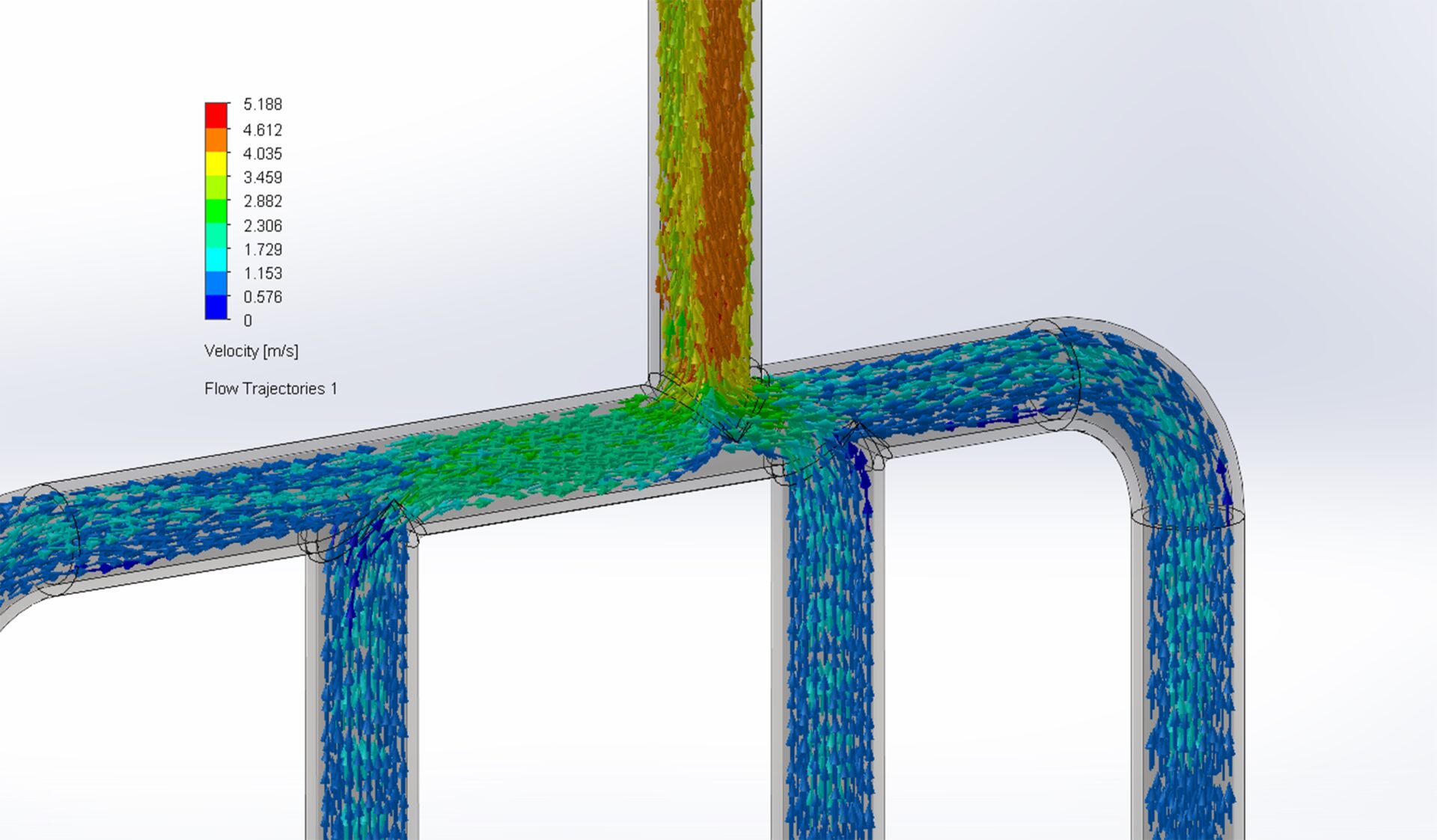

Understand exactly what flow simulation is, its importance in design and manufacturing, and how Autodesk solutions can help.

Design & Engineering

Explore the benefits of model-based definition (MBD), its benefits across manufacturing, and how Autodesk solutions can help. In the ever-evolving landscape of manufacturing, model-based definition (MBD) is emerging as a transformative approach that enhances efficiency, accuracy, and collaboration. This blog explores what MBD is, its benefits in manufacturing, its practical applications, and why Autodesk Inventor…

Design & Engineering

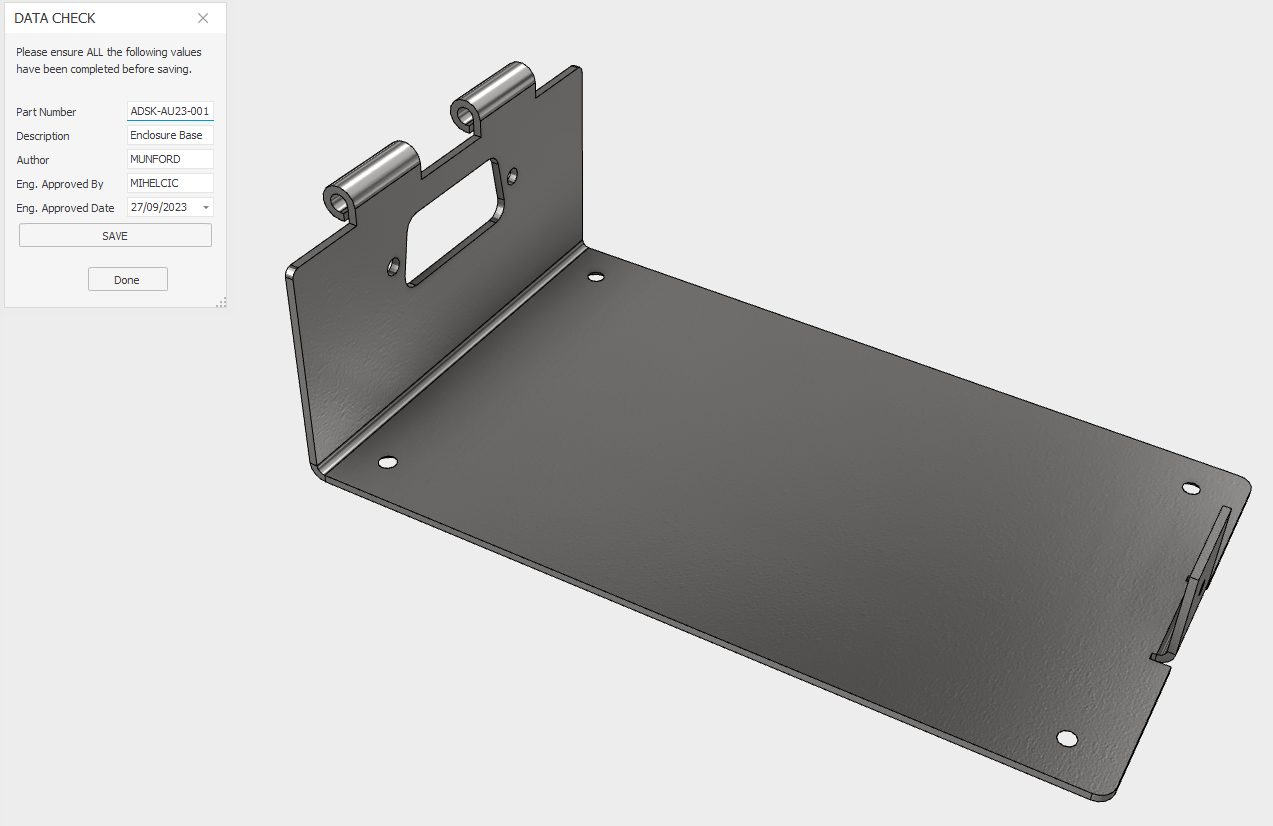

Discover how Autodesk Inventor iLogic can help with consistent data entry for crucial iProperties in preparation for BOM, Partlist, or data transfer to a PLM or ERP system.

Design & Engineering

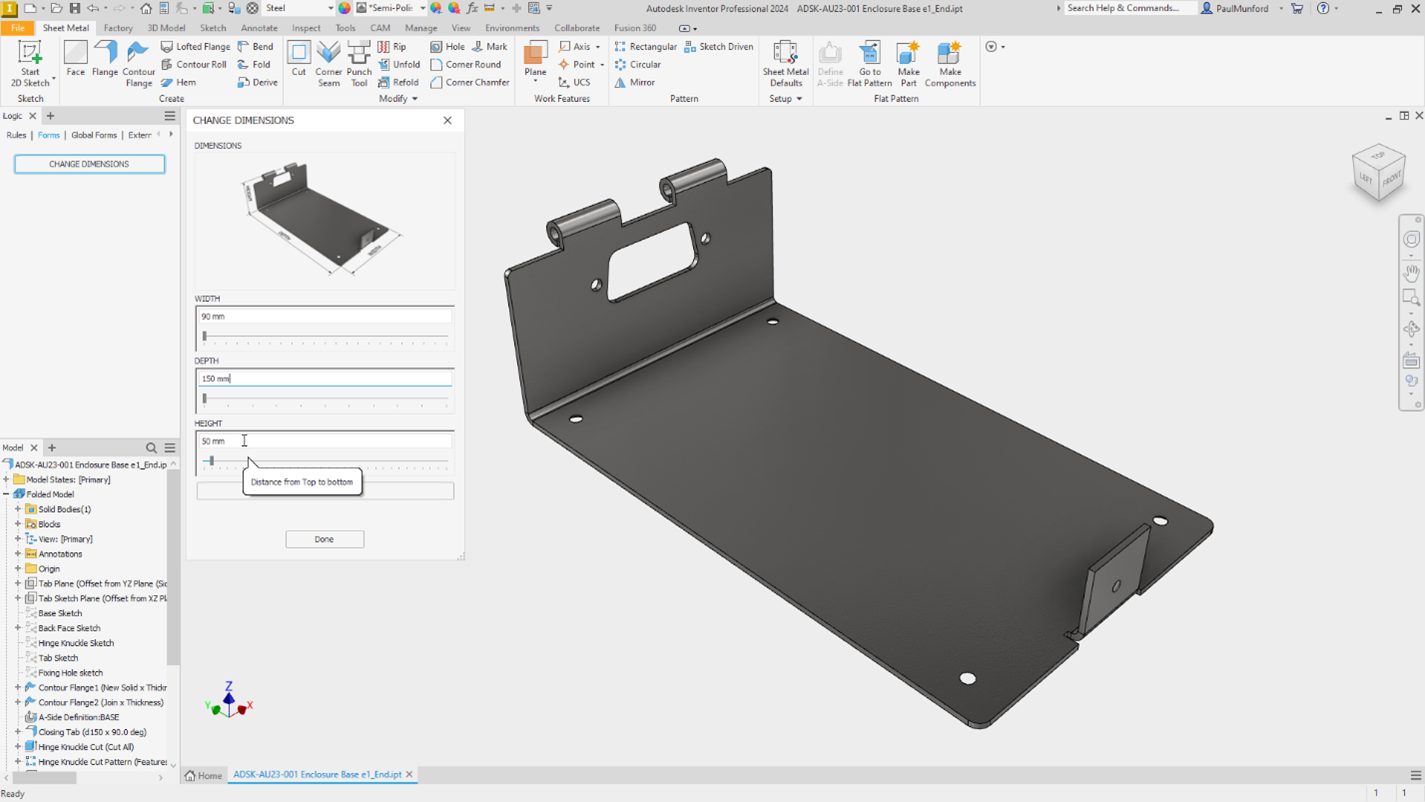

Unleash the power of Autodesk Inventor with these five iLogic hacks designed specifically for non-programmers. Discover how to build on the intelligence in your design to create configurable models and automate processes. This blog post will guide you on how to efficiently communicate design intent by adding an input form using iLogic. Learn step-by-step how…

Design & Engineering

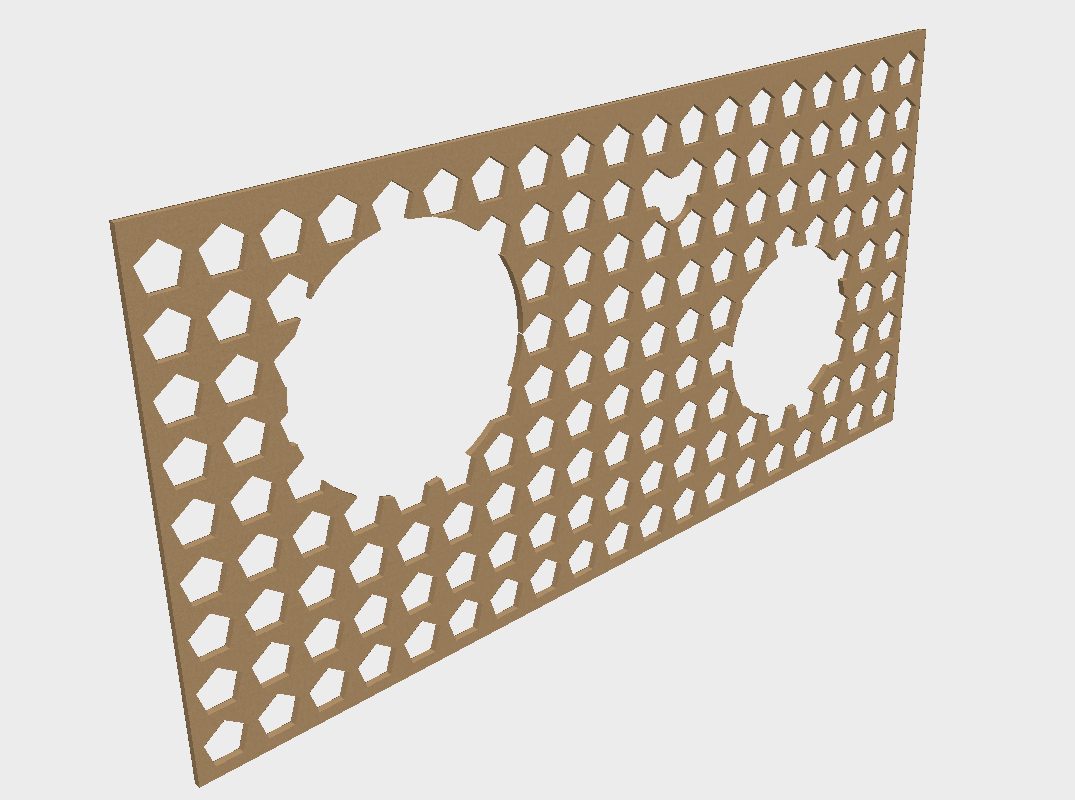

Understand how the 'Optimized compute' option in Autodesk inventor patterns can speed up pattern generation, and reduce file size on disk.

Design & Engineering

You believe that good design and engineering can solve any problem. So do we. Explore design and engineering case studies and tutorials from the AU design and make conference to learn more.

Design & Engineering

‘Failure in creating a flat pattern.’ Who needs it? No one wants to create an Autodesk Inventor sheet metal part that won’t unfold! This article by Paul Munford gives tips and tricks to garentee your sheet metal models will unfold every time

Design & Engineering

A middle school robotics team in Michigan is discovering the power of 3D modeling with help from Autodesk Inventor software. Led by a parent with no previous engineering experience, the team uses the software to visualize concepts, build 3D models, test prototypes virtually, and 3D print parts. This middle school team is bringing their ideas…

Design & Engineering

The Inventor team works hard to develop the tools that promote efficiency in your design and manufacturing workflows. Many of the tools we implement in Inventor begin with the great ideas we receive from designers and engineers who use our software. Your complete success is a combination of the software that helps your ideas take…

Design & Engineering

This year marks a monumental milestone for 25 years of Autodesk Inventor, a quarter of a century of designing and making your best products. This release brings over 142 enhancements, each carefully crafted to improve user experience, enhance functionality, and streamline design processes. We’ve also tackled over 1330 bug fixes, demonstrating our commitment to reliability and…

Design & Engineering

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.